asme sheet metal standards Explore ASME’s latest editions of the Y14 design standards. Gain key guidance . On this episode of Make It Kustom, I continue to repair the rust on the GMC G10 boogie van. We talk in depth about technique for repairing rust and welding o.

0 · list of ASME standards pdf

1 · free download ASME standards

2 · ASME standards list

3 · ASME standards collection

4 · ASME standard code list

5 · ASME specifications list

6 · ASME material standards pdf

7 · ASME code chart

General Inquiry for all 3 Companies: Wellington Plumbing & Heating Ltd. .

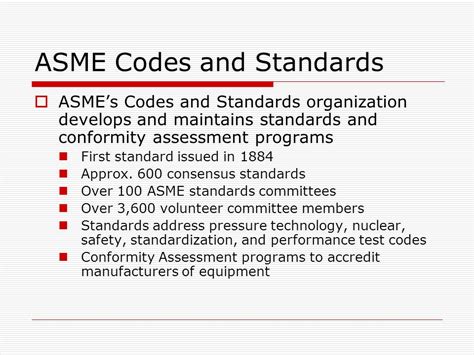

Find the Standard that applies to your industry and helps you promote safety, reliability, productivity, and efficiency, as it pertains to engineering components or equipment. This page provides a list of all ASME codes & standards including the industry famous B31.3, BPVC, .

Explore ASME’s latest editions of the Y14 design standards. Gain key guidance .ASME Y14.5 is the authoritative guideline for the design language of Geometric .Explore ASME’s latest editions of the Y14 design standards. Gain key guidance across product design with essential tools, templates, design rules & requirements.

ASME Y14.5 is the authoritative guideline for the design language of Geometric Dimensioning and Tolerancing.

The basis for this standard will be the ASME Drawing Standards Manual, MIL-STD-100, previous ASA and ANSI standards, pertinent international and military standards . Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to . However, for flexible sheet metal assemblies, the traditional methods are not adequate: the components can deform, changing the dimensions during assembly. This paper .

Some of the new provisions of the 2010 edition changes to the ASME Boiler and Pressure Vessel Code, Section IX Welding and Brazing Qualifications, to be implemented on January 1, 2011, are.Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of .

List of ASTM / ASME Metal Sheet Product Specs, Datasheets, Manufacturers & Suppliers

Find the Standard that applies to your industry and helps you promote safety, reliability, productivity, and efficiency, as it pertains to engineering components or equipment. This page provides a list of all ASME codes & standards including the .Explore ASME’s latest editions of the Y14 design standards. Gain key guidance across product design with essential tools, templates, design rules & requirements.ASME Y14.5 is the authoritative guideline for the design language of Geometric Dimensioning and Tolerancing. ASME Y14.5 is an established, widely used GD&T standard containing all the necessary information for a comprehensive GD&T system. The ASME Y14.5 standard establishes symbols, definitions, and rules for geometric dimensioning and tolerancing.

The basis for this standard will be the ASME Drawing Standards Manual, MIL-STD-100, previous ASA and ANSI standards, pertinent international and military standards and specifications, and standards already established and in .

list of ASME standards pdf

Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection.

However, for flexible sheet metal assemblies, the traditional methods are not adequate: the components can deform, changing the dimensions during assembly. This paper evaluates the effects of deformation on component tolerances using linear mechanics. Some of the new provisions of the 2010 edition changes to the ASME Boiler and Pressure Vessel Code, Section IX Welding and Brazing Qualifications, to be implemented on January 1, 2011, are.Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of the features are shown below, they are listed from least to most expensive (tooling cost not included).

List of ASTM / ASME Metal Sheet Product Specs, Datasheets, Manufacturers & Suppliers

Find the Standard that applies to your industry and helps you promote safety, reliability, productivity, and efficiency, as it pertains to engineering components or equipment. This page provides a list of all ASME codes & standards including the .Explore ASME’s latest editions of the Y14 design standards. Gain key guidance across product design with essential tools, templates, design rules & requirements.ASME Y14.5 is the authoritative guideline for the design language of Geometric Dimensioning and Tolerancing. ASME Y14.5 is an established, widely used GD&T standard containing all the necessary information for a comprehensive GD&T system. The ASME Y14.5 standard establishes symbols, definitions, and rules for geometric dimensioning and tolerancing.

The basis for this standard will be the ASME Drawing Standards Manual, MIL-STD-100, previous ASA and ANSI standards, pertinent international and military standards and specifications, and standards already established and in . Formed sheet metal parts must be fully defined as a finished good in the completed (folded) state per section; however, sheet metal parts also require specific data to be shown on the drawing to ensure proper manufacturing and inspection. However, for flexible sheet metal assemblies, the traditional methods are not adequate: the components can deform, changing the dimensions during assembly. This paper evaluates the effects of deformation on component tolerances using linear mechanics.

Some of the new provisions of the 2010 edition changes to the ASME Boiler and Pressure Vessel Code, Section IX Welding and Brazing Qualifications, to be implemented on January 1, 2011, are.Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of the features are shown below, they are listed from least to most expensive (tooling cost not included).

free download ASME standards

Cut your new panel the way you want it, lay it up an draw around it, and then cut the truck out about 1/2 in smaller or whatever your flange width is. Then go around the truck metal with the flange tool and then lay the new panel in and check the fit.

asme sheet metal standards|ASME code chart