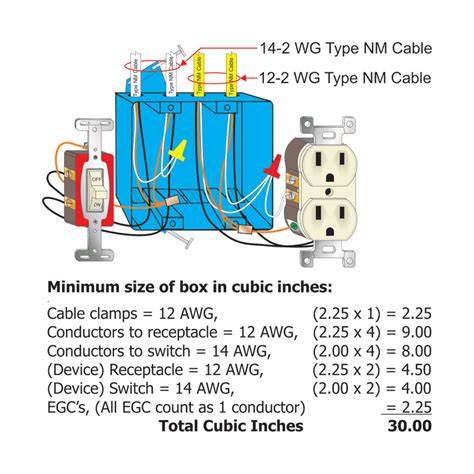

electrical box fill tables Electrical Box Fill Table Information. Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is .

Uses a milling cutter with 8 replaceable carbide inserts; Fast cutting at 6 feet per minute; Adjustable depth of cut; Width of cut in a single pass 1/2 inch; Maximum weld bead height 3/16 inch; 4 hp, 110 volt, 50/60hz; Patented design

0 · fixture box fill calculator

1 · electrical box volume and fill calculator

2 · electrical box volume and fill

3 · electrical box fill chart

4 · electrical box fill capacity calculation

5 · electrical box fill capacity

6 · electrical box fill calculator

7 · 12 awg electrical box fill

$27.99

Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

Enter the required parameters to precisely calculate “Box Fill" requirements for an electrical wiring box. This box fill calculator precisely estimates the total box fill volumes for electrical utility .Box & conduit Fill Calculations Table 5 – Cross-Sectional Area of Individual Conductors 2/0 AWG THW Cu = .2624 X 3 = .7872 4/0 AWG THHN Cu = .3237 X 4 = 1.2984 Total Square Inches .

The total box fill, based on Table 314.16(B), is determined as given in Commentary Table 314.3. With only 26 in.3 of the 36 in.3 filled, the box is adequately sized. In the next Article, I will . Table 314.16(A) seems to make it simple to determine the volume of a box, but don't get too excited. You can use Table 314.16(A) only if the box contains no switches, receptacles, luminaire studs, luminaire hickeys, internal .

Electrical Box Fill Table Information. Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is .Do you need to calculate a box size given the wires that are going into the box? Construction Monkey has the perfect calculator for you. Just answer the questions below and we will do the . We will cover the basics for performing a box fill calculation, after which we will walk through a real-world example. It may be helpful to have a calculator available. The tables in this section, 314.16(A) and 314.16(B), are .To calculate box fill, follow these steps: Count all conductors entering the box. Determine the volume allowance for each conductor based on its size. Add volume allowances for devices, clamps, and fittings. Sum up all volume .

Learn how to calculate box fill accurately for efficient and safe wiring. Enhance your electrical knowledge with this formal guide.

Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.Enter the required parameters to precisely calculate “Box Fill" requirements for an electrical wiring box. This box fill calculator precisely estimates the total box fill volumes for electrical utility boxes, prioritizing safety and electrical system reliability in various installations.Box & conduit Fill Calculations Table 5 – Cross-Sectional Area of Individual Conductors 2/0 AWG THW Cu = .2624 X 3 = .7872 4/0 AWG THHN Cu = .3237 X 4 = 1.2984 Total Square Inches for Conductors = 2.0820 Table 4 – 40% fill column for “Over 2 wires”. 2.0820 Sq.In. Requires a 2 ½ inch EMT Conduit .

The total box fill, based on Table 314.16(B), is determined as given in Commentary Table 314.3. With only 26 in.3 of the 36 in.3 filled, the box is adequately sized. In the next Article, I will explain NEC 314.16 Part (C) and Conduit Fill Calculations .

Table 314.16(A) seems to make it simple to determine the volume of a box, but don't get too excited. You can use Table 314.16(A) only if the box contains no switches, receptacles, luminaire studs, luminaire hickeys, internal cable clamps, or .Electrical Box Fill Table Information. Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire connecting to a device counts as one wire of that size.Do you need to calculate a box size given the wires that are going into the box? Construction Monkey has the perfect calculator for you. Just answer the questions below and we will do the box fill calculations for you based on Article 314.16 of the National Electrical Code. We will cover the basics for performing a box fill calculation, after which we will walk through a real-world example. It may be helpful to have a calculator available. The tables in this section, 314.16(A) and 314.16(B), are important to have on hand in order to do the volume calculation correctly.

To calculate box fill, follow these steps: Count all conductors entering the box. Determine the volume allowance for each conductor based on its size. Add volume allowances for devices, clamps, and fittings. Sum up all volume allowances. Compare the total to the box’s rated volume. Let’s calculate the fill for a box containing:Learn how to calculate box fill accurately for efficient and safe wiring. Enhance your electrical knowledge with this formal guide. Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®.

jack gilchrist metal fabricating

Enter the required parameters to precisely calculate “Box Fill" requirements for an electrical wiring box. This box fill calculator precisely estimates the total box fill volumes for electrical utility boxes, prioritizing safety and electrical system reliability in various installations.Box & conduit Fill Calculations Table 5 – Cross-Sectional Area of Individual Conductors 2/0 AWG THW Cu = .2624 X 3 = .7872 4/0 AWG THHN Cu = .3237 X 4 = 1.2984 Total Square Inches for Conductors = 2.0820 Table 4 – 40% fill column for “Over 2 wires”. 2.0820 Sq.In. Requires a 2 ½ inch EMT Conduit .The total box fill, based on Table 314.16(B), is determined as given in Commentary Table 314.3. With only 26 in.3 of the 36 in.3 filled, the box is adequately sized. In the next Article, I will explain NEC 314.16 Part (C) and Conduit Fill Calculations . Table 314.16(A) seems to make it simple to determine the volume of a box, but don't get too excited. You can use Table 314.16(A) only if the box contains no switches, receptacles, luminaire studs, luminaire hickeys, internal cable clamps, or .

Electrical Box Fill Table Information. Box Fill Guidelines: No matter how many ground wires, they only count as one conductor in the box. A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire connecting to a device counts as one wire of that size.Do you need to calculate a box size given the wires that are going into the box? Construction Monkey has the perfect calculator for you. Just answer the questions below and we will do the box fill calculations for you based on Article 314.16 of the National Electrical Code. We will cover the basics for performing a box fill calculation, after which we will walk through a real-world example. It may be helpful to have a calculator available. The tables in this section, 314.16(A) and 314.16(B), are important to have on hand in order to do the volume calculation correctly.

To calculate box fill, follow these steps: Count all conductors entering the box. Determine the volume allowance for each conductor based on its size. Add volume allowances for devices, clamps, and fittings. Sum up all volume allowances. Compare the total to the box’s rated volume. Let’s calculate the fill for a box containing:

fixture box fill calculator

Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects. This guide explains some of the ways to help get the best results when welding thin sheet metal.

electrical box fill tables|electrical box fill capacity calculation