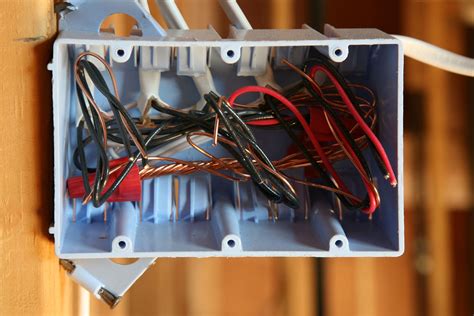

metal recepticle box vs plastic BX cable is a type of metal-clad, armored cable. Learn the basics of armored BX . Metal roofing sheets are incredibly durable and made from recyclable materials such as zinc, aluminum, copper, and tin. These materials are environmentally friendly. Metal sheets are fire-resistant and have outstanding insulating .

0 · wiring plastic electrical boxes

1 · wiring plastic electrical box knockouts

2 · plastic vs metal electrical boxes

3 · plastic or metal electrical boxes

4 · plastic junction boxes electrical lowe's

5 · metal vs plastic gang box

6 · metal versus plastic electrical box

7 · are metal electrical boxes safe

Types of Sheet Metal. Commonly used sheet metal materials can be divided into two categories, which are: Galvanized steel; Stainless steel; Galvanized steel. Galvanized steel can be mainly divided into: Electro-galvanized sheet; Hot-dipped metallic-coated sheet; Let’s compare the above two galvanized sheets of steel through a table.

Strong, fireproof, and incapable of melting, metal boxes offer the greatest level of security for all electrical wiring applications. Compared to plastic boxes, metal electrical boxes are very strong: It is virtually impossible to bend, warp, twist, or crush metal electrical or junction .15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .BX cable is a type of metal-clad, armored cable. Learn the basics of armored BX .

A locknut-type clamp is the classic metal cable clamp with a short, threaded .Metal vs. Plastic Electrical Boxes Most electrical boxes are either metal or . Plastic boxes are the most common choice for residential wiring projects. They are lightweight, easy to install, and less expensive than metal .The biggest difference between metal and plastic electrical boxes is their durability and strength. Metal boxes are stronger and more durable, making them ideal for heavy-duty applications, while plastic boxes are more lightweight and .

Although plastic rises in popularity as its quality increases, there are still some situations where a metal electrical box will be the preferred option. Here are the pros and cons of a metal cover. Pros. Metal is an incredibly .

wiring plastic electrical boxes

Unlike electrical or breaker panels, which are nearly always made of steel, electrical boxes can be constructed of metal or plastic. Depending on the circumstances of how they'll be used, one material can be preferable to the other. Metal and plastic are the most common materials used to construct electrical boxes. Metal boxes are primarily made from steel, aluminum, or cast iron, while non-metallic boxes . Plastic boxes are lightweight, easy to work with, and suitable for non-metallic cables. They are a popular choice for DIYers. On the other hand, .When it comes to electrical installations, choosing the right type of enclosure is crucial for safety and functionality. Metal boxes and plastic boxes are two common options available, each with .

Metal vs. Plastic Electrical Boxes Most electrical boxes are either metal or plastic. Metal boxes are generally steel, while plastic boxes are PVC or fiberglass.

wiring plastic electrical box knockouts

Grounding is a big plus in metal boxes. Most switches and better quality receptacles will ground directly through the yoke to the box, where with a plastic box you have to connect a ground wire separately. The whole house has it's wiring terminated to metal outlet boxes currently. A friend is helping me with the wiring portion and swears we should use plastic boxes for this project. He states using the metal boxes will be a hassle since wiring needs to be grounded to the box and then the actual switch/outlet. He says the metal box

The problems are not specific to an outdoor location. They are for any use. Top 10 reasons metal boxes are better than plastic boxes: Metal completes a circuit. So if a hot wire comes loose, it will short and trip a breaker when it touches the side of the box, letting you know there is a problem and becoming safe in the process.

A signifigant advantage to wrapping the outlet w/ tape is to prevent shorting one of the receptacle screws to a metal box. As far as metal boxes and NM.NM has been run to metal boxes for a very long time. Plastic boxes are a fairly recent addition in the history of wiring. IMHO, I prefer metal boxes. Plastic or metal box should be okay. The problem with plastic boxes is that you need a ground wire connected to the outlet/switch, metal boxes it is usually an option(the box becomes a ground path). Both types of boxes are made to mount to studs. Turning off the power is the best idea, some people don't.

Fiberglass vs. Plastic boxes. Jump to Latest 8K views 23 replies 15 participants last post by Brianrayl Jun 11, 2022. MHElectric Discussion starter. 8321 posts I prefer em because the connectors fit better, they mount without flexing or distortion, and mounting the box flush to the stud with the appropriate size mud ring is easier than mounting the plastic box with the exact 1/2” or 5/8” extension from the stud face. When it comes to electrical installations, the choice between a metal or plastic junction box depends on the unique requirements of your project. Plastic boxes are cost-effective and lightweight. They are widely used for standard residential and low-voltage applications. Metal boxes are durable, fire-resistant, and good for grounding. They are used in demanding .

house metal front door gates

Set them the correct depth and go. Metal boxes need a proper depth plaster ring and make it harder when a DIY cuts the drywall due to the rounded edges. Plastic boxes and NM are about twice as fast to install over metal. Plastic have the built-in nail vs needing screws to secure a metal box or stapling the box to a stud. All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayhomerepairs Do you feel comfortable using metal electrical boxes on your DIY elect.

6) Conductivity: Metal outlet box vs Plastic . Metal Junction Box: Metals ( such as steel and aluminium) contain free electrons which can roam within the structure and are easily able to transfer current. In general, metals are good electrical conductors, because their conductivity lies between 106 to 108 S/m.In this article, we’ll take a closer look at the differences between metal and plastic electrical boxes and help you determine whether you should go for a metal or plastic electrical box.. Whether you’re a professional electrician or a DIY enthusiast, we’ve got you covered with all the information you need to choose the right type of electrical box for your project.As we are learning to install a quality electrical product during our apprenticeships, we are constantly reminded to bond our metallic boxes. But why do we b.

Metal boxes intrinsically bond the screws so they aren't an unbonded path to substrate. They also intrinsically bond switches, which in Canada means the switch doesn't need to be wire-bonded (not acceptable for receptacles though)Doesn't matter plastic or metal just use the appropriately sized box for the number of wires. Also use what makes the most sense. If I'm doing a simple junction I use plastic. When I have a lot of wires I use metal, easier to use. Make sure you put a cover on the box when your done. Plastic boxes are definitely allowed but I don't know if only specific cases. I finished by basement about a month ago and hired a Licensed Electrical Contractor to run the electrical. The LEC used metal boxes in 99% of the wiring but then used a blue plastic box for the GFCI receptacle on the wet bar counter.WRONG. Believe it or not, a common misconception is that a metal supply box is fire-rated. While a metal outlet box won't burn, what it doesn't do is slow down a fire, which is basically what a firewall is intended to do. Most fire-rated outlet .

house metal roof install

Should I purchase plastic or metal boxes to add a new receptacle? I have a book and it tells me to go with plastic as opposed to metal. . note: you still have to ground inside the plastic boxes as well as the outlet because the ground screw in there grounds the strap for when say a switch (that normally doesnt have a groundscrew) is used.The box is probably too small for the wire, The wire is cut short, The plastic box is flexed. I would replace that b plastic cover with something else though. They probably have better plastic covers than a crappy wall plate. I'm planning on putting an electrical box in my sink base with a split outlet, one for the dishwasher, the other for the garbage disposal. I was thinking of running 12/3 MC from the wall gangbox (metal box + metal cover with knockout) to another metal box in the sink base. The scenario I'm thinking of would be a weatherproof plastic box with GFI's and a metallic in use cover. . this requirement is met by attaching the equipment grounding conductor to the yoke of the receptacle. cowboyjwc Moderator. . Unlikely to be energized does not relinquish the requirement. Besides, the only metal cover on a box that is .

As far as selecting an actual box, from experience, I recommend getting a 2-gang plastic box (or something equivalent in size if you want to use metal). The larger the capacity the better because a NEMA 14-30 receptacle with four #10 wires is not only bulky, but can be a very stiff pain to manipulate.Figure no 3 플라스틱 정션박스. 2) Durability and Longevity: Metal junction box vs plastic 금속 정션 박스: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term.; Plastic Junction Box: Plastic junction boxes are not so sturdy, so not suitable for outside areas. Metal vs. Plastic Electrical Boxes . Most electrical boxes are either metal or plastic. Metal boxes are generally steel, while plastic boxes are PVC or fiberglass. Metal Electrical Boxes . . An outlet box and a junction box can be the same thing. A junction box is a standard electrical box that encloses wire splices and contains no device .

Source: Jatumeth Susukh/ Shutterstock.com Metal vs. Plastic Junction Boxes There are two types of junction boxes in common use today: metal junction boxes and plastic junction boxes.Both have their own advantages, and both are useful for certain applications. For many applications, the biggest advantage of a metal junction box is its durability. Metal junction . Correct. In a metal box, the ground wires from the cables go to the box's grounding screw first. Then, the switches pick up ground via their mounting screws, and receps pick it up either through a "self-grounding" feature against the screw threads, or via hard flush metal yoke-box contact, or via a ground pigtail to the screw or a clip. I current have plastic wall boxes. I need to connect to a MC conduit, which connects to an metal handy box with an receptacle. (NM to receptacle is not appropriate in this case). I also have another 2 gang plastic wall box which needs to be connect to a FMC conduit attached to a cooktop. Can I use a two gang extension ring with knockouts?

plastic vs metal electrical boxes

Sheet metal welding is a crucial fabrication process because it is one of the simplest ways to join cut-out pieces of metal sheets to create the desired shape. In Sheet metal welding, the mating surfaces are subjected to intense heat to fuse them by melting the metal in a designated area.

metal recepticle box vs plastic|metal vs plastic gang box