cnc machine advantages CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . Esprit Automation is a leading manufacturer of CNC flame & plasma cutting machines in the UK. From our base in Nottingham, we supply a range of advanced sheet and plate metal cutting solutions for customers throughout the world.

0 · disadvantages of cnc machines

1 · disadvantages of cnc

2 · cnc punching machine disadvantages

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · advantages of cnc milling machine

Comparing the electrical enclosures rating standards of NEMA and UL. Here’s a side-by-side look at the environmental ratings between the National Electrical Manufacturers Association and Underwriters Laboratories, Inc. for electrical enclosure types in non-hazardous locations. NEMA and UL are standards writing organizations.

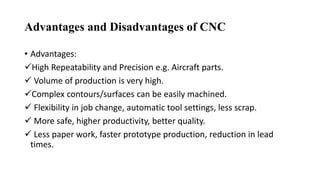

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an . What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and .In this article, we’ll explore CNC machining’s five biggest advantages, from its precision and efficiency to its cost-effectiveness and material versatility. 1. High Precision and Accuracy. One .

disadvantages of cnc machines

disadvantages of cnc

Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.CNC machining offers several significant advantages over traditional manufacturing methods. 1. High Precision and Accuracy. CNC machines utilize computer-controlled motion to ensure . Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex .

CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

CNC (Computer Numerical Control) machining is a subtractive manufacturing process used to produce parts and components made from materials like metals and . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

nema 4x stainless steel enclosures

cnc punching machine disadvantages

nelson metal fabrication show 2018

What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process. Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .In this article, we’ll explore CNC machining’s five biggest advantages, from its precision and efficiency to its cost-effectiveness and material versatility. 1. High Precision and Accuracy. One of the most significant advantages of CNC machining is its exceptional precision and accuracy. Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.

CNC machining offers several significant advantages over traditional manufacturing methods. 1. High Precision and Accuracy. CNC machines utilize computer-controlled motion to ensure incredibly tight tolerances. This level of precision is repeatable, making CNC machining ideal for high-volume production.

Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex processes. Disadvantages of CNC Machines: They require a high initial investment cost, need skilled operators for programming, and can be complex to maintain. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb. CNC (Computer Numerical Control) machining is a subtractive manufacturing process used to produce parts and components made from materials like metals and engineering plastics. Engineers select the appropriate tools for the job and load them along with the material into CNC machines.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry.It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. What are the primary advantages of CNC machining? CNC machining provides significant advantages, including unmatched precision and consistency, increased efficiency, the ability to create complex designs, and enhanced safety in the manufacturing process.

cnc milling pros and cons

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC technology is the .

In this article, we’ll explore CNC machining’s five biggest advantages, from its precision and efficiency to its cost-effectiveness and material versatility. 1. High Precision and Accuracy. One of the most significant advantages of CNC machining is its exceptional precision and accuracy.

Compared to manual machining, CNC technology improves efficiency and accuracy, makes production faster, and leads to safer and cheaper operations. As you might expect, there are disadvantages as well.

CNC machining offers several significant advantages over traditional manufacturing methods. 1. High Precision and Accuracy. CNC machines utilize computer-controlled motion to ensure incredibly tight tolerances. This level of precision is repeatable, making CNC machining ideal for high-volume production. Advantages of CNC Machines: They offer high precision and consistency, increased production speed, reduced labor costs, and the ability to automate complex processes. Disadvantages of CNC Machines: They require a high initial investment cost, need skilled operators for programming, and can be complex to maintain. CNC machines isolate machines from humans and mitigate the risk that crops up otherwise. These machines can function without an operator, thereby limiting the possibility of accidents and reducing the risk to life and limb.

nec grounding metal junction boxes

In today’s step-by-step guide, we will demonstrate how to select the right size panelboard (whether it’s a load center, distribution board, or circuit breaker panel) according to NEC and IEC standards, with worked examples. Related Post: How to .

cnc machine advantages|cnc milling pros and cons