methods of joining metals in fabrication Here we will take a look at the main methods of materials joining; adhesives, mechanical fastening, and welding. 1. Adhesive Bonding. Adhesive bonding uses bonding chemicals to stick two or more parts together. It can be used to join . MIG Welding Automotive SheetmetalThis clip from howtoASAP.com is from a 52 minute video featuring nationally recognized automotive builder, Craig Hopkins. Wh.

0 · temporary fixing examples for metal

1 · sheet metal joining techniques pdf

2 · sheet metal joining screws

3 · sheet metal joining process

4 · sheet metal joining methods

5 · permanent methods of joining metals

6 · five methods of joining metals

7 · different joining methods for metal

This lot consists of one piece of a er-Knapp #619-9-US4 steel, satin brass-plated (US4), non-handed, cabinet door stay (typically used overhead). The overall length of the slotted arm is 9", and the center-to center length of the arm with swiveling foot is 7-11/16".

Two standard methods employed for metal joining are Welding and Fabrication. In this comprehensive guide, we will dive deeper into metal joining, exploring the welding and metal fabrication processes, their differences, .Permanent joining methods include soft soldering, brazing, gas or oxyacetylene welding, arc welding, friction welding, the use of adhesives, and more. Each joining method has its own advantages and considerations, meaning that .Here we will take a look at the main methods of materials joining; adhesives, mechanical fastening, and welding. 1. Adhesive Bonding. Adhesive bonding uses bonding chemicals to stick two or more parts together. It can be used to join .

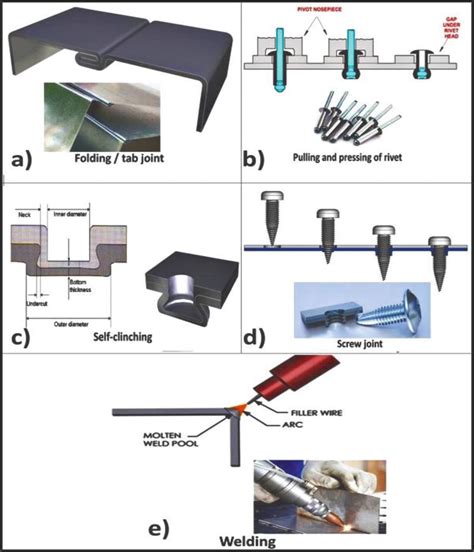

Because of the relatively clean finish, spot welding and arc welding using inert gas shielding are the preferred methods for sheet metal fabrication. Low temperature soldering for .Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. This article covers various types of sheet metal joining techniques, . In this blog post, we'll explore six main methods used in metal fabrication - welding, adhesive bonding, mechanical fastening, brazing, soldering, and riveting - along with their advantages and disadvantages.

Clinching, also known as press joining or press fastening, is a method that creates a mechanical interlock between two or more metal sheets. It involves pressing the sheets together with a die and punch, forming a .Mechanical joining methods, such as bolting, can provide an adaptable yet robust metal joining solution that is used in sectors including automotive, construction and heavy engineering. Mechanical joining is a simple method of securing two .

Low temperature soldering for delicate sheet metal structures. Soldering requires melting a lower temperature metal or alloy that flows into the gap between the sheets being joined, at temperatures up to 450C. For thin sheet materials it reduces the issue of distortion from welding, and can produce a very strong bond.. Soldering is a labor intensive method that . Metal Joining Processes - Download as a PDF or view online for free . • It is the economical way to join components in terms of material usage and fabrication costs. Other methods of assembly require, for example, drilling .• Joining includes welding, brazing, soldering, adhesive bonding of materials. • They produce permanent joint between the parts to be assembled. • They cannot be separated easily by application of forces. • They are mainly used to assemble many parts to make a system. • Welding is a metal joining process in which two or more parts are

temporary fixing examples for metal

Sheet metal joining is a crucial aspect of fabrication that can make or break the durability, functionality, and aesthetics of your projects. Whether you're working on prototypes or large-scale production, understanding various joining methods is key to creating strong, reliable connections.- permanent joining method usually used to join sheet and plates - rivets are metal fasteners that have a head and tail - two pieces to be joined are overlapped and drilled, rivet tail is inserted into hole, rivet head is then hammered over to squeeze two pieces together - used in handle of trowel Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. . Joining Methods. Depending on the design, you might need welds, rivets, or other joining methods. Their placement and type can significantly impact both the product's aesthetics and functionality. Riveting vs welding: this phrase not only represents two distinct methods of joining metals but also indicates a critical decision-making process in the field of manufacturing.The choice between riveting and welding can greatly impact the overall design, strength, cost, and functionality of the final product.. In the realm of sheet metal fabrication, at Worthy Hardware, .

From the solid-state bonding of friction stir welding to the precision of laser beam welding, the cool efficiency of cold metal transfer to the versatility of adhesive bonding, and the synergistic benefits of hybrid techniques, such methods are .Here, we will help answer which joining method is right for your enclosure by reviewing three techniques: Welding - joining one or more metal parts together using heat; Mechanical joining/mechanical fastening - joining metal using hardware or fasteners; Adhesive bonding - joining metals using adhesives such as epoxy or acrylic

Sheet Metal Joining Methods. Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and groove connections, adhesives, hemming, snap fits, clinching, tabs, and hinges.

Metal fabrication : a practical guide . Applied metallurgy -- Structural shapes and sizes -- Layout methods -- Shearing, bending, and rolling -- Drilling and thread cutting -- Joining -- Heating and cutting operations -- Annealing, hardening, and tempering -- Precision concepts and dimensions -- Shearing and bending -- Punching, notching, and . 1. Brazing: The Most Relevant Alternative to Welding. Compared with soldering, fastening, and other options for joining metal, welding and brazing are more effective when the joints are expected to be permanent and strong. Both methods are commercially viable, but they work differently.Although welding and metal fabrication are interconnected, they serve distinct purposes. Welding primarily focuses on joining metal parts together, while metal fabrication involves multiple processes to shape and assemble metal structures. In simpler terms, welding is a part of the broader metal fabrication process.

Sheet metal joining operation is crucial part of the sheet metal fabrication process. Joint reliability depends on its type, sheet metal material, and manufacturing process. . Following types of sheet metal joining techniques are available to . The sheet metal fabrication process involves several techniques that cut, form, or join metal into custom parts and components. Learn more! Get A Quote (613) 966-7551 . adhesives are the final method used to join metals .

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost . It is another reliable method used in metal fabrication to join pieces of sheet metal or other materials without melting them. Riveting in sheet metal involves inserting a rivet, a short metal pin, or a bolt through aligned holes in the pieces. Once in place, the protruding part of the rivet is deformed to create a head, holding the materials .

sheet metal joining techniques pdf

Consult Your Sheet Metal Fabricator about the Optimal Joining Method. ASM’s welders have decades of custom sheet metal fabrication experience and can work with you to determine the ideal joining method for your assembly—whether that means fabricating weld joints or using a different fastening method. Joint and weld solutions Of all welding methods, explosive welding provides the broadest range for joining dissimilar metals. It can fuse two metallurgically incompatible metals into various transitional joints. Explosive welding is commonly used for surface cladding of large flat plates and is an efficient method for manufacturing composite plates. 15. Friction WeldingThe process include cutting, bending, assembling. All the major productions include the fabrication process. Metal joining process are broadly classified into. Welding, soldering, brazing - The method of metal joining by heating of metal or filler metal above the melting point. .Methods of Joining. Here we will take a look at the main methods of materials joining; adhesives, mechanical fastening, and welding. 1. Adhesive Bonding. Adhesive bonding uses bonding chemicals to stick two or more parts together. It can be used to join polymers, metals and ceramics, either to themselves or each other.

Versatility in joining dissimilar metals; This method is particularly beneficial for applications requiring high-strength fastening points on sheet metal, such as in automotive body construction, shipbuilding, and structural steel fabrication. Introduction to Metal FabricationMetal fabrication is all about shaping and assembling metal parts into final products. Think of it as playing with building blocks, but instead of plastic, we're dealing with metal. There are many ways to do this, and each method offers its own advantages depending on what you're trying to build. At its core, fabrication involves . Fascinating advantages (e.g., lightweight and superior performances combined with ductility and strength) of metal-FRP (fiber reinforced polymer) hybrid components attract increasing attentions of engineers and scientists from aviation and automotive industries. Forming and joining are currently two main technical approaches to fabricate metal-FRP hybrid .

Understanding Fabrication Methods. The method that specifically joins together materials, particularly metals, is known as welding. Below are brief explanations of the options provided: Casting: This process involves pouring molten material into a mold to create a desired shape. It does not join materials, but rather forms them into a single item.Welding is a cost-effective solution as it does not require additional materials such as bolts, rivets, or adhesives, and it also does not require the additional labor for joining the parts. Overall, welding is a more efficient and reliable method for joining metal and thermoplastics than fabrication. Requires specialised equipment

1956 mercury sheet metal

1960s skates in metal box

Hey everyone, I've got 62!! 3/8" holes to weld up on my fenders,doors and quarterpanels after removing all the stainless trim. I recall seeing an article in Street Rodder a few years ago about a supplier for weld in mild steel plugs in a few common sizes. Any ideas on where I might find them?

methods of joining metals in fabrication|sheet metal joining screws