how to calculate minimum bend radius of sheet metal Bend Radii & Minimum Bend Sizes. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values . Shop for Outdoor Lanterns in Decorative Outdoor Lighting. Buy products such as Better Homes & Gardens Metal Candle Holder Lantern, Black at Walmart and save.

0 · sheet metal bending radius chart

1 · sheet metal bending chart

2 · sheet metal bend radius formula

3 · sheet metal bend deduction chart

4 · minimum flange length sheet metal

5 · minimum bend radius formula

6 · bend allowance chart

7 · aluminum bend radius chart

RACO Handy Boxes- the ideal utility box for both new and old applications in ceilings or walls. This versatile box is specifically designed for convenience outlets, switch boxes, or small .

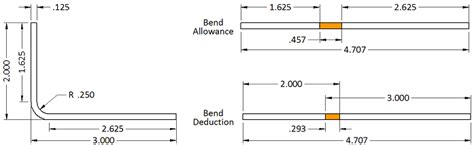

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend . You described a rough rule to find a steel’s minimum bend radius: Divide 50 by the material’s reduction percentage, as specified by the material supplier, subtract by 1, and then multiply by the plate thickness. Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for .

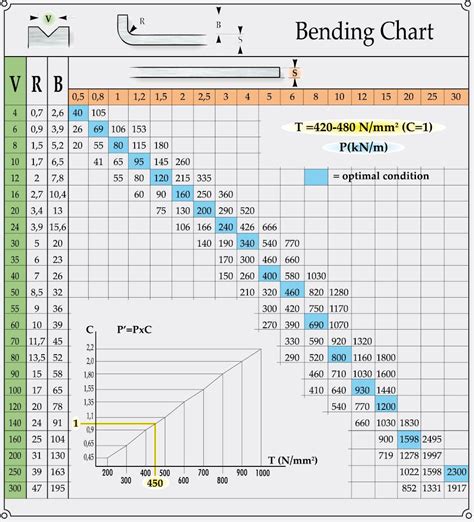

Bend Radii & Minimum Bend Sizes. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. Use this document to choose values . Choose the right bend radius for the material and thickness of the sheet metal. Use proper bending techniques, such as air bending or bottom bending, depending on the desired bend angle. Consider the tooling . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange. You just have to insert the characteristics of the sheet metal to be bent. The tool can calculate .

In this Tech Tip, we will explore the various bend calculation options available for sheet metal, namely K Factor, bend allowance, and bend deduction, and guide you on when to use each.Minimum bend radius calculations TB By Tyler Bennett 06/23/15 Does anybody know of a relatively simple way to calculate a minimum bend radius for a given thickness of sheet metal?Determining the Minimum Internal Radius for a Bend in Sheet Metal. There are a two major factors that affect how tight you can make the internal radius of a bend in a piece of sheet metal: . Steve Benson, the President of ASMA LLC, .

For a sheet metal stock with inch thickness, determine the minimum tool radius for both the steel and aluminum alloys that will not tear the material. Assume the sheet of material is in pure bending (i.e., no additional tension is . It provides a comprehensive listing of key parameters such as material thickness, bending radius, bending angle, bend allowance, and bend deduction values for common materials. This information is crucial for accurately calculating the development length of a sheet metal part after bending. Further reading: Bend Deduction Calculator Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.)

So, for a 1.0 mm thick aluminum sheet bent at 90°, the minimum bend radius should be 1.5 mm. Steel (1.5 mm thick, 90° bend) For steel, a k factor of 2.0 is often used. Applying this: . Die Selection: When bending sheet metal, the die radius should be at least equal to the calculated bend radius to avoid material damage. As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification.Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for larger bend radii. The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness.

sheet metal bending radius chart

Bending radius is often used in sheet metal working. This page explains the working methods, measurement problems, and how to measure 3D shapes accurately. . However, the minimum bending radius varies depending on the material, sheet thickness, die, and other factors, making it difficult to calculate the correct value using a mathematical . Factors Influencing the Minimum Bend Radius. The minimum bend radius of the sheet metal is affected by several factors, each of which is of specific importance in determining the most desirable degree of bend that would prevent collapse or paper deformation. tAng factors include:. Material Type: Different materials have varying levels of ductility and tensile strength, . The minimum bend distance for sheet metal is generally around 1.5 to 2 times the material thickness. However, it can vary depending on the material and specific application. What is the minimum radius for sheet metal? The minimum bend radius for sheet metal is typically around 0.5 to 1.5 times the material thickness, but it varies based on the . This second form of minimum bend radius is therefore defined as the “minimum bend radius for a material thickness.” This is usually expressed in terms of multiples of the material thickness—2Mt, 3Mt, 4Mt, etc. Material suppliers offer minimum bend radius charts that define minimum radii for various alloys and tempers of those alloys.

When the bending radius is large and the bending angle is small, the degree of deformation is low and the neutral layer is close to the center of the sheet thickness.. However, when the bending radius (R) becomes smaller and .

If you are working with a material thickness of 0.100 in., multiply that by 0.63 to get a minimum inside bend radius of 0.063 in. For this material, this is the minimum producible inside radius with air forming. . Steve Benson .

Welcome to Kreatorzone! On this sheet metal design series you will find the recommended common sheet metal design guidelines in Sheet metal Minimum Bend Radi.Bending Radius Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective design work it is recommended to speak with manufacturers so that design can be done around their standard operating procedures as well as available tooling.

Table of Contents. 1 Common Bend Radius Design Mistakes; 2 Sheet Metal Part Design for Manufacturing Tip. 2.0.1 UNABLE TO UNFOLD PART, SHEET METAL BEND RADIUS ISSUE RESOLVED; 3 How to implement the industry standard sheet metal bend radius. 3.1; 3.2 Your Partner in Precision Sheet Metal Design; 4 Sheet Metal Part Design for Manufacturing . The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness.

Subscribe Now:http://www.youtube.com/subscription_center?add_user=ehoweducationWatch More:http://www.youtube.com/ehoweducationA composite laminate is a .

Table.No.2.Sheet Metal Bend Radius Chart. “t” describes thickness of object in Table.No.2. From Table.No.2 it is prominent that minimum bend sheet metal radius for any metallic job is approximately three times of its thickness, otherwise metallurgical defect will .

The minimum recommended sheet metal flange bend length avoid cracks in the bending area. It shall be equal to three times of sheet thickness plus bend radius. Minimum Sheet Metal Flange Bend Length = 3 x Sheet Thickness + Bend RadiusThe drawing calls out a radius for all bends however for flat, flange, and bends the tools all create a default radius. I can go find the default minimum in model properties, but it's locked and I can not figure out how to unlock it. I need the radius to be a specific value to create an accurate part. How can I accomplish thisThe thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if they just have the bend deduction values for you. Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out.

Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the radius is less than recommended, this can cause material flow problems in soft material and fracturing in hard material. Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part.

metal rolling tool box plans

sheet metal bending chart

$26.70

how to calculate minimum bend radius of sheet metal|minimum flange length sheet metal