basic of cnc machine pdf What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the . Gas metal arc welding, also known as Metal-Inert Gas (MIG) welding, is a versatile semi-automatic welding technique particularly suited for the welding of thinner materials (<1/2 [13 mm] thick). Welding speeds for GMAW are typically slower for galvanized surfaces.

0 · types of cnc machines PDF

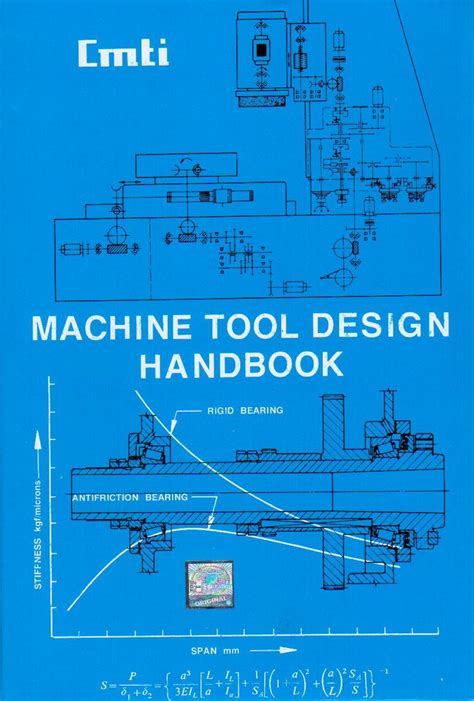

1 · cnc machine tool design PDF

2 · cnc machine manual PDF

3 · cnc machine drawing PDF

4 · cnc machine codes list PDF

5 · cnc machine books free download PDF

6 · cnc machine basic knowledge PDF

7 · cnc machine PDF download

Oak Ridge Waste and Recycling in Danbury, CT is looking for a Welder / .

types of cnc machines PDF

what gauge is 1 8 sheet metal

cnc machine tool design PDF

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsTo maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written .

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC .Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can .

than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. Increase in electrical maintenance, high initial .iv 2. Implementation of Switching Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 2.1 Tool .

what does cnc manufacturing mean

In this chapter, we will explore the most common types of CNC machines, including milling machines, turning machines, plasma cutting machines, laser cutting machines, and routing .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials likeWhat is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motors

To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supportedTypes of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-type

Computer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,

than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. Increase in electrical maintenance, high initial investment and high per hour operating costs than the traditional systems. Fewer workers are required to operate CNC machines compared to manually operated

iv 2. Implementation of Switching Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 2.1 Tool .

In this chapter, we will explore the most common types of CNC machines, including milling machines, turning machines, plasma cutting machines, laser cutting machines, and routing machines. We will discuss their working principles, use cases, and the advantages they offer.

This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials likeWhat is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.CNC Motion Control • Machine locates axes from programmed commands • Components: drive screws, CNC guideways, servo motorsTo maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

Types of CNC Milling Machines • Two classes of machining centers: • Vertical spindle and horizontal spindle • Types of milling machines: vertical and horizontal machining centers (VMC and HMC) • ATC types: carousel-type and swing-arm-typeComputer Numerical Control (CNC) is one in which the functions and motions of a machine tool are controlled by means of a prepared program containing coded alphanumeric data. CNC can control the motions of the work piece or tool, the input parameters such as feed,than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. Increase in electrical maintenance, high initial investment and high per hour operating costs than the traditional systems. Fewer workers are required to operate CNC machines compared to manually operated

iv 2. Implementation of Switching Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61 2.1 Tool .

A Fabricator resume summary should showcase a candidate’s ability to fabricate metal, wood, or plastic parts and components. The summary should also highlight their knowledge of .

basic of cnc machine pdf|cnc machine codes list PDF