cnc machine operating CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product. TRILAND METALS LIMITED - Free company information from Companies House including registered office address, filing history, accounts, annual return, officers, charges, business activity

0 · work instruction for machine operator

1 · cnc operator what is it

2 · cnc machine setup operator

3 · cnc machine process step by

4 · cnc machine operator meaning

5 · cnc machine operator description

6 · cnc machine operations list

7 · cnc machine operation basics

Explore aluminum tread plate at Metal Supermarkets. Ideal for slip-resistant flooring & decorative projects in various industries. Get aluminum diamond plate cut to size today.

By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand . A CNC operator produces machined parts by programming, setting up and operating a computer numerical control (CNC) machine. Maintaining equipment, adhering to quality and safety standards and keeping .

machine cnc prix

A CNC operator is responsible for preparing and setting up CNC machines for operation. This process involves reading blueprints and mechanical drawings to understand the specifications of the task at hand. CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product. Understanding the intricate operations of CNC machines involves a blend of mechanical insight and software proficiency. Here’s a breakdown to simplify the complexity: Blueprint Analysis: CNC operators commence by .

Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and .

lynda - sheet metal with solidworks enclosure design project

Computer numeric controlled (CNC) machines are critical in the operations of the manufacturing industry. These machines cut, shape and finish raw materials into finished . What does a CNC operator do? A CNC operator pushes buttons to keep the CNC machines running while performing basic inspection of the machined parts. As an entry-level position, all of the skills necessary for a CNC operator to possess would be taught to a . By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand the duties and responsibilities of a CNC machine operator. A CNC operator produces machined parts by programming, setting up and operating a computer numerical control (CNC) machine. Maintaining equipment, adhering to quality and safety standards and keeping detailed part records are some of the core responsibilities of a CNC operator.

m9050 junction box bluetooth

A CNC operator is responsible for preparing and setting up CNC machines for operation. This process involves reading blueprints and mechanical drawings to understand the specifications of the task at hand.

CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product. Understanding the intricate operations of CNC machines involves a blend of mechanical insight and software proficiency. Here’s a breakdown to simplify the complexity: Blueprint Analysis: CNC operators commence by studying blueprints or CAM files to determine the machine path, cut speed, and feed rate 1. Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and troubleshoot common programming errors. Computer numeric controlled (CNC) machines are critical in the operations of the manufacturing industry. These machines cut, shape and finish raw materials into finished products, and they require the input and skills of CNC machinists to operate optimally.

CNC machinist operators ensure the smooth operation of CNC machines, involving tasks from initializing programs to monitoring and adjusting machines, and they are instrumental in producing high-quality parts in manufacturing.

The role of a CNC operator is to set up and operate CNC machines and equipment. The operator unloads raw materials, prepares a test run, another role, and ensures that a well-functioning machine is working. An operator’s day-to-day responsibilities differ depending on the parts they specialize in.

What does a CNC operator do? A CNC operator pushes buttons to keep the CNC machines running while performing basic inspection of the machined parts. As an entry-level position, all of the skills necessary for a CNC operator to possess would be taught to a . By mastering these skills and consistently applying best practices, CNC machine operators can significantly enhance productivity, reduce errors, and contribute to the overall efficiency of manufacturing processes. Understand the duties and responsibilities of a CNC machine operator.

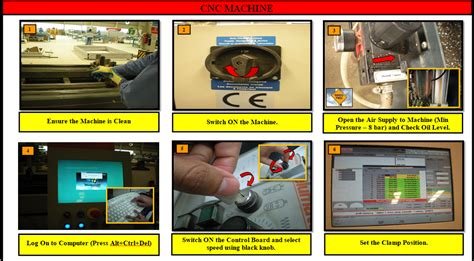

work instruction for machine operator

cnc operator what is it

A CNC operator produces machined parts by programming, setting up and operating a computer numerical control (CNC) machine. Maintaining equipment, adhering to quality and safety standards and keeping detailed part records are some of the core responsibilities of a CNC operator.A CNC operator is responsible for preparing and setting up CNC machines for operation. This process involves reading blueprints and mechanical drawings to understand the specifications of the task at hand.

CNC machining is a subtractive manufacturing process that involves removing part of a workpiece using instructions from a CAD model to make a product.

cnc machine setup operator

Understanding the intricate operations of CNC machines involves a blend of mechanical insight and software proficiency. Here’s a breakdown to simplify the complexity: Blueprint Analysis: CNC operators commence by studying blueprints or CAM files to determine the machine path, cut speed, and feed rate 1. Learn the basics of G-code and M-code, which are the standard programming languages used in CNC machining. Understand how to write and edit CNC programs, input the necessary commands and variables, and troubleshoot common programming errors. Computer numeric controlled (CNC) machines are critical in the operations of the manufacturing industry. These machines cut, shape and finish raw materials into finished products, and they require the input and skills of CNC machinists to operate optimally.

CNC machinist operators ensure the smooth operation of CNC machines, involving tasks from initializing programs to monitoring and adjusting machines, and they are instrumental in producing high-quality parts in manufacturing.

m a c metallic lipstick pale rose 10 oz boxed

lyon cabinet steel drawer dividers

Introducing the American Made Stainless Steel Triple Glove Box Holder from Omnimed, a reliable and trusted source in industry-leading glove box holders. This convenient choice is 10 inches high by 16 inches wide and 3 and ¾ inches deep, making it perfect for any wall, cabinet or flat surface.

cnc machine operating|cnc machine setup operator