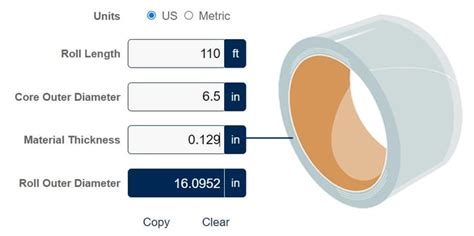

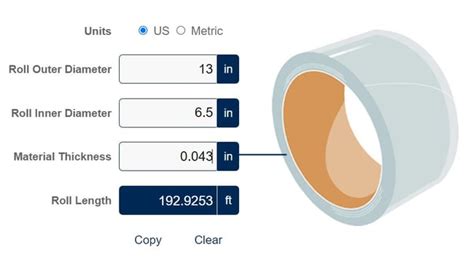

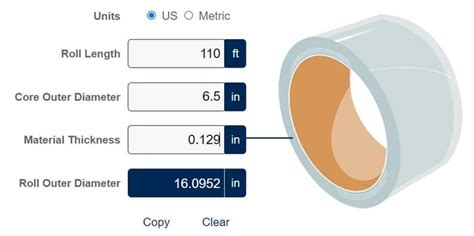

sheet metal rolling calculator Calculates the rolled length of a roll of material when the outside diameter of the material, thickness of the material, and the diameter of the hole in the center or the tube on which the material is wound are given. Variations due to stretching . These tricks and tips would make MIG welding of thin sheets easy, smooth, and swift. Thus, let’s get into the MIG welding techniques if you don’t want to ruin the entire process and the thin sheet metal. When you MIG weld any metal sheet, you must look at and care for two things. Burning through the sheet itself.In this article, we will tell you how to weld titanium. Titanium has a few properties that play a critical role in the welding process. A proper titanium weld will look like frozen mercury – it will be shiny and reflective.

0 · roll square foot size calculator

1 · roll length calculator by weight

2 · roll diameter to footage calculator

3 · plastic film roll length calculator

4 · linear footage per roll calculator

5 · calculator diameter for outside roll

6 · calculate roll length from diameter

7 · calculate footage on a roll

If the hole is small, you can close it just by spot welding. You won’t need to use a bronze backing. The steel from the torch’s wire will fill in the hole.

roll square foot size calculator

Calculate the length of a roll of material using its inner and outer diameters and thickness. This calculator does not apply to sheet metal rolling, which is a different process.Easy to use Roll Length Calculator: find the length of a roll of material by entering the outside diameter, inside diameter, and thickness. To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter .When it comes to curved steel, finding the precise measurements is a challenging undertaking. To solve this, CMRP provides easy-to-use measurement calculators.

Calculates the rolled length of a roll of material when the outside diameter of the material, thickness of the material, and the diameter of the hole in the center or the tube on which the material is wound are given. Variations due to stretching .Roll Length Calculator Enter any three of the four values below and click “Calculate”. The remaining value will calculate for you.This roll length calculator will help you find the length of any rectangular sheet which has been rolled up!

Plate rolling is a widely used technique in metal fabrication that involves bending and shaping metal plates to achieve desired shapes and curves. One crucial aspect of plate rolling is .Deep Drawing Force Calculator. Sheet thickness (in): Blank diameter (in): Punch diameter (in): Ultimate tensile strength (psi): Factor of safety: Drawing ratio: Sheet metal rolling is another method of bending steel, but in this case the goal of manufacturing is to achieve a rounded circular bend, under specific radius, rather than a V-shaped angular form.An example of rolled material would be a rolled carpet or a rolled sheet of paper from the paper mill. The length units that can be used are yard, feet, inch, meter, centimeter, millimeter, mil, and micron. A mil is equal to one thousandth of an .

The sheet metal blank size is determined by considering factors like part dimensions, material thickness, bend allowance, stretch allowance, bend radius, minimum bend distance, material properties, K-factor, drawing ratio, .Calculator for Steel sheets and plates Calculators Steel sheets and plates Seamless steel pipes - circular Hollow structural sections - circular Hollow structural sections - square Hollow structural sections - rectangular Round .The curved steel cone calculator from Chicago Metal Rolled Products makes it easy to find the precise curved steel cone dimensions you need. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . "The rolling on these rectangular tubes was absolutely perfect! Barely any adjustment needed to be made."

Sheet Metal and Plastic Bending Calculator. . The K-factor in sheet metal bending represents the ratio between the thickness of the metal and an invisible line called the “neutral axis.” When a flat piece of material is bent the inside face of the bend is compressed and the outside part stretches.Metal gets heavy, and whether you want to see how much shipping is likely to be, or if your vehicle (or back) can handle it, it’s good to know what your order weighs. To help with that, we’ve got our handy weight calculator here. Fill out the information below and it will tell you how heavy that piece of material is.

Calculate the weight of steel and other metals such as copper, aluminium or stainless steel, the length of the strip, the outside diameter and the weight of the roll with our calculator. The company News

The K factor for rolled steel can vary depending on the type and thickness of the steel. It’s a factor used in sheet metal bending calculations. What is the K factor of plate rolling? The K factor for plate rolling depends on the plate’s material and thickness and is used in bending calculations for plates.

[In this interactive object, students read how to calculate the blank size for cylinders in a three-roll pinch roller. Thanks for viewing this video. We hope.

The curved steel radius calculator from Chicago Metal Rolled Products provides an easy and effective way to find your correct curved steel measurements. . Sheet Metal Bending; Stainless Steel Bending; Calculators. Radius Calculator; . "The rolling on these rectangular tubes was absolutely perfect! Barely any adjustment needed to be made." Sheet Metal Bending Calculator (Free to Use) Y Factor Calculator; Bend Allowance Calculator; Bend Deduction Calculator. Recommended for you: Press Brake FAQs: Get Your Ultimate Answers; Press Brake Bending Basics: A Complete Guide; 0° – 180° Bend Allowance Chart for Sheet Metal Bending; Fig. 2 Pressure (bending force) acting on the roller. P 1: Pressure of the first roller on the steel plate; P 2: Pressure of the second roller on the steel plate; P 3: Pressure of the third roller on the steel plate; t: Roll pitch; In the calculation, the bending moment of the steel plate under the second roll is assumed to be pure plastic bending moment M s, that is, M 2 = M s .Depending on the quantity and geometric parameters of metal products, the online metal calculator will calculate the values. How Does Sheet Metal Differ from Coil Metal? Steel sheet metal is manufactured in a rectangular shape of a certain size. The standard provides for the manufacture of sheets in sizes 1250mm*2500mm and 1500mm*6000mm.

Select the material of the sheet metal from the dropdown menu. The calculator includes common materials like mild steel, stainless steel, aluminum, and copper, each with its corresponding shear strength value. Step 5: Calculate Punch Force. Click the “Calculate Punch Force” button. The calculator will process the input data and display the .

roll length calculator by weight

How to Calculate Bend Allowance in Plate Rolling: Unlocking the Secrets of Precise Metal Forming. In the realm of metalworking, precision is paramount. When it comes to plate rolling, achieving the perfect bend requires meticulous calculations and an understanding of the material’s behavior. . 3 Sorts of Sheet Metal Processing Equipment . These software provide sheet metal modules or related functions that can help designers with the design and unfolding calculations of sheet metal parts. Use the sheet metal module or tools in the software: Most 3D CAD .

Metal sheet weight calculator. Dimensions and weight of sheet products from hot-rolled, galvanized, stainless steel and other metals and alloys. Sheet / Plate. Thin and heavy plate in the form of sheets and wide sheet strips, produced by . In this video, I am going to explain about, How to Develop the Blank Flat Length for a Cylinder Sheet. Here, I am going to explain, how to calculate "Blank F.Plate rolling/sheet metal rolling is a metal forming process used to create cylindrical and curved components from flat sheets or plates of various metals. . the width of the plate, and the desired curvature of the finished product. Here are the basic steps to calculate plate rolling: Determine the plate thickness: Measure the thickness of .Sheet Metal Bending Parameters Calculator Here you can insert the characteristics of the sheet metal to be bent (internal radius, V-die opening and minimum flange) . The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel. Bending Force Calculation Our press brake bending calculator can help you based on the [.]

Fig. 2 Normogram to calculate “h” 2. A graph algorithm for calculating “h” of a certain type of symmetric three roller plate bending machine, which can roll the common point graph under different thicknesses and curvature radii;. As known above, when a certain type of bending machine is given, its parameters a, R 1 and R 2 are fixed.. Then, if the relationship .Why Should Use this Cone Calculator. Cone Calculator is helpful for Generating Flat Pattern Layout or Fabrication Layout of all types of cones. This Calculator gives a complete solution to all types of Cones Fabrication Layout. You Can save the Cost of Material by using this calculator. You can Save Time on your Fabrication Layouting process.At K-Zell Metals, we offer a calculator for sheet metal flat cone templates that shows you how to manually layout a single cone gore section. Try today! PHOENIX, AZ. CALL TODAY (602) 232-5882. . Sheet & Plate Rolling; Angle & Tube Rolling; Industries Served; Projects. Photo Gallery; Portfolio; About Us. Meet the Team; Business Software .

Instructions For Rolling Metal Calculator: Enter your material's elongation, tensile strength, select the units for tensile strength, and hardness in the form below. Then select "Calculate" to determine if the material can be thread-rolled. Please Note: The material thread rollability calculator is intended for general information purposes only. . We make no representations or .Metal weight calculator online - free steel weight calculator. Has pre-entered densities for dozens of commonly-used metals and metal alloys like steel, aluminum, nickel, iron, copper, cadmium, gold, silver, etc. Calculate the weight of a steel beam, bar, tube, profiles, channels, or a . In general, rolling a metal sheet into a cylindrical workpiece on a four-roll bending machine consists of four processes, namely: Center alignment; Pre-bending; Rolling; Roundness correction; During the operation of the rolling machine, the front end of the plate is placed between the upper and lower rollers and aligned with one of the side .

liquid tuff outdoor outlets junction boxes

At Worldwide Steel Buildings, we have a variety of house plan options, from 720 square feet all the way up to 3,600 square feet. Every barndominium is built with the durability and high-quality craftsmanship that we’re known for and come with a 50-year structural warranty to .

sheet metal rolling calculator|plastic film roll length calculator