cnc machine programming codes pdf G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .

As the name implies, recessed lighting fixtures fit into the space above the ceiling. Recessed fixtures produce a strong downward cone of light and are frequently used to provide general illumination, to illuminate work areas such as in kitchens, or to accent art, tables, or other features.

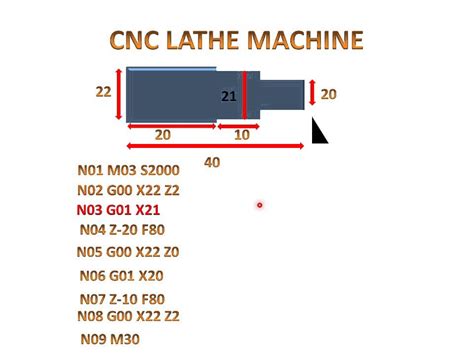

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turn mill programming PDF

3 · cnc programming for beginners PDF

4 · cnc programming codes list PDF

5 · cnc programming PDF free download

6 · cnc lathe programming example PDF

7 · cnc codes PDF download

CNC Machining is a subtractive manufacturing technology, where material is removed from a solid block, or workpiece, using various CNC machining equipment such as milling machines, lathes, and grinders. This process is known for its high precision and versatility in creating a wide range of materials, including metal, plastic, wood, foam, and .

cnc turning program examples PDF

electric box walkthrough level 7

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our .- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has .A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. .

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex .This manual provides basic programming principles necessary to begin program-ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is .G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console of the machine directly. These are all valuable skills that .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .

cnc turning machine programming PDF

To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.This manual provides basic programming principles necessary to begin program-ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733. e-mail: customer_services @denford.co.uk.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.

- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console of the machine directly. These are all valuable skills that .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .To machine any of the parts of these example, use the feedrates and speeds recommended by the tool manufacturer. The tool number will also be different depending on the machine. Programming with this type of coordinates implies the use of a "part zero" as a coordinate origin.

G Code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from mach ine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard.This manual provides basic programming principles necessary to begin program-ming the HAAS C.N.C. Milling Machine. In a fiCNCfl (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

G codes from group B are of "one shot" type (active only in the line in which they are specified). All other G codes are modal (active until another G code of the same group is specified).

In this piece, we will go over key considerations for steel building foundations, introduce some of the most common types of foundations, and provide some additional tips and advice to get you going on the right track.

cnc machine programming codes pdf|cnc programming PDF free download