3 axis cnc milling machine wiki Multiaxis CNC machines are used in many industries including:• Aerospace industry: Multiaxis machines are used in the . See more STAGGERING WEIGHT CAPACITY - Urrea's metal toolbox has the ability to carry loads of up to 64 pounds, making it a reliable choice for hauling to and from jobsites. FLEXIBLE OPENING - With a 100 degree opening, this toolbox allows the tradesman to easily pivot in and out of its interior while working in tight spaces.Choose from over 1,500 metal urns for ashes from Memorials.com. We have gold, silver, brass & stainless steel cremation urns and all with free shipping.

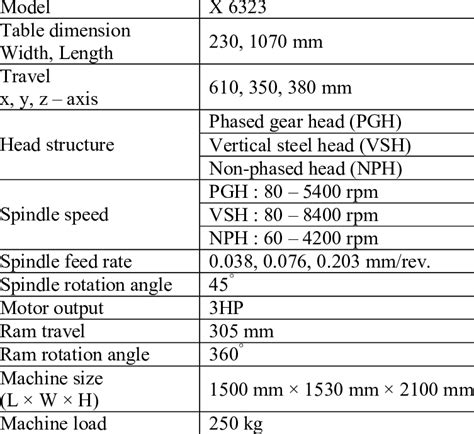

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

$283K+

There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored. See more

Multiaxis machining is a manufacturing process that involves tools that move in 4 or more directions and are used to manufacture parts out of metal or other materials by milling away excess material, by See moreMultiaxis CNC machines are used in many industries including:• Aerospace industry: Multiaxis machines are used in the . See more

• Machine tool• Milling machine• Numerical control• CNC pocket milling See more

CAM software automates the process of converting 3D models into tool paths, the route the multiaxis machine takes to mill a part (Fig. 1). This software takes into account the different . See moreCNC routers come in many configurations, from small home-style D.I.Y. "desktop", to large industrial routers manufactured for commercial use. CNC routers are used in sign shops, cabinet making, aerospace and boat-making. Although there are many configurations, most CNC routers have a few specific parts: a dedicated CNC controller, one or more spindle motors, servo motors or stepper motors, servo amplifiers, A. A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by .

3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z .There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.CNC routers are typically available in 3-axis and 5-axis CNC formats. Many manufacturers offer A and B axis for full 5-axis capabilities and rotary 4th axis. Common industrial CNC router sizes include 4 × 8 feet and 5 × 10 feet.

A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece. This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes. Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes.3-axis machines are ideal for simple tasks that don’t require intricate detailing or depth. As such, it is one of the most preferred techniques for creating mechanical parts for automation. Additionally, you can also use it for cutting sharp edges, boring, milling slots, tapping, and drilling holes.

CNC milling machine is an automatic machining equipment developed on the basis of general milling machines. The machining technology of the two is basically the same, and the structure is somewhat similar. CNC milling machines are divided into two categories: without tool magazine and with tool magazine. Among these options, 3-axis CNC, 4-axis CNC, and 5-axis CNC machining are the most common options. Professionals often wonder about the best choice between 3 vs 4 vs 5-axis CNC machining. This article will discuss in detail the .

specifications of cnc milling machine

What is a 3-axis CNC Milling Machine? A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth. Multi-access milling and machining align the tool with your material and then works it down to your desired size and shape. The typical configuration moves the device while keeping your part stationary. The tool moves along three axes: X, Y, and Z, or width, length, and depth.There are three main components to multiaxis machines: The machines physical capabilities i.e. torque, spindle speed, axis orientation/operation. The CNC drive system, the components that move the machine. This includes servo-motors, rapid traverse systems, ball screws, and how positioning is monitored.CNC routers are typically available in 3-axis and 5-axis CNC formats. Many manufacturers offer A and B axis for full 5-axis capabilities and rotary 4th axis. Common industrial CNC router sizes include 4 × 8 feet and 5 × 10 feet.

metal shower enclosure grounding requirement

A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece. This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] 3-axis CNC (computer numerical control) machining is a manufacturing process that uses a computer-controlled cutting tool to remove material from a workpiece. The cutting tool moves in three axes – X, Y, and Z – to create precise cuts and shapes.

Most CNC machines are either 3- or 5-axis, and, in this article, we’ll look at their differences and what they’re each good for. A 3-axis CNC machine, such as a lathe, mill, or machine tool center, moves its tool (whether it’s a cutter, drill, or mill) along the X (left to right), Y (front to back), and Z (up and down) axes.

metal siding on house pics

small 3 axis cnc mill

3-axis machines are ideal for simple tasks that don’t require intricate detailing or depth. As such, it is one of the most preferred techniques for creating mechanical parts for automation. Additionally, you can also use it for cutting sharp edges, boring, milling slots, tapping, and drilling holes.CNC milling machine is an automatic machining equipment developed on the basis of general milling machines. The machining technology of the two is basically the same, and the structure is somewhat similar. CNC milling machines are divided into two categories: without tool magazine and with tool magazine. Among these options, 3-axis CNC, 4-axis CNC, and 5-axis CNC machining are the most common options. Professionals often wonder about the best choice between 3 vs 4 vs 5-axis CNC machining. This article will discuss in detail the .

What is a 3-axis CNC Milling Machine? A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth.

datron cnc price list

This Sanoxy USB sharing switch is to share a USB device like printer, scanner, HDD storage, etc for two computers via USB connections. And you can shift via hot key (Ctrl+F11) from one computer to another to use the external USB devices. It’s USB powered and no external power adapter is needed.

3 axis cnc milling machine wiki|3 axis cnc machine price