cnc machine offset pdf Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has . Explore the different types of machining processes, from conventional methods like turning, milling, and drilling to non-conventional techniques such as EDM and chemical machining. Learn how each process is used to shape materials, create intricate designs, and work with hard-to-machine substances.

0 · what is wear offset

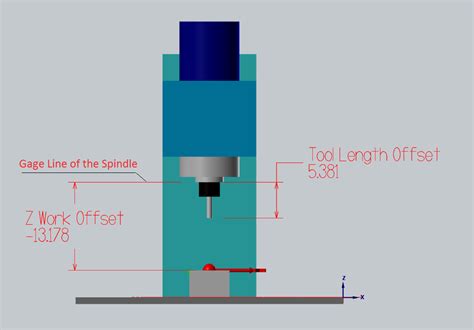

1 · what is tool length offset

2 · offset turning on cnc lathe

3 · offset meaning in cnc programming

4 · offset in cnc lathe

5 · geometry vs wear offsets

6 · cnc work offsets

7 · cnc tool offsets explained

This white paper explores the key components of sheet metal fabrication, ranging from the processes to materials, finishes, design tips, and more.

A typical milling geometry offset page on the machine display screen. These numbers reflect the tool length from gage line to the tool tip in its original and unworn state.

This course emphasizes anapproach to CNC machining referred to as ubtractive .To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has .This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional .

This manual provides basic programming principles necessary to begin program- ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is .

what is wear offset

what is tool length offset

What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the .table of contents 1 - numerical control 1 definition of numerical control . . . 1 nc and cnc technology ... 1 conventional and cnc machining. . . 2 This paper presents the development of a Global Offset compensation method utilizing the measurements of machined part (s). The Global Offset for a machine tool is estimated through a model.A typical milling geometry offset page on the machine display screen. These numbers reflect the tool length from gage line to the tool tip in its original and unworn state.

To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials like

This manual provides basic programming principles necessary to begin program- ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

offset turning on cnc lathe

table of contents 1 - numerical control 1 definition of numerical control . . . 1 nc and cnc technology ... 1 conventional and cnc machining. . . 2 This paper presents the development of a Global Offset compensation method utilizing the measurements of machined part (s). The Global Offset for a machine tool is estimated through a model.

Modern CNC Machine Characteristics ØMassive, usually four times heavier than an equivalent conventional (manual) machine. ØLarge motors with high speed capabilities to take advantage of modern cutting tools. Horsepower and spindle speeds are generally four to ten times faster than conventional machines. Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for.A typical milling geometry offset page on the machine display screen. These numbers reflect the tool length from gage line to the tool tip in its original and unworn state.To maximize learning, this course focuses on CNC machines made by Haas Automation, Inc. of Oxnard, CA. Chapters 5 (CNC Programming Language) and 6 (CNC Operation) are written specifically.

cnc stamping die suppliers

Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.This course emphasizes anapproach to CNC machining referred to as ubtractive RapidS Prototyping (SRP). SRP deals with small quantities of functional prototypes. Functional prototypes are made from materials likeThis manual provides basic programming principles necessary to begin program- ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.What is a CNC Milling Machine? A CNC Milling machine is a computer controlled machine that can be used to make very precise parts. The machine works by removing material from the workpiece with a rotating cutting tool.

table of contents 1 - numerical control 1 definition of numerical control . . . 1 nc and cnc technology ... 1 conventional and cnc machining. . . 2 This paper presents the development of a Global Offset compensation method utilizing the measurements of machined part (s). The Global Offset for a machine tool is estimated through a model.Modern CNC Machine Characteristics ØMassive, usually four times heavier than an equivalent conventional (manual) machine. ØLarge motors with high speed capabilities to take advantage of modern cutting tools. Horsepower and spindle speeds are generally four to ten times faster than conventional machines.

offset meaning in cnc programming

Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

cnc machine offset pdf|what is tool length offset