common sheet metal parts Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum . Are you considering a farmhouse sink? Torn between a stainless steel farmhouse style kitchen sink and a classic white one? Here are several stunning kitchens with beautiful stainless steel farmhouse style kitchen sinks.

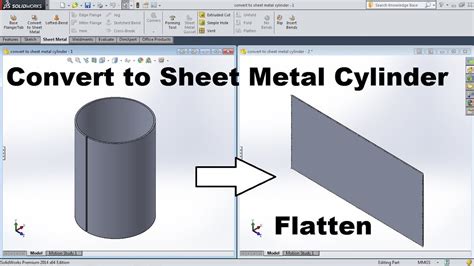

0 · solidworks convert to sheet metal

1 · sheet metal parts near me

2 · sheet metal dimensioning standards

3 · automotive sheet metal near me

4 · aftermarket sheet metal parts

5 · aftermarket sheet metal car parts

6 · aftermarket sheet metal body parts

7 · aftermarket auto sheet metal parts

Under every ICON™ roller cabinet, three 14-gauge U channels distribute weight evenly to the industry-leading 2,000-pound-rated suspension casters with easy locks, so these boxes glide into place easily and stay in place securely.

Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum .

ford 1998 e350 smart junction box

Learn about the critical factors to consider when selecting a material for your sheet metal parts: types, application, physical properties, finishing, and cost.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with . Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This article will explore in detail what materials can be formed into sheet metal, sheet metal .

Learn about the six imperative materials used in sheet metal fabrication. Discover their properties, applications and importance in the manufacturing process. Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum advantages: Lightweight: Great for applications where weight reduction is key, such as in automotive and aerospace industries. Learn about the critical factors to consider when selecting a material for your sheet metal parts: types, application, physical properties, finishing, and cost.

Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting.

Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal part-forming processes, and their applications.

Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project. Whether you’re a seasoned professional or new to the world of metalworking, this guide will equip you with the tools to create flawless metal parts.

There is a wide range of alloys and metals which come in sheet form and that are used in manufacturing and fabrication. Which material is used depends on a number of factors. These factors include weldability, formability, strength, weight, cost and the corrosion resistance of the material. The more common sheet metals used in fabrication are:Sheet metal parts are known for their durability, which makes them great for end use applications (e.g. chassis). Parts used for low volume prototypes, and high volume production runs are most cost-effective due to large initial setup and material costs. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

The Sheet metal material selection during product design impact the sheet metal part design, manufacturing process, cost, and part performance. In this article, we will discuss sheet metal materials, their advantages, and their limitations. Learn about the six imperative materials used in sheet metal fabrication. Discover their properties, applications and importance in the manufacturing process.

Let’s dive into the 8 most common sheet metals you’ll find in metal fabrication shops, exploring their unique advantages, disadvantages, and typical applications. Aluminum advantages: Lightweight: Great for applications where weight reduction is key, such as in automotive and aerospace industries. Learn about the critical factors to consider when selecting a material for your sheet metal parts: types, application, physical properties, finishing, and cost.Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. Many processes are utilized to form parts from sheet metal, including laser cutting, plasma cutting, and sheet metal bending. This article will explore in detail what materials can be formed into sheet metal, sheet metal geometries, the most common sheet metal part-forming processes, and their applications.

Discover the key fundamentals of this technique and gain the knowledge you need to make informed decisions for your project. Whether you’re a seasoned professional or new to the world of metalworking, this guide will equip you with the tools to create flawless metal parts.

There is a wide range of alloys and metals which come in sheet form and that are used in manufacturing and fabrication. Which material is used depends on a number of factors. These factors include weldability, formability, strength, weight, cost and the corrosion resistance of the material. The more common sheet metals used in fabrication are:

solidworks convert to sheet metal

Sheet metal parts are known for their durability, which makes them great for end use applications (e.g. chassis). Parts used for low volume prototypes, and high volume production runs are most cost-effective due to large initial setup and material costs. In this article, we will provide a comprehensive guide to sheet metal fabrication design, including tips for material selection, geometric constraints, and cost-effective design strategies.

sheet metal parts near me

Example of a beach style green two-story mixed siding house exterior design in Jacksonville with a hip roof, a metal roof and a white roof

common sheet metal parts|aftermarket sheet metal car parts