cnc lathe machine operation tutorial Set-up CNC lathe machine, workpiece and cutting tools; Perform basic CNC lathe machine operations; Career Opportunity. A person with this qualification is competent to be: CNC Lathe Machine Operator (Basic) Training Duration. 18 Hours (Basic) 138 Hours (Common) 80 Hours (Core) Total: 236 Hours $86.49

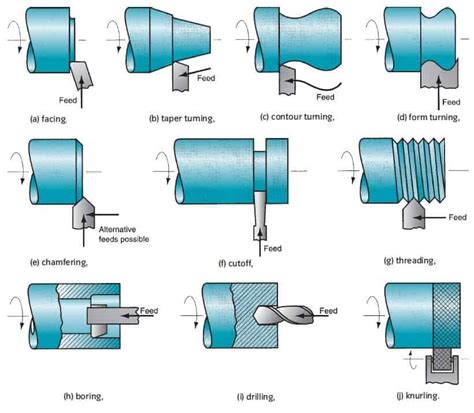

0 · turning operations on lathe machine

1 · turning operation lathe

2 · turning lathe diagram

3 · cnc turning lathe machine

4 · cnc lathe setup

5 · cnc lathe machine operations

6 · basic turning operations

7 · application of cnc lathe machine

The purpose of a fuse is to protect the wire, NOT the amps. The fused distribution block contains the smaller fuses for the amps. If there is an issue with the amp, the distribution block fuses will blow long before the main fuse blows.

Set-up CNC lathe machine, workpiece and cutting tools; Perform basic CNC lathe machine operations; Career Opportunity. A person with this qualification is competent to be: CNC Lathe . This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup . "Learn Lathe Machine Operation, Maintenance, and Troubleshooting with our expert tutorials! Master CNC Lathe, Machine Tools, and Mechanical Engineering skill. CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus .

Set-up CNC lathe machine, workpiece and cutting tools; Perform basic CNC lathe machine operations; Career Opportunity. A person with this qualification is competent to be: CNC Lathe Machine Operator (Basic) Training Duration. 18 Hours (Basic) 138 Hours (Common) 80 Hours (Core) Total: 236 Hours

This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine."Learn Lathe Machine Operation, Maintenance, and Troubleshooting with our expert tutorials! Master CNC Lathe, Machine Tools, and Mechanical Engineering skill.

CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and . How to program CNC machine? Here we bring CNC lathe programming examples, cycle programs, and tips for CNC turning programming. Within these tutorials, a vast world unfolds, where mastery of the Spindle Motor, Tool Turret, Carriage Slide, and complex G-code operations is within reach. Learn to harness the full power of the lathe, program with precision, and optimize operations for peak efficiency.To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

turning operations on lathe machine

In this comprehensive guide, we will take you through the fundamentals of CNC lathe machine programming, covering everything from understanding the basics to mastering advanced techniques. With computer precision, learning how to program CNC lathe combines manual and automated ways to accomplish intricate details and exact cuts that speak for modern manufacturing.Tutorials and programming exercises to describe the working and operation of C-Axis on CNC lathe machine, Extra CNC lathe live-tooling examples.

Set-up CNC lathe machine, workpiece and cutting tools; Perform basic CNC lathe machine operations; Career Opportunity. A person with this qualification is competent to be: CNC Lathe Machine Operator (Basic) Training Duration. 18 Hours (Basic) 138 Hours (Common) 80 Hours (Core) Total: 236 Hours This article walks you through the process of setting up a CNC lathe machine, from choosing the right tools to programming and running the machine. Get expert advice and tips to ensure a smooth and successful setup of your CNC lathe machine."Learn Lathe Machine Operation, Maintenance, and Troubleshooting with our expert tutorials! Master CNC Lathe, Machine Tools, and Mechanical Engineering skill. CNC Lathe Programming for Turning. CNCCookbook’s G-Code Tutorial: Learning g code the easy way. CNC Lathe Axes; Diameter Versus Radius Mode; Basic G01 and G02/03 Moves: Lines and Arcs Part Zero on CNC Turning Programs; Tool Changes and Tool Selection on the CNC Lathe; Automatic Chamfer and Corner Rounding with G01. See Also. Speed and .

How to program CNC machine? Here we bring CNC lathe programming examples, cycle programs, and tips for CNC turning programming.

Within these tutorials, a vast world unfolds, where mastery of the Spindle Motor, Tool Turret, Carriage Slide, and complex G-code operations is within reach. Learn to harness the full power of the lathe, program with precision, and optimize operations for peak efficiency.

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.In this comprehensive guide, we will take you through the fundamentals of CNC lathe machine programming, covering everything from understanding the basics to mastering advanced techniques.

steel metal fabricators sydney

With computer precision, learning how to program CNC lathe combines manual and automated ways to accomplish intricate details and exact cuts that speak for modern manufacturing.

steel lock airtight lunch box

turning operation lathe

turning lathe diagram

This is choosing the right thickness, or gauge, of sheet metal. It is very important that you are using the correct product to optimize efficiency and functionality. In order to measure the sheet metal, you will need a sheet metal gauge handy!

cnc lathe machine operation tutorial|turning operation lathe