stainless steel & plastic tool box Corrosion resistanceAlthough stainless steel does rust, this only affects the outer few layers of atoms, its chromium content shielding deeper layers from oxidation. See more cnc turning parts processing price list,SLD Precision specializes in delivering high-quality CNC turning parts for various industries. With state-of-the-art technology and a commitment to excellence, trust us for precise and reliable manufacturing solutions.

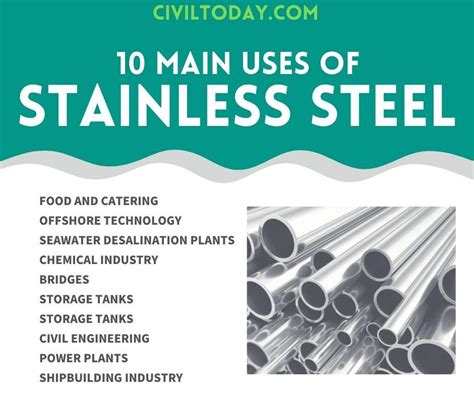

0 · what is stainless steel used for

1 · types of stainless steels

2 · types of stainless steel charts

3 · strongest type of stainless steel

4 · strongest grade of stainless steel

5 · stainless steel pros and cons

6 · grades of stainless steel chart

7 · different types of stainless steels

Our production range includes CNC processing center, automatic lathing, automatic milling, wire cutting, powder metallurgy processing and assembly of metal parts with plastic parts. We produce high quality custom cnc parts products and specialize in cold heading, threading, shaving, pointing, slotting, and grinding product to close tolerances .

Stainless steel, also known as inox, corrosion-resistant steel (CRES), and rustless steel, is an alloy of iron that is resistant to rusting and corrosion. It contains iron with chromium and other elements such as molybdenum, carbon, nickel and nitrogen depending on its specific use and cost. Stainless steel's . See moreCorrosion resistanceAlthough stainless steel does rust, this only affects the outer few layers of atoms, its chromium content shielding deeper layers from oxidation. See moreOver 150 grades of stainless steel are recognized, of which 15 are the most widely used. Many grading systems are in use, including US See moreStandard mill finishes can be applied to flat rolled stainless steel directly by the rollers and by mechanical abrasives. Steel is first rolled to size and thickness and then annealed to change the properties of the final material. Any oxidation that forms on the surface ( See more

The invention of stainless steel followed a series of scientific developments, starting in 1798 when chromium was first shown to the French Academy by Louis Vauquelin. In the early 1800s, . See more

Stainless steel is classified into five main families that are primarily differentiated by their crystalline structure:• Austenitic• Ferritic• Martensitic• See moreUnlike carbon steel, stainless steels do not suffer uniform corrosion when exposed to wet environments. Unprotected carbon steel rusts readily when exposed to a combination of air and moisture. The resulting iron oxide surface layer is porous and fragile. In . See moreA wide range of joining processes are available for stainless steels, though welding is by far the most common.The ease of welding largely depends on the type of stainless . See more stainless steel, any one of a family of alloy steels usually containing 10 to 30 percent chromium. In conjunction with low carbon content, .

Stainless steel is the general name for a family of steels that are corrosion-resistant and contain a minimum of 10.5% chromium. The effect of this minimum level creates a chromium oxide layer on the surface, which is a self . ASTM A572 Grade 50: This is a high-strength, low-alloy carbon steel used in structural applications. ASTM A53: This is used for mechanical and pressure applications, as well as for steam, water, gas, and air lines.It’s . What is Stainless Steel? We know that steel is an alloy of iron and carbon with a maximum carbon content of 2.1%. Stainless steels are a group of steels that are resistant to corrosion through the addition of alloying elements.. . Professional chefs regularly use carbon steel and stainless steel pans since both do well on a stovetop. Still, each type of pan comes with its own unique strengths. Learn how to compare carbon steel and stainless steel pans.

cnc machining center precision machine tool parts after-sales service

AISI 304 Stainless Steel (UNS S30400, SS 304) AISI 304 stainless steel (UNS S30400) is the most widely used stainless steel, containing 18-20% Cr and 8-10.5% Ni, and also known as 18-8 stainless steel.SS 304 is non-magnetic under annealing conditions, but after cold working (such as stamping, stretching, bending, rolling), part of the austenite structure may be converted into .In metallurgy, stainless steel is a steel alloy with at least 10.5% chromium with or without other alloying elements and a maximum of 1.2% carbon by mass.Stainless steels, also known as inox steels or inox from French inoxydable (inoxidizable), are steel alloys, which are very well known for their corrosion resistance, which increases with increasing chromium content.AISI 316 Stainless Steel (UNS S31600) AISI 316 stainless steel (UNS S31600) is the second most commonly used austenitic stainless steel. Due to the addition of Molybdenum (Mo), SS 316 has a great improvement in corrosion resistance and certain properties compared to SS304.

Austenitic Stainless Steel Grades. Austenitic stainless steel contains at least 16% chromium and 6% nickel, is non-magnetic when annealed, and has excellent heat, cold, and corrosion resistance. It cannot be hardened by heat treatment. It is often used in food and healthcare applications, as well as in manufacturing outdoor enclosures and cryogenic . The stainless steel grading system attempts to differentiate alloys by toughness, corrosion resistance, magnetic properties, and composition. The first grading system was developed by the SAE (US Society of Automotive Engineers) using a 3-digit code, with grades belonging to 100, 200, 300, 400, 500, and 600 series classifications. 347 Stainless Steel Physical Properties. 347 stainless steel is an material of grade 347, most known for its excellent oxidation and corrosion resistance. It also possesses great strength at high temperatures, making it ideal for many industrial applications where high-temperature environments exist.

Naturally iron (Carbon steel) is reactive to oxygen. Iron reacts with oxygen and converts to iron oxide as rust. But when carbon steel is added with a minimum of 10.5% chromium, chrome forms a passive layer on the material surface to protect it from rust and corrosion as explained in the below picture.

Chemical Composition % By Mass Max Martensitic Stainless Steels. Martensitic stainless steels can improve mechanical properties by heat treatment, chromium alloy is a key element containing 12–14% content, which is lower than that of Ferritic stainless steels, Generally, they also contain 0.1 to 1 percent carbon, 0.2 to 1 percent molybdenum and, less than 2 percent nickel, they . Strength is a critical factor in metal uses, for example, some applications require stronger aluminum parts, while some products need high steel hardness or yield strength of steel, this may determine the selection of CNC machining material or product design. Here we collect the metal strength chart (tensile, yield strength, hardness, and density included) and .Steel as an engineering material finds diverse applications. The basic components of all steel materials are iron and carbon. Even though Steel signifies a broad range of ferrous metal alloys, most people divide it into two broad categories; Carbon Steel and Stainless Steel.440C (UNS designation S44004) is a martensitic 400 series stainless steel, [1] and has the highest carbon content of the 400 stainless steel series. It can be heat treated to reach hardness of 58 to 60 HRC.It can be used to make rolling contact stainless bearings, e.g. ball bearings and roller bearings.It is also used to make knife blades.. 440C has the highest strength, hardness, .

Crock-Pot 7 Quart Oval Manual Slow Cooker, Stainless Steel (SCV700-S-BR), Versatile Cookware for Large Families or Entertaining a designers' handbook series no 9004 high-temperature characteristics of stainless steels nidi distributed by nickel development institute produced by What is Stainless Steel. Stainless steel is a type of steel. Hence, it also is a metal alloy. It is a mixture of iron and chromium. Unlike the carbon content in normal steel, the chromium content of stainless steel is about 30%.

what is stainless steel used for

types of stainless steels

SS 440 Stainless Steel. SS 440A, 440B and 440C stainless steel are AISI and ASTM standard high carbon high chromium martensitic stainless steel, SS440 has high strength, good hardness, corrosion resistance, wear resistance and high temperature dimensional stability. For AISI 440 stainless steel datasheet, heat treatment and equivalent chart, please see the tables below. At their core, nonstick pans are generally made of aluminum, and then coated with a nonstick material (either PFOA-free Teflon or ceramic). A light, weightless pan may seem ideal, but when .AISI 316L Stainless Steel (UNS S31603) AISI 316L stainless steel is a modified ultra-low carbon Cr-Ni-Mo series austenitic stainless steel based on AISI 316.It is recommended for parts that cannot be annealed after welding in certain corrosive environments.

Physical Properties. Type 310 grade stainless steel physical properties are listed in the table below such as density, melting point, specific heat, electrical resistivity, elastic modulus (modulus of elasticity), thermal conductivity, and coefficient of thermal expansion (CTE).Name Designation EN EN Number Designation Designation AISI/ASTM s r e h t O i N o M r C N S x a m P n M i S C X12CrMnNiN17-7-5 1.4372 201 0,15 1,00 5,50 to 7,50 0,045 0

M390 is one of the new super steels on the block, manufactured by Bohler-Uddeholm (result of merger of Austrian Bohler and Swedish Uddeholm). It uses third generation powder metal technology and developed for knife blades requiring excellent corrosion resistance and very high hardness for excellent wear resistance. When it comes to metal fabrication, there are many different types of steel that can be used.Two of the most common types are structural steel and stainless steel. Although these two materials have similar properties, they differ in terms of .

The SAE steel grades system is a standard alloy numbering system (SAE J1086 – Numbering Metals and Alloys) for steel grades maintained by SAE International.. In the 1930s and 1940s, the American Iron and Steel Institute (AISI) and SAE were both involved in efforts to standardize such a numbering system for steels. These efforts were similar and overlapped significantly. If you're looking to buy steel, it's important to know the differences between hardened steel and stainless steel. Learn more in this blog post.

Atlas Quality Management Scope: National Doc: Information Notice Stainless Steel 420 Grade Data Sheet Controlled Intranet Document Authorised: John Pearson Page 1 of 3 Revised: 28/04/2021

cnc machining center 5 axis quotes

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

stainless steel & plastic tool box|types of stainless steels