c-code g-code cnc-code machine-code CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) Steel wool is an excellent alternative to fine sandpaper for different sanding projects. Plus, it can be used for a wide variety of polishing and cleaning purposes.

0 · how to understand g code

1 · g code explained with examples

2 · g code commands cheat sheet

3 · free downloadable g code files

4 · complete g code list

5 · cnc mill g code list

6 · cnc machine g code list

7 · cnc g code cheat sheet

Avoid accidentally bending, scoring, or gouging the metal in your next DIY project when you follow this technique for how to cut sheet metal.

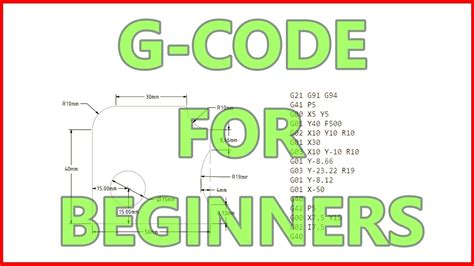

G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections . So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of . Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t .

how to understand g code

g code explained with examples

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .

Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.

G-code and M-code are fundamental to the operation of CNC machines, providing detailed instructions for machine movements and auxiliary functions. Understanding and optimizing these codes can significantly enhance .

G-code is the primary programming language of CNC machines. It relates to the geographical coordinates of the machine arm so that it knows how and where to move. Without this code, your CNC machine would be a . G code, sometimes called g-code, is a simple programming language for CNC machines. Listed below are the codes that use the G word. These codes are preparatory commands. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively.

I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

So you’d like to play with a g-code file (the numerical control programming language used by cnc machines) but don’t have any sample g-code? For starters, be sure to check out our Free G-Code Tutorial. It’s full of examples on a case-by-case basis for all the common g code commands used by your machine tool. Want completed programs? Take one machine that can process a coordinate system rotation based on probe inputs. You’ll need a set of G-code commands that can enable or disable this rotation. Another machine without this adjustment capability won’t require that G-code.CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide) In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications.

Complete list of cnc machine G codes and M codes. This G code and M code list can be used as reference while programming or learning cnc machine programmin.G-code and M-code are fundamental to the operation of CNC machines, providing detailed instructions for machine movements and auxiliary functions. Understanding and optimizing these codes can significantly enhance machining efficiency, precision, and overall productivity.

g code commands cheat sheet

Q: Note 1 indicates 10 GAGE 1010-1020 sheet metal can be used to make the main body of this part. A: Tolerance is the difference between the maximum size and the minimum size of the part or element.Sheet metal thickness is vital for vehicle durability. The standard measurement for this thickness is “gauge,” with a higher gauge number indicating a thinner piece of metal. The gauge system is often used in conjunction with .

c-code g-code cnc-code machine-code|cnc g code cheat sheet