tool offset cnc machine CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . Following are the 9 different types of sheet metal operations: It is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end.

0 · what is tool offset

1 · what is tool length offset

2 · tool offset meaning

3 · tool offset definition

4 · offset turning on cnc lathe

5 · offset meaning in cnc programming

6 · fixture offset cnc

7 · cnc tool offsets explained

According to the World Steel Association, there are over 3,500 different grades of steel. At its core, steel is composed of iron and carbon, but the . See more

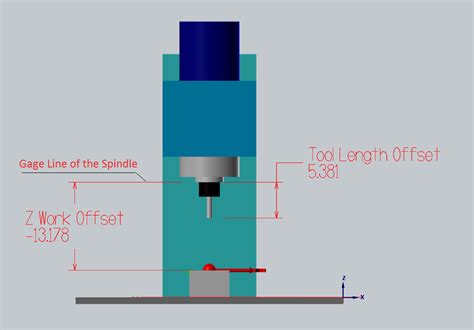

Learn all about CNC offsets and how they are used in CNC machining. Includes info on how to use them and what to watch out for. By letting the machinist set a z-axis datum for each part, the tool length offset enables the CNC machine to compensate for many tools of different lengths. This ultimately enables machinists to use multiple tools without . In this episode, Mark shows you how to properly. and accurately. set a tool length offset and a work offset. One of the most common ways to crash a machine is with an .Taking offsets correctly is essential to achieve the desired precision in CNC machining. Accurate offsets eliminate errors caused by variations in tools, fixtures, and workpiece setup. By .

CNC machine tool offsets are a fundamental aspect of modern machining operations. By understanding the different types of offsets, their practical applications, and implementing best . This article will explain all you need to know about tool length offsets and setting tool length offsets Fanuc. Ok so you managed to write a CNC Programme for your CNC Milling Machine, well done. A CNC program is a set .Talking about Tool Length Offsets and how they are set on a CNC Mill. This video covers the 3 most common methods and the benefits and drawbacks of each.

CNC Tool Length Offsets Explained. This video is talking about the 3 most common Tool Length Offsetting methods used on CNC milling machines, and the pros and cons of each.Learn how to set the datums an a Cnc Machine. Critical Cnc knowledge from a professional! Understand what cnc offsets are, how they are used, and how they relate to a cnc machines home position.Just FYI how tool offsets are set in the machine have very little to do with programming. Programmers will call out specific locations to set work offsets, but it's up to shop SOP or the machinist on how to develop the relationship between Z and your TLO. Typically you'll see large negative numbers in a Z offset if you use positive tool offsets.

what is tool offset

The machine should know the offset between the reference point of first tool and that of the next tool, when the tools are brought into the cutting positions. This is called tool offset. If the WCS is set up using a particular tool, it may be called the master tool, for which tool offset would be zero (in ideal case). Here is what I was talking about, you would use a work offset in the main program for the cycle with the tool in question..and you would apply the work offset and add or subtract the value of #101 from it, I would also use a tool life macro to change the tool, and this macro would set the value of #101 back to 0 Tool radius compensation allows the CNC machine to adjust the toolpath based on the actual size of the cutting tool used. With G41 (left-hand side) or G42 (right-hand side) active, the machine offsets the programmed path inward or outward by half of the tool’s diameter, resulting in accurate cuts.

CNC KNOWLEDGE is definitely the CNC Machinist Online Resources. You are warmly welcome to the world of CNC (Computer Numerical Control). CNC KNOWLEDGE provides free and detailed articles about cnc programming and machining etc. Easy to understand cnc programming examples are described with detail and images.CNC KNOWLEDGE is for . This video is talking about the 3 most common Tool Length Offsetting methods used on CNC milling machines, and the pros and cons of each method.Method 1 - Fo.

arizona metal fabrication llc

Now I need to incorporate tool changes, here is the procedure I used to set up the tool offset table: I home the machine to machine zero, then I assembled tool 1 with a 1/2" dowel pin as reference tool and measured from the gauge line to tip at 3.6825 using a height gauge on a surface plate with a taper fixture (the 3.6825 is the net length . In this crude drawling when I touch off the 2" side of the 1-2-3 block the machine's Z reads -18.000" so in the offset page under the tool number I'm using, I hit tool offset measure button then with same tool selected go to command and type -2.000 enter or (+ -2.000) which allows for 2" block/standard that will set the table at -20.000 machine .Tool offsets tell the machine: At this machine coordinate, the tool nose of this specific tool, is at “this position”, relative to the face or outer diameter of the stock. . A subreddit for enthusiasts of Hobbyist CNC machines like the Shapeoko, X-Carve, 6040, etc Members Online. Feeds/ material calculator for dremmel cnc? comments. r . Hi thanks for adding me. This is a new problem and we are stumped. Mazak Quickturn Nexus350myII Using G-code Mastercam 2017. (Same issue with Mastercam X5) Something changed we believe in a parameter or setting.In lathe mode used to be able to use 2 offsets for 1 tool. Eg. tool 1 offset 21 or.

2 Global Offset System 2.1 Why Global Offset A CNC machine tool is designed with a table to mount a fixture and locate a part on the fixture for machining. The fixture is aligned to the table and the table is installed on the CNC machine. Due to imperfections in the machine and fixture manufacturing, the actual table center and fixture center . Conventional offset is widely used in CNC machining industry and it is the current available offset approach in machine tools. Conventional offset coordinate systems are used for individual part faces, providing an individual offset for each part face. A conventional offset is defined for a group of features in a single table rotary position. The Global Offset for a machine tool is estimated through a model while utilizing the computed deviation between the measured and nominal dimensions of the part. Examples are provided to .

The formulas are as if the machine X0Z0 is the C/L of the B-axis rotation and the probed bore is programmed X0Y0 with the probed face as Z0. If you have a machine where machine X0Z0 are in another location (usually all the way plus) you would need to .

.001 to.002 is not a sufficient move to make a cut. You are rubbing the tool with a cut adjustment of that depth. You need to adjust by more than the width of the radius/edge of your tool to produce a proper chip and not rub/burn your tool. You run your tool depth for your chamfer, measure it, adjust to depth, then cut a new chamfer.Use Macros to Speed Up Setting Tool Offsets - Haas Automation Tip of the Day. We've made lots of videos where Mark looks at setting the tool and work offsets on your mill. Now he's adding another one and showing us a quick way to set one tool offset or many tool offsets using some simple to understand macro statements.2 Global Offset System 2.1 Why Global Offset A CNC machine tool is designed with a table to mount a fixture and locate a part on the fixture for machining. The fixture is aligned to the table and the table is installed on the CNC machine. Due to imperfections in the machine and fixture manufacturing, the actual table center and fixture center .What are cnc machine offsets? Cnc machine offsets or work coordinate system (WCS) are positions you set that are referenced from your machines home position. You can set multiple offsets in a program.This is usually done when machining several parts at the same time. The offset positions are given Gcode numbers, most commonly G54 through G59.

Learn the process of finding and storing a Work Offset on a 3-Axis CNC Mill.Steps to Take Offsets in CNC Machines . 1. Measure and Set Tool Length Offsets: Accurate tool length offsets are crucial for ensuring proper tool engagement with the workpiece. This section will guide you through the steps of measuring and setting tool length offsets correctly. 2. Calculate and Set Tool Diameter Offsets: Tool diameter offsets .

The machine adds the two values together to determine the total tool length offset. This point will be explained later in your CNC training. Fig. 2.3 Ways to Set Tool Length Offset (TLO) (Image: “Vertical Milling Center Machine Motion” by LamNgeun Virasak, Manufacturing Processes 4-5 is licensed under CC BY-SA 4.0) What I always did was have a tool that I use to set my work offset. Say Tool 1. In my case it was a face mill. That tool has a length offset of 0 in the registry. I touch that tool off to the part face and set my work offset. All tool offsets are then set from the same face. The tool offset lengths are relative to Tool 1.

G49 is a G-code command that cancels the tool length offset (TLO) applied by G43 or G44. TLO is a method of compensating for the difference in length between different tools used in CNC machining. TLO allows the CNC machine to adjust the Z-axis position according to the length of the current tool, so that the programmed coordinates are always .

The part origin is another variable in the system. That is why machines have both a tool offset and a work offset. Tool offset is picked up to a permanent location. Work offset is the delta from the permanent location you picked up the tool from to the part origin. If you run large volume production, it doesn't really matter which one you choose.

On almost all cnc machine controls the tool offset setting and cnc machine zero offset setting ( workshift value, shift value, machine zero offset value) are given on separate pages. But these cnc controls also allow the cnc programmer to add offset values through cnc program. On Fanuc cnc controls we can use G10 (Programmable Offset Setting . and it works the way I want, it goes to the Z reference position and the tool length offset is gone. If I use "G91 G49 Z5.0" or "G91 H0 Z5.0" the machine will first make a Z movement in rapid that is equal to the inverse of the tool offset, meaning that if my tool is 1" long, the machine will first rapid Z-1" and then move up 5" incrementally.

what is tool length offset

ark survival junction box

argos home dbl modular metal framed fabric wardrobe jute

Before you head off to get your materials, here are some of the different types of sheet metal and their advantages and disadvantages. Alloy steel, as the name implies, mixes various components to provide a .

tool offset cnc machine|offset meaning in cnc programming