electron metal fabrication tools Electron beam welding is useful for many applications -- steel, aluminum, and exotic metals; thick, structural sections or thin, delicate . $185.33

0 · Metal Working Tools, Metal Fabrication Tools and Equipment

1 · Harnessing the Power of Electron Beam Welding for Advanced

2 · Fabrication Hacks Clever Tips and Tricks for Optimizing Electron

3 · Electron Beam Welding: The Ultimate Guide to High

4 · Electron Beam Welding Expertise

5 · Electron Beam Free Form Fabrication (EBF3)

6 · Electron

7 · Electrical discharge machining

8 · Characteristics of electron beam welding

9 · A Guide to Electron Beam Welding: Process, Uses,

CNC lathe production can involve a variety of secondary finishes to ensure that the metal parts meet thedesired surface quality after they have finished the machining process A . See more

Metal Working Tools, Metal Fabrication Tools and Equipment

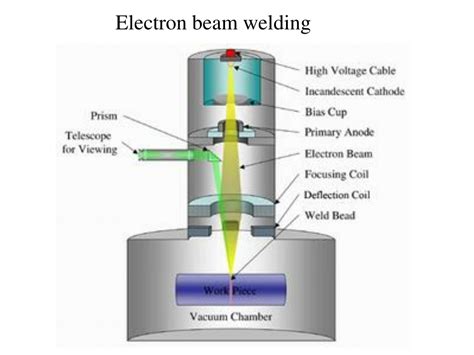

Discover the advantages of Electron Beam Welding in this detailed guide. This article explores everything manufacturing companies, engineers and industries need to know, from its process steps to comparison with traditional . Using a focused electron beam, the exact welding technique known as electron beam welding (EBW) fuses materials. This technology is vital across numerous industries, . By directing a focused beam of high-energy electrons onto the materials in a vacuum environment, electron beam welding achieves deep penetration and minimal heat .Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subjec.

Electron beam welding is useful for many applications -- steel, aluminum, and exotic metals; thick, structural sections or thin, delicate .Custom Metal Fabrication for aerospace, energy and science delivered with precision. An industry leader in EB Welding. One of the largest electron beam welding systems in North America. Extensive quality certifications.Electron Beam Freeform Fabrication, or EBF3, is a process that uses an electron beam gun, a dual wire feed and computer controls to manufacture metallic structures for building parts or tools in hours, rather than days or weeks.

Electron-beam freeform fabrication (EBF3) is an additive manufacturing process that builds near-net-shape parts. It requires far less raw material and finish machining than traditional . This highly specialized process allows us to achieve unparalleled precision and control, making it an invaluable tool in our fabrication arsenal. You know, when it comes to .Trick Tools offers high performance metal fabrication equipment and metal working tools like tube benders, notchers, saws, English wheels, and sheet metal brakes Discover the advantages of Electron Beam Welding in this detailed guide. This article explores everything manufacturing companies, engineers and industries need to know, from its process steps to comparison with traditional Arc welding. Learn about applications, benefits and limitations of EBW to enhance your production in high-demand sectors. What is [.]

Using a focused electron beam, the exact welding technique known as electron beam welding (EBW) fuses materials. This technology is vital across numerous industries, generating robust, clean, and highly accurate joints. By directing a focused beam of high-energy electrons onto the materials in a vacuum environment, electron beam welding achieves deep penetration and minimal heat-affected zones. The result? Incredibly strong, clean, and distortion-free welds that are simply unmatched by conventional welding techniques.Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]

Electron beam welding is useful for many applications -- steel, aluminum, and exotic metals; thick, structural sections or thin, delicate components; and harsh conditions such as alternating loads and low temperatures.Custom Metal Fabrication for aerospace, energy and science delivered with precision. An industry leader in EB Welding. One of the largest electron beam welding systems in North America. Extensive quality certifications.

Electron Beam Freeform Fabrication, or EBF3, is a process that uses an electron beam gun, a dual wire feed and computer controls to manufacture metallic structures for building parts or tools in hours, rather than days or weeks.

Electron-beam freeform fabrication (EBF3) is an additive manufacturing process that builds near-net-shape parts. It requires far less raw material and finish machining than traditional manufacturing methods.

This highly specialized process allows us to achieve unparalleled precision and control, making it an invaluable tool in our fabrication arsenal. You know, when it comes to electron beam welding, it’s all about mastering the intricate dance .

Trick Tools offers high performance metal fabrication equipment and metal working tools like tube benders, notchers, saws, English wheels, and sheet metal brakes Discover the advantages of Electron Beam Welding in this detailed guide. This article explores everything manufacturing companies, engineers and industries need to know, from its process steps to comparison with traditional Arc welding. Learn about applications, benefits and limitations of EBW to enhance your production in high-demand sectors. What is [.] Using a focused electron beam, the exact welding technique known as electron beam welding (EBW) fuses materials. This technology is vital across numerous industries, generating robust, clean, and highly accurate joints. By directing a focused beam of high-energy electrons onto the materials in a vacuum environment, electron beam welding achieves deep penetration and minimal heat-affected zones. The result? Incredibly strong, clean, and distortion-free welds that are simply unmatched by conventional welding techniques.

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). [1]

Harnessing the Power of Electron Beam Welding for Advanced

Electron beam welding is useful for many applications -- steel, aluminum, and exotic metals; thick, structural sections or thin, delicate components; and harsh conditions such as alternating loads and low temperatures.Custom Metal Fabrication for aerospace, energy and science delivered with precision. An industry leader in EB Welding. One of the largest electron beam welding systems in North America. Extensive quality certifications.

Electron Beam Freeform Fabrication, or EBF3, is a process that uses an electron beam gun, a dual wire feed and computer controls to manufacture metallic structures for building parts or tools in hours, rather than days or weeks.Electron-beam freeform fabrication (EBF3) is an additive manufacturing process that builds near-net-shape parts. It requires far less raw material and finish machining than traditional manufacturing methods. This highly specialized process allows us to achieve unparalleled precision and control, making it an invaluable tool in our fabrication arsenal. You know, when it comes to electron beam welding, it’s all about mastering the intricate dance .

how many styles metal for fabricating

Custom Aluminum Parts. eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed.

electron metal fabrication tools|Electron