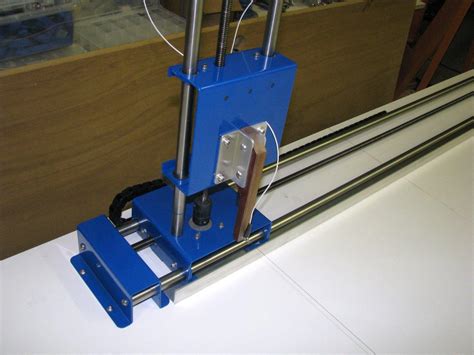

cnc foam cutting machine plans In this tutorial we will learn how to build an Arduino CNC foam cutting machine. This is a typical DIY CNC machine because it’s made out of simple and cheap materials, some 3D printed parts and it . Waterproof IP68 Connector: IP68 high-level waterproof class, moisture-proof, dust-proof, anti-UV. 2 Way Plastic Terminal, it can be installed horizontal and vertical as an external .

0 · wholesale cnc router foam cutting

1 · how to cut foam precisely

2 · hobby cnc foam cutter

3 · cnc foam cutting near me

4 · cnc foam cutting machine supplier

5 · best cnc foam cutter factories

6 · 5 axis cnc foam cutter

7 · 4 axis cnc foam cutter

We carry Type A, Type B and Type AB Self Tapping Screws, also known as Self Tapping Sheet Metal Screws (SMS), in a variety of drives, head styles, sizes and materials.

In this tutorial we will learn how to build an Arduino CNC foam cutting machine. This is a typical DIY CNC machine because it’s made out of simple and cheap materials, some 3D printed parts and it .A CNC Hot-wire cutter is an awesome tool to have when you are building aeroplanes out of foam. It allows the ability to cut out any aerofoil shape from a CAD design accurately. A properly .Most types of foam can be cut with a hot wire and if you can control the wire accurately then you can make wings and fuselages for RC aeroplanes and .Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics. Build Complete! This is a new build of a USB version of CNC hot wire foam cutter using 3d printer electronics? The .

The build of the CNC hot wire foam cutting machine isn’t difficult just measure twice and cut once as the saying goes. This page has the build instructions, plans and main parts you’ll need as . for 5 PCBs (Any Color): https://jlcpcb.comCode, 3D model, parts list and more details https://howtomechatronics.com/projects/arduino-cnc-foam-cutting-ma.

Make a CNC Hot Wire Foam Cutter from parts available at your local hardware store like HomeDepot . This machine can be used to cut wings for RC planes, surfboards, crown molding, packaging foam and lots more. Polystyrene (EPS .As you upgrade your making capabilities, you might find that precisely cutting foam — perhaps for model airplane wings — would be a great ability to have. If so, then be sure to check out the video below by Michael Rechtin, who made . For a little money and a large investment in time, you can build your own CNC foam cutter. It takes about a half an hour to prepare a set of plans for cutting and about 15 minutes per sheet to cut them out.In this tutorial we will learn how to build an Arduino CNC foam cutting machine. This is a typical DIY CNC machine because it’s made out of simple and cheap materials, some 3D printed parts and it has an Arduino as a controller. You can watch .

A CNC Hot-wire cutter is an awesome tool to have when you are building aeroplanes out of foam. It allows the ability to cut out any aerofoil shape from a CAD design accurately. A properly configured machine can save you a lot of effort and produce a smooth finish.Most types of foam can be cut with a hot wire and if you can control the wire accurately then you can make wings and fuselages for RC aeroplanes and many other things e.g. signs. It’s possible to do without a CNC (Computer Numerical Control) machine just by guiding a .Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics. Build Complete! This is a new build of a USB version of CNC hot wire foam cutter using 3d printer electronics? The picture below shows my latest RC models I’ve built with .The build of the CNC hot wire foam cutting machine isn’t difficult just measure twice and cut once as the saying goes. This page has the build instructions, plans and main parts you’ll need as well as the cutting lists.

for 5 PCBs (Any Color): https://jlcpcb.comCode, 3D model, parts list and more details https://howtomechatronics.com/projects/arduino-cnc-foam-cutting-ma.

wholesale cnc router foam cutting

how to cut foam precisely

Make a CNC Hot Wire Foam Cutter from parts available at your local hardware store like HomeDepot . This machine can be used to cut wings for RC planes, surfboards, crown molding, packaging foam and lots more. Polystyrene (EPS and XPS) will cut using a hot wire - other foams - like polyurethane should only be cut with a blade or saw.As you upgrade your making capabilities, you might find that precisely cutting foam — perhaps for model airplane wings — would be a great ability to have. If so, then be sure to check out the video below by Michael Rechtin, who made a four-axis CNC cutter using readily available and .

In this blog post, we will explore how to design and build a DIY CNC foam cutting machine using inexpensive components and open-source software. To start, we need to choose the right components for our machine.

For a little money and a large investment in time, you can build your own CNC foam cutter. It takes about a half an hour to prepare a set of plans for cutting and about 15 minutes per sheet to cut them out.In this tutorial we will learn how to build an Arduino CNC foam cutting machine. This is a typical DIY CNC machine because it’s made out of simple and cheap materials, some 3D printed parts and it has an Arduino as a controller. You can watch .A CNC Hot-wire cutter is an awesome tool to have when you are building aeroplanes out of foam. It allows the ability to cut out any aerofoil shape from a CAD design accurately. A properly configured machine can save you a lot of effort and produce a smooth finish.

Most types of foam can be cut with a hot wire and if you can control the wire accurately then you can make wings and fuselages for RC aeroplanes and many other things e.g. signs. It’s possible to do without a CNC (Computer Numerical Control) machine just by guiding a .Build a Hot Wire CNC Foam Cutter with inexpensive 3d printer electronics. Build Complete! This is a new build of a USB version of CNC hot wire foam cutter using 3d printer electronics? The picture below shows my latest RC models I’ve built with .The build of the CNC hot wire foam cutting machine isn’t difficult just measure twice and cut once as the saying goes. This page has the build instructions, plans and main parts you’ll need as well as the cutting lists.

for 5 PCBs (Any Color): https://jlcpcb.comCode, 3D model, parts list and more details https://howtomechatronics.com/projects/arduino-cnc-foam-cutting-ma.Make a CNC Hot Wire Foam Cutter from parts available at your local hardware store like HomeDepot . This machine can be used to cut wings for RC planes, surfboards, crown molding, packaging foam and lots more. Polystyrene (EPS and XPS) will cut using a hot wire - other foams - like polyurethane should only be cut with a blade or saw.As you upgrade your making capabilities, you might find that precisely cutting foam — perhaps for model airplane wings — would be a great ability to have. If so, then be sure to check out the video below by Michael Rechtin, who made a four-axis CNC cutter using readily available and .

hobby cnc foam cutter

what tool is best to remove screws from junction boxes

INSTRUCTIONS: Click on the MicroStation (DGN) filename to download. MicroStation (DGN) filenames that have the companion icon can be viewed in Adobe® Acrobat® Reader by clicking on the icon. Gray - Indicates that standard sheets will be removed soon. Yellow - The most recent changes or new standard sheets. Typ. Std. Fwy. Pvmt. Mks. - w/Raised Pvmt.

cnc foam cutting machine plans|hobby cnc foam cutter