can you bend electrical wire 90 degrees into receptical box NMD cable is fine, only rule for it is that it shall not be bent in a way that causes damage(12-508). Bending radius rules start to apply to cable types that could be damaged, such as armoured and mineral insulated. Other conductors are . That's why packing your own lunch is key in maintaining a clean diet. But it's not as simple as throwing whatever you have in a paper bag. Here, we'll explain just what a clean, healthy, filling lunch looks like along with some quick and easy ideas: 1. Protein, always.

0 · wire bend youtube

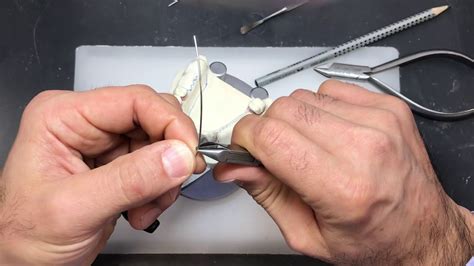

1 · wire bend tips

2 · wire bend instructions

3 · wire bend for wiring

4 · wire bend

5 · nec 90 degree bends

6 · how many bends in 90 degree conduit

7 · 90 degree bend legal

By understanding the advantages and limitations of each material, CNC parts designers can achieve precision and accuracy in their machining projects. Selecting the right materials for CNC machining is a critical step in ensuring the success of the project.

NMD cable is fine, only rule for it is that it shall not be bent in a way that causes damage(12-508). Bending radius rules start to apply to cable types that could be damaged, such as armoured and mineral insulated. Other conductors are . The NEC officially limits you to no more than 360 degrees worth of bends, NEC 346-11. I.e. 4 qty standard 90 degree turns. There is no official limit of length, or limit on .

cnc knee milling machine

National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the . When preparing your wires for connection, it can be frustrating getting the wire shaped to easily curl around the device screw terminals. In my latest video I demonstrate how simple it is to. I suspect that wire has a minimum bend radius between 1 and 2 inches. You can achieve that most easily by just rotating the receptacle. The wire will tail upwards, which will look strange, but it will be behind the range so as .

Do a 90 degree bend to vertical and a 90 degree bend to horizontal to resume 14 inches above ground and arrive at the next receptacle box. What is the practical limit for how .

cnc laser cutting machine 2000w

Update: Thanks all. these issues and comments have made me realize I probably can't use LB bodies for 90 degree turns in my SER cable. Coming up with a whole new plan with just long soft turns. Part of code I read on bending . I want to add an outlet on the wall on the right. The distance from existing junction box to the adjacent wall is only 2-1/2". Using 1/2" EMT, can I bend a 90* and a box offset here, . The issue is damage to the insulation. There is no issue with bending the actual conductor. It does not change its ampacity. As far as lightning protection system conductors, . You might want/need to go from the LB directly into a large junction box and transition to a different type of wire to make the bend. Option #4 would be my suggestion - it .

cnc hydraulic press brake manufacturers

NMD cable is fine, only rule for it is that it shall not be bent in a way that causes damage(12-508). Bending radius rules start to apply to cable types that could be damaged, such as armoured and mineral insulated. Other conductors are pulled into raceways, and raceways also have bend radius requirements.

The NEC officially limits you to no more than 360 degrees worth of bends, NEC 346-11. I.e. 4 qty standard 90 degree turns. There is no official limit of length, or limit on configuration of lengths among the bends. It is up to your pulling tension calculations to determine if a pull is possible.National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.” When preparing your wires for connection, it can be frustrating getting the wire shaped to easily curl around the device screw terminals. In my latest video I demonstrate how simple it is to. I suspect that wire has a minimum bend radius between 1 and 2 inches. You can achieve that most easily by just rotating the receptacle. The wire will tail upwards, which will look strange, but it will be behind the range so as long as you .

I seem to remember if a conduit run had more than 360 degrees of turns, a pull box or pulling C, LB, etc had to be installed. Is there a code restriction, that you cannot continuously pull through more than 360 degrees?

i.e. if the run is long enough, simply having 1 x 90 deg bend could cause cable damage on the pull.

Do a 90 degree bend to vertical and a 90 degree bend to horizontal to resume 14 inches above ground and arrive at the next receptacle box. What is the practical limit for how many degrees of bend between junction boxes or pull openings (such as a flap at an elbow)?Update: Thanks all. these issues and comments have made me realize I probably can't use LB bodies for 90 degree turns in my SER cable. Coming up with a whole new plan with just long soft turns. Part of code I read on bending says bend radius must be at least 5x wire diameter.

wire bend youtube

wire bend tips

I want to add an outlet on the wall on the right. The distance from existing junction box to the adjacent wall is only 2-1/2". Using 1/2" EMT, can I bend a 90* and a box offset here, or should I just bend the 90*, which means the EMT bend won't sit all the way into the wall corner?. NMD cable is fine, only rule for it is that it shall not be bent in a way that causes damage(12-508). Bending radius rules start to apply to cable types that could be damaged, such as armoured and mineral insulated. Other conductors are pulled into raceways, and raceways also have bend radius requirements.

The NEC officially limits you to no more than 360 degrees worth of bends, NEC 346-11. I.e. 4 qty standard 90 degree turns. There is no official limit of length, or limit on configuration of lengths among the bends. It is up to your pulling tension calculations to determine if a pull is possible.

wire bend instructions

National Electrical Code or NEC limits the total number of bends in one continuous run to 360 degrees or four 90 degree bends. It specifically states, “There shall not be more than the equivalent of four quarter bends (360 degrees total) between pull points, for example, conduit bodies and boxes.” When preparing your wires for connection, it can be frustrating getting the wire shaped to easily curl around the device screw terminals. In my latest video I demonstrate how simple it is to. I suspect that wire has a minimum bend radius between 1 and 2 inches. You can achieve that most easily by just rotating the receptacle. The wire will tail upwards, which will look strange, but it will be behind the range so as long as you .

I seem to remember if a conduit run had more than 360 degrees of turns, a pull box or pulling C, LB, etc had to be installed. Is there a code restriction, that you cannot continuously pull through more than 360 degrees?

i.e. if the run is long enough, simply having 1 x 90 deg bend could cause cable damage on the pull. Do a 90 degree bend to vertical and a 90 degree bend to horizontal to resume 14 inches above ground and arrive at the next receptacle box. What is the practical limit for how many degrees of bend between junction boxes or pull openings (such as a flap at an elbow)?

Update: Thanks all. these issues and comments have made me realize I probably can't use LB bodies for 90 degree turns in my SER cable. Coming up with a whole new plan with just long soft turns. Part of code I read on bending says bend radius must be at least 5x wire diameter.

cnc jig grinding machine

cnc internal grinding machine factory

At its core, an electrical distribution box (or distribution board) is a metal or plastic enclosure that houses various components responsible for managing and distributing electricity across .

can you bend electrical wire 90 degrees into receptical box|wire bend tips