cnc machining choosing inserts There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining . $14.19

0 · what is a cnc insert

1 · types of machining inserts

2 · types of cutting inserts

3 · types of cnc inserts

4 · how to choose a turning insert

5 · cutting insert sizes

6 · best lathe inserts

7 · best cnc inserts

Waterproof your outdoor splices with the DryConn small, aqua/orange wire .

what is a cnc insert

There are many parameters to consider when choosing turning insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and entering (lead) angle, to achieve good chip control and machining . Choosing correct insert for angle/ radius - lathe job. Thread starter Neil101; Start date Sep 30, 2022; Replies 9 Views 537 N. Neil101 Aluminum. Joined May 20, 2022. Sep 30, 2022 #1 Hey guys, . CNC Machining. ABOUT PRACTICAL MACHINIST.Factors to Consider When Choosing CNC Machine Inserts . Selecting the most suitable insert for your machining application involves several factors, some of which are: 1. Type of Material: The material of the workpiece plays a critical role in selecting the correct insert. Harder materials require inserts with greater wear resistance and thermal .Cnc Machining Choosing Inserts. Machine Type: CNC (Computer Numerical Control) Milling Machine Max Workpiece Size: 1000mm x 800mm x 500mm Tool Magazine Capacity: 20 Tools Spindle Speed: 10,000 RPM Control System: CNC System with Advanced Graphical User Interface Accuracy: ±0.01mm

Choosing Machining Tool Inserts for CNC Aluminum Parts . Picking the right machining tools or tool inserts plays a key role in improving the quality of CNC aluminum parts. Aluminum is an abundant metal that is ideal for use across diverse industries. This non-ferrous metal is easy to machine and has the needed chemical and structural qualities . How to Choose the Right CNC Insert. Choosing the right CNC insert can be a daunting task, especially for beginners. The first step is to consider the material to be machined. Hard materials require tough inserts, while soft materials require sharp inserts. The second step is to consider the cutting speed, feed rate, and depth of cut.Choosing the Right CNC Cutting Tool Increases Efficiency by 30%. Admin; 2024/1/18; The CNC tools selected according to different purposes are also different. Choosing the right CNC cutting tools can not only ensure the stability of the processing, but .

The site will have a grade/chipbreaker selector whereas you pick the insert shape, then nose radius, then material, then type of operation (roughing, medium machining/general purpose, finishing, etc). If all works well, this will lead you to the exact insert you should need. My goal is for you to be able to find your tool in 4 clicks.CNC machining has become an essential process in the manufacturing industry. Cutting inserts are an integral part of CNC machining, and selecting the right cutting inserts is crucial to achieve the desired results. This article discusses the various considerations that need to be taken into account when choosing cutting inserts in CNC machining.With a larger insert size, the stability is better. For heavy machining, the insert size is normally above IC 25 mm (1 inch). When finishing, the size can in many cases be reduced. How to choose insert size. Determine the largest depth of cut, a pCBN inserts can also be coated; medium-grain size CBN material with a TiCN coating is recommended for machining hardened steels. How can BIG DAISHOWA help when it comes to PCD and CBN inserts? We are not a carbide, nor a PCD/CBN producer/manufacturer, but we have a lot of knowledge here in-house and are always willing to help metalworkers.

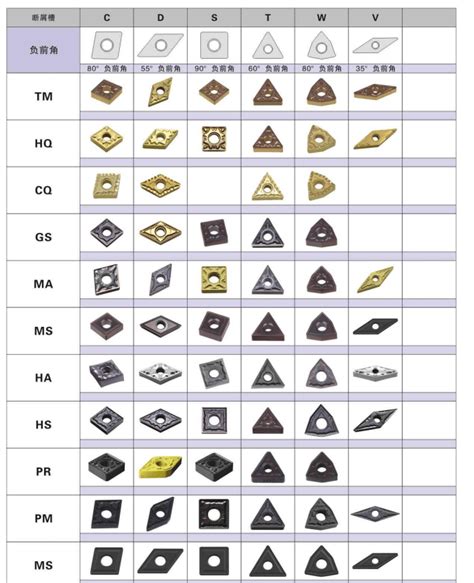

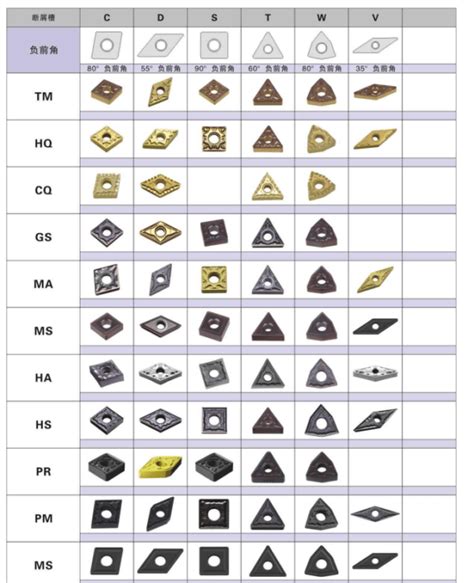

Discover the ultimate guide for selecting the perfect CNC tools for your machining needs. Make informed decisions with expert advice and insights. +86 182 5553 3523. [email protected]. . How to choose the right carbide CNC inserts? Choosing the right carbide CNC insert is very important as it determines the quality of the machining . The Job Shop’s “Go-To” Handbook for Choosing CNC Turning Insert Shape. indexable cutting tools. Posted by: [email protected] on 2/12/2024. . you want the strongest and most stable 80° style insert. If your machine has 1” shank tools, then things are a bit more in the middle. The decision line is likely based on how much power you . How to choose the right turning insert geometry? There are three basic types of turning grooves, suitable for finishing cutting, medium cutting and rough cuttining.The chip breaker type of the blade is selected according to different machining operations and machining materials. The following introduces the three basic machining operations.It also showed the preferred .

ABOUT PRACTICAL MACHINIST. With more than 10.6 million unique visitors over the last year, Practical Machinist is the most visited site for metalworking professionals. Practical Machinist is the easiest way to learn new techniques, get answers quickly and discuss common challenges with your peers. CNC Machining . Indexable drills, questions. Thread starter DDoug; Start date Nov 25, 2008; Replies 20 Views 17,957 1; 2; Next. 1 of 2 Go to page. Go. Next Last. D. DDoug Diamond. Joined Oct 18, 2005 Location NW Pa. Nov 25, 2008 #1 . Same ID and OD insert, several grades to choose from, 4 edges and so far I believe it has most of the .

One crucial aspect of CNC turning is the use of turning inserts, which are cutting tools that are inserted into the machine to remove material from the workpiece. Choosing the right type of CNC turning inserts and a reliable supplier can significantly impact the quality and efficiency of the turning process. In this article, we will explore the .

Haas threading inserts are available for machining various shapes of internal or external threads at various pitches, while ensuring high-quality performance. These laydown thread inserts have 3 cutting edges, and options for different forms of chip breaker, for a range of different IC sizes.

There are several variables that go into choosing the correct insert for your milling operations: the specific cutter body being used (milling cutter series), the type of machining operation (toolpath type), the cutting-edge angle (lead angle), the depth of cut, the materials being cut, and more. Use the filters on the left-hand side below to narrow down your choices, and find the inserts you .

I choose inserts based upon 30 years of mistakes..and a couple of successes. . Screw Machine Parts and CNC Machining - Progressive Turnings - G. gregormarwick Diamond. Joined Feb 7, 2007 Location Aberdeen, UK. Dec 26, 2010 #11 PixMan said: So what is it about trigon inserts that has formed your opinion that they are "worst insert ever . Choosing Machining Tool Inserts for CNC Aluminum Parts Picking the right machining tools or tool inserts plays a key role in improving the quality of CNC aluminum parts. Aluminum is an abundant . I have three different materials and I have no idea what insert to choose for the different materials I need to turn. 1. Tungsten 2. TZM Molybdenum 3. Grade 2 Titanium can anyone assist me with picking out the correct turning inserts for these. CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the .

Personally, I'd focus on an insert designed for 300-series stainless steels, with a sharper edge prep, and start there. I have experience with ceramic inserts, but it's always been with turning hardened steels & cast-irons. Neither material is friendly to sharp cutting edges, and are machine quite well with honed/t-land edge-protection inserts.

types of machining inserts

They are gaining popularity in the automotive industry and elsewhere, and they pose special machining challenges. The CBN inserts that are so productive cutting alloys with greater than 50 Rc hardness can fracture if they hit softer materials. PCD inserts able to machine abrasive aluminum suffer excessive wear cutting ferrous metals. Choosing between negative and positive turning inserts depends on your specific machining needs, including the material being machined, the type of operation, and the capabilities of your machine. By understanding the strengths and limitations of each insert type, you can select the tool that best meets your requirements, leading to improved .

CNC wiper inserts are a type of cutting tool used in the machining industry for cutting and finishing operations. These inserts are made using computer numerical control (CNC) technology, which allows for precise and accurate cutting.In this blog, we will discuss the features and benefits of CNC wiper inserts, as well as their applications and .

water proof electric plastic junction box

Waterproof IP68 External Junction Box, 2 Way Plug Line M20 Coaxial Cable Connector Wire Range 5 to 15mm Outdoor External Electric Power Cord Boxes (Black-2pcs)

cnc machining choosing inserts|cutting insert sizes