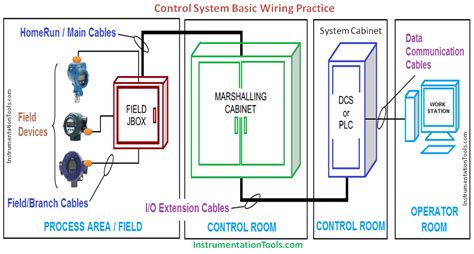

electrical marshalling box In simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules. Typically used on aluminum parts over 0.40” thick, open corner joints can be welded using several methods: fillet/seam, fuse, tack, or stitch .

0 · marshalling panel vs junction box

1 · marshalling panel system

2 · marshalling panel box

3 · marshalling control panel

4 · marshalling cabinet wiring

5 · marshalling cabinet box

6 · marshalling box vs junction box

7 · cross wire marshalling cabinet

Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc for clean, high-quality welds. Features like AC/DC capability and dual voltage input add versatility. The Hobart Handler 140 MIG Welder is my top choice because of its versatility and user friendly interface.

Marshalling is usually carried out in one of three ways: cross-wire, fan-out and half-knit. As discussed in the Typical Instrumentation Architecture .

A marshalling cabinet allows the field wiring to be organized and protected, and it makes it easier to troubleshoot and maintain the system. A marshalling cabinet typically contains a series of terminal blocks or connectors that are used to terminate the field wiring. Marshalling is usually carried out in one of three ways: cross-wire, fan-out and half-knit. As discussed in the Typical Instrumentation Architecture and Automation System, the automation architecture of the plant has a marshalling cabinet between the junction box and the system cabinet.In simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules.

A marshalling cabinet is a type of electrical enclosure that is used to organize and terminate field wiring in an industrial control system. It typically contains a series of terminal blocks or connectors that are used to connect field wiring to the control system.

A marshalling cabinet is an electrical enclosure. It is specifically designed to terminate or organize a field wiring. This is commonly found in industrial process control. Marshaling kiosks provide convenient connection points for control, protection, and instrumentation systems which are used in substations. This includes DC and AC power, instrument transformers, and switchgear equipment. In this article, we will learn more about a marshalling cabinet, review a typical layout, and compare it versus a junction box. In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments.

The marshalling cabinet or field marshalling panel acts as an interface between the system cabinet of DCS and the field junction boxes. The main cables from the field junction boxes are laid to the marshalling cabinet.Electronic Marshalling is an innovative design for connecting field devices to a DeltaVTM Process Automation System. This document provides a detailed overview of what Electronic Marshalling is, as well as describes the benefits that it provides.

The technology of the I/O marshalling system – classic signal marshalling and Universal I/O systems in comparison. Compare both products now.

A marshalling cabinet allows the field wiring to be organized and protected, and it makes it easier to troubleshoot and maintain the system. A marshalling cabinet typically contains a series of terminal blocks or connectors that are used to terminate the field wiring. Marshalling is usually carried out in one of three ways: cross-wire, fan-out and half-knit. As discussed in the Typical Instrumentation Architecture and Automation System, the automation architecture of the plant has a marshalling cabinet between the junction box and the system cabinet.In simple terms, Marshalling cabinets are located between junction boxes and control system. Within the marshalling cabinets, field cables are connected and cross-wiring is performed to order the signals according to the I/O modules. A marshalling cabinet is a type of electrical enclosure that is used to organize and terminate field wiring in an industrial control system. It typically contains a series of terminal blocks or connectors that are used to connect field wiring to the control system.

A marshalling cabinet is an electrical enclosure. It is specifically designed to terminate or organize a field wiring. This is commonly found in industrial process control.

marshalling panel vs junction box

Marshaling kiosks provide convenient connection points for control, protection, and instrumentation systems which are used in substations. This includes DC and AC power, instrument transformers, and switchgear equipment.

In this article, we will learn more about a marshalling cabinet, review a typical layout, and compare it versus a junction box. In industrial applications, a marshalling cabinet provides an interface between a control system (DCS/PLC) and the field instruments.The marshalling cabinet or field marshalling panel acts as an interface between the system cabinet of DCS and the field junction boxes. The main cables from the field junction boxes are laid to the marshalling cabinet.Electronic Marshalling is an innovative design for connecting field devices to a DeltaVTM Process Automation System. This document provides a detailed overview of what Electronic Marshalling is, as well as describes the benefits that it provides.

marshalling panel system

The main things to consider when choosing your equipment when working with pure carbon dioxide welding gas are the correct CO2 gas, a good MIG welder, a proper welding gas regulator, and the necessary MIG consumables.

electrical marshalling box|marshalling control panel