cnc router parts vs pro cut A guide to the various router bits used on CNC routers aimed at complete beginners. Include tips for which bits are the most important to get first. When using the GMAW method to weld copper, it is recommended that you use ERCu copper electrodes. The use of Aufhauser Deoxidized Copper is also recommended; this is a copper alloy or filler .

0 · The Best CNC Routers for Precision Craftsmanship

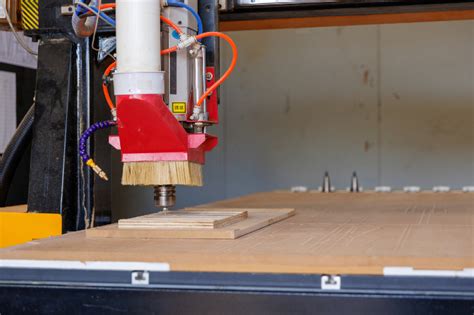

1 · Standard or Pro

2 · Cutting Aluminum with a CNC Router: The Hobbyist’s

3 · CNC router parts standard vs pro

4 · CNC Router vs Mill: What’s the difference?

5 · CNC Router vs Mill: Every Difference Explained

6 · Best Router Bits for CNCs in 2024 (All Budgets)

7 · Beginner's Guide to CNC Router Bits

8 · 8 Best 4x8 CNC Routers in 2024 (All Budgets)

Stick welding sheet metal can be done by welding DC electrode negative with 20-40A which is about the the lowest amperage settings that still allows to strike an arc. Suitable electrodes are E6011 for rusty or painted .

In terms of machine stiffness, the PRO system has a bit of an edge over the standard system -- functionally you can cut faster, despite the fact that the PRO has slightly more gantry clearance (~8" instead of 6.5" on the standard).

If I'm looking at doing some hobby work (10-20hours/week) on a cnc, would I be ok with the CNC router parts standard, or would I need their pro series. I would be working with . A guide to the various router bits used on CNC routers aimed at complete beginners. Include tips for which bits are the most important to get first.The whole package will cost you under 0 (assuming you have an air compressor), so if you use your router reasonably often it’s a really smart upgrade. While it definitely is my preferred way to cut it, there are a few . The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall material blocks, and are more rigid and .

Overall, CNC routers are less expensive and for projects with larger parts, less rigid materials, and three-dimensional cuts. In contrast, a CNC mill can create smaller and accurate parts, handle harder materials, and come . The size and weight of a CNC router play an important part. Although bigger CNC routers are more powerful and efficient, you still need to consider how much space you have for your CNC router. Smaller and lighter .

High-end 4×8 CNC routers with accurate servo systems have a 0.01-0.02 mm accuracy in various cuts, while cheap 4×8 CNCs are far less accurate – often between 0.05 and 0.5 mm (0.002”-0.02”). Cheaper 4×8 CNC .FoxAlien comes with an offline controller but I'm probably going to use Octopi to control either CNC. Anyone else doing this? Sainsmart appear to have a better "eco system" having a mini vice, replacement spoilboards. Does any have any experience with either CNC or company? How is the build quality / customer support? Thanks, Mark

I am planning to buy a cnc router in the next few months. Budget is flexible to an extent but I'd like to stay around 00 to get started. Onefinity is off my list for overall cost vs features for the moment. Primarily I am comparing a longmill mk2 and the shaepoko 5 pro.

I’ve been thinking about getting the queenbee pro full kit for a few weeks now and just wanted some other options for Cnc routers around a similar price. Im coming over from the 3d printing realm so most of it has been pretty easy to learn. However insight from people with experience is much appreciated! Pilot Pro CNC machine is a user friendly machine for cutting and shaping tools. You can use it to cut and shape light Aluminium parts and shapes or if you would like, you can also use it for working on wood. Pilot Pro CNC is not the only one that can work on aluminum, there are several different CNC routers that you can use for working on aluminum IS vs Pro What are the differences between the two from a practical standpoint. . I was even considering one of the extruded aluminum setups like CNC Router Parts, but I just don't know how rigid they are. For my setup, it may be good enough. . Right now I am using a CO2 laser to cut 6mm acylic, and prep the edges with a router table before .

Shapeoko 5 Pro is a high-performance CNC Router that comes with everything you need to accurately cut wood, plastic, and aluminum so you can turn your workbench into a business. Shapeoko 5 Pro CNC Router Rigid, Accurate, & Reliable Shapeoko 5 Pro uses hardened linear rails and ballscrews for increased productivity and accuracy.With the CNC, it needs to be securely attached to the bed. And with a CNC, the spindle noise and bit chewing on wood will have you wearing earplugs. With a laser, I can watch a hockey game easily at the same time as it’s working. The CNC can also have issues with tear out due to wood grain, but there’s workarounds for that.I bought the QueenAnt 1515 pro v2. They upgraded the x axis and it is pretty substantial. You can't get a 1515 Onefinity I don't think. The ball screws, linear rails and hybrid steppers make this machine better than most and I would say that the price can't be beat. everything except the box for the electronics and a contractor & breaker is included.Modular Machine Design. Designed for your needs: From 2'x2' to 10'x30' and beyond; Built in your space: Avid CNC machines fit where others can't; Future Proof: Expandable platforms grow with your business; Versatile: Rotary, Hybrid Router+Plasma, Laser - include now or add later

What is the general wisdom on when to use a climb cut vs a convetional cut? Top. rscrawford Vectric Wizard Posts: 1107 . Model of CNC Machine: Home Built 4-axis Router Location: Fort Collins, CO. . GENERAL rule of thumb in solidly mounted workpiece and "controlled" cutter motion and zero backlash machine parts is to do climb cutting. A hand .CNC Router parts provides excellent DIY options usable for both a router/mill and a plasma torch holder. . Best tools to pair with a CNC router (assuming access to rough cut lumber) are: . Prusa Pro HT90 is here: The Only 3D Printer an Engineer Needs .im a noob when it comes cnc machining and i want to buy a 3018 pro cnc and some router bits , my goal is to modified enough to i can cut aluminum at decent speeds so in stock configuration can u recomend me feeds and speeds for plywood, acrylic, and mabey 6061-T6 aluminum? . If you have to cut a slot, use an endmill smaller than the slot, and .AVID CNC, formerly CNC Router Parts. I shopped around for a long time for a plasma table, and got the chance to check out some nice industrial/Prosumer models (a friend of mine owns a business that is based around metal fabrication). AVID nears the material and parts quality of units triple the price with it's DIY/ assemble on site approach.

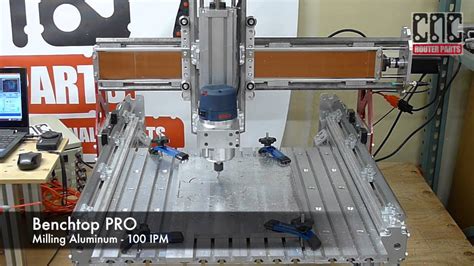

1-you want to cut metal at least some of the time 2-you’re looking for a 2’x2’ work envelope at minimum 3-you’re willing to build it yourself If these are true, v wheels and belt drive should be off the table as options. Bang for your buck, build your own Avid pro clone or mpcncI'm in the market for a new CNC router for milling plastic, wood and some aluminum. . Avid CNC Benchtop Pro 2424 vs. Axiom Basic AR4 Rigidity . I'm in the market for a new CNC router for milling plastic, wood and some aluminum. .

3020 PRO MAX Much better spindle and construction that should help it with more intricate designs Higher Z-axis height which can't be easily upgraded on the 3018 Larger starting working area, but I haven't seen any parts to easily upgrade it more than that Decently more expensive at 0 Any thoughts or ideas would be greatly appreciated. So, today we will discuss and compare two such CNC routers, namely: the 3018 and 3040 CBC routers. The 3040 CNC router is similar to CNC 3018, featuring high-quality material cutting and available at a cost-effective .It will be interesting to see what Avid decides to be when they grow up. They started life as CNC Router Parts, and now they are primarily a kit machine seller. Will they morph again, or, will they be the exact same. Right now, it's hard to put them in a box. The have B to B prices, but a B to C sales and support model. Model of CNC Machine: DIY 4' x 8' CNC Router/Plasma Location: Shingletown . climb cuts tends to make parts larger and conventional smaller. so I use both for most things climb to get most of the way and a cleanup pass conventional to cut through and make it accurate. solid wood can blow out doing a climb cut so I usually offset the cut .

Originally under the CNC Router Parts name, we became Avid CNC in 2019. Simply put, we're avid about CNC, and we think our name should reflect that! . Layering The first strategy we suggest is to cut your part in layers, with CNC'd indexing holes to align the layers. This requires far less z travel, and also removes risk by turning a long .

The Best CNC Routers for Precision Craftsmanship

FoxAlien Masuter Pro CNC Router Machine, Upgraded 3-Axis Engraving All-Metal Milling Machine for Wood Acrylic MDF Nylon Carving Cutting - Amazon.com. . spills, and broken parts, as well as breakdowns (plans vary) 24/7 support when you need it. Quick, easy, and frustration-free claims. Cover this product: 3-Year Protection Plan .99. Learn moreWorkholding Shapeoko 5 Pro is based on our Hybrid Table that includes T-slot workholding and a set of clamps to go with it.. Fit Full-Sized Sheets Shapeoko 5 Pro is available in 2 and 4-foot widths, so you can fit standard-sized sheets into the machine without cutting them.There's additional room on either side for clamps to hold everything in place.

In this guide, we will discuss a detailed comparison between CNC mill vs. router and how these machines differ in price. . CNC routers are designed to cut through softer materials such as wood and plastic and typically operate along three axes. . CNC milling machines help manufacture parts and products that help in the production industries .The IQ Pro ATC Tabletop CNC Router comes equipped with tool changing capabilities making it a very versatile machine. . Parts & Accessories Videos Resources Close Resources Open Resources . How to Use VCarve With A Vector File | IQ CNC Router Quick Cut. Making a Wooden Guitar Body on a Desktop CNC Router | Laguna Tools. IQ Pro CNC with ATC . CNC routers vs mills: The article compares the differences between CNC routers and CNC mills, two types of machines that can cut complex shapes from materials.; Structure and movement: CNC routers have a gantry design where the spindle moves on the X, Y, and Z axes, while the workpiece remains stationary.CNC mills have a table that moves on the XY plane, .

Creating various kinds of parts has become a cakewalk because of the different CNC machining techniques available these days. Two common techniques that may often collide are CNC router vs laser cut.. In this article, we will go through the differences between these techniques to help you choose the perfect technique for your project needs.

With this setup and a 1/8" two flute carbide endmill and no coolant I can do 1.5mm depth of cut, 1.5mm width of cut, and ~400mm/min feedrate (climb cut) in 6061-T6 Al which is pretty much as fast as I'm comfortable watching it cut! First off, some notes about the stock 3020 Pro Max and why I sought to upgrade it.

thermwood cnc parts

Top 10 Best Metal Fabrication Welding Shop in Austin, TX - November 2024 - Yelp - Affinity Metalworks, Welder of Texas, Jcer Welding Construction, MetalWork Austin, Austin Laser Fab, Pacheco's Custom Welding, Cen-Tex Plating Company, Eric's Mobile Welding Service, Total Precision Welding and Fabrication, Astro MechanicsSelect, plan and demonstrate sustainable metal fabrication operations using industrial metal fabrication machinery and emerging technologies. Perform basic technical measurements and .

cnc router parts vs pro cut|Cutting Aluminum with a CNC Router: The Hobbyist’s