metal sheet processing machines Global presence, local response. For over 60 years, Salvagnini has been designing, producing and selling machine tools, industrial and flexible automation systems for sheet metal processing. The X-TREME BOX™ portable power distribution center is intended for connection to a split-phase 125/250V 50A power source. This source may be a generator or a utility power drop. .

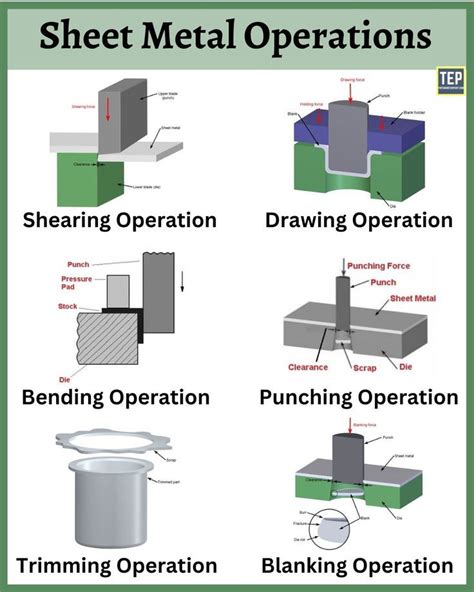

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal process in manufacturing

4 · sheet metal fabrication techniques

5 · sheet metal diagram fabrication

6 · disadvantages of sheet metal

7 · basic sheet metal fabrication techniques

Find out all of the information about the Shanghai Yaohua weighing system co.ltd., product: stainless steel junction box . Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale.

CIDAN Machinery can help build your production facility for the best ergonomics, efficiency and profitability. Sheet metal from coil saves money, reduces waste and frees up storage space. .

Metal folders from CIDAN Machinery Group offers convenient, flexible, and efficient .For flexible sheet metal processing, TRUMPF provides tailored machine tools and automation solutions, consulting, financing, and diverse services.MetalForming, LLC. is the largest and oldest distributor of sheet metal processing machines in North America, providing equipment, software, training, and consulting services that enable .Global presence, local response. For over 60 years, Salvagnini has been designing, producing and selling machine tools, industrial and flexible automation systems for sheet metal processing.

Tennsmith is recognized worldwide as a premier leader in the manuafacture of sheet metal fabricating machinery. We offer a full range of American-made sheet metal tools including .

various sheet metal processes

types of sheet metal process

What is Sheet Metal Processing?. At the heart of numerous industries, sheet metal processing stands as a foundational practice that allows for the creation of myriad products, tools, and structures. But what exactly does the term entail? .SHEET METAL PROCESSING MACHINES DEBURRING WITH A TIMESAVERS DEBURRING MACHINE Deburring is the removal of irregularities and sharp edges on metal products. They are often caused by machining work such as laser, water jet, punched or plasma cutting. Discover Timesavers' broad machine line for effective and efficient deburring.Sheet Metal Processing Solutions RVD Machinery have been supplying quality sheet working solutions to the industry for over 10 years. Recognised high quality components are carefully selected for all RVD metal working machinery to .Sri Sai Sheet Metal Machines India, Bangalore is a young and a dynamic company with team of committed professionals catering to sheet metal processing machinery for variety of applications. with their decades of expertise provide excellent Sales and Post Service. We are dedicated to deliver the world-class sheet metal machines of respected .

We have the widest variety of metal processing machines & equipment for leveling, deburring & coil line applications. From thin sheet metal to heavy plate! 24h customer hotline +49 . ARKU envisions the future of sheet metal processing in 2030, exploring climate change, AI, . READ MORE 11/04/2024 Event. EuroBLECH 2024 - Leveling. .In the field of industrial machinery, sheet metal processing plays a vital role. Sheet metal processing covers the entire process from design to finished product, involving many key links such as material selection, process determination, and precision control. This article will deeply explore the common process types and significant advantages .MYT(Shanghai) Machinery Equipment Co.,Ltd , based in Suzhou with Shanghai origins, leads in HVAC duct machines and sheet metal equipment. With 20 years’ experience, MYT invests heavily in R&D, surpassing 80% of industry rivals. Core products include HVAC duct machines, CNC press brakes, and fiber laser cutters.

Sourcing Guide for Sheet Metal Machines: China manufacturing industries are full of strong and consistent exporters. We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: laser cutting machine, metal cutting machine, fiber laser cutting machine.2. Deformation . Sheet metal deforming processes involve changing and processing sheet metal without cutting it. Bending is one of the most critical forming processes, and it can be done using a brake machine.A sheet metal company can use this tool to bend sheet metal into V, U, and channels up to 120 degrees.

types of sheet metal fabrication

Turret punching is a type of sheet metal processing that is controlled by a computer. CNC turret punching machines use a punch press to force a tool (called a punch) through a die to cut holes and shapes in precise locations. Turret punching can be used for many types of metal, from steel fabrication to aluminum manufacturing. The following is an introduction to some commonly used sheet metal processing equipment and their functions: 1.Laser Cutting Machine Function. Laser cutting machines use high-power laser beams to irradiate the workpiece, causing the material to be cut to rapidly melt, vaporize or ablate, and blowing away the melted material with the help of .

Folding Machines. KNUTH offers sheet metal folding machines with many different thickness capacities and lengths. From heavy duty manual folding machines to hydraulic folding machines with rear stops, segmented dies and high accuracy angular positioning, there are many sizes and capacities to choose from.SHEET METAL PROCESSING EQUIPMENT CATALOGUE AUTOMATION • MECHANICAL ENGINEERING • TECHNOLOGIES. LPRF (single purpose) . transverse cutting of coiled sheet metal with widths up to 1500 mm and a thickness from 0.2 to 3.0 mm with zinc or plastic coating and speed up to 90m/min.Sheet Metal Processing. The sheet metal fabrication machines make holes of various shapes in sheet metal, cut sheet metal, or bend sheet metal. Knives to bend sheet metal are called tools. . AMADA metal processing machines – proud parents of many products you use every day. Products Made with AMADA's Machines Contact us. CIDAN Machinery Inc 665 Hwy 74 S #350, Peachtree City, GA 30269, USA Phone: 770-692-7230

green metallic mesh fabric

3 Sorts of Sheet Metal Processing Equipment Details 2024/01/30. Integrating Automation with Rectangular Duct Machines for Enhanced Productivity 2024/05/11. Metal Shear Machines- Essential Tools for Precision Metal Cutting 2024/05/11. Understanding the Role and Function of Steel Strip Slitting Machines 3 Sorts of Sheet Metal Processing Equipment Details 2024/01/30. Maintenance Tips for Longevity of HVAC Duct Machines 2024/05/11. Innovations in Steel Strip Slitting Machine Design and Technology 2024/05/11. Improving Accuracy in Metal Fabrication with Laser Metal Shear MachinesHome > products > Machinery > Sheet metal processing > bench chamfering machine. BENCH CHAMFERING MACHINE. Art. 0560. Where to buy. add to favorites. Chamfer. 45° 0 - 5 mm. Speed. 2800 rpm. Motor. 230 V 50 Hz 0,25 kW. Table dimensions. 2 - 400 x 50 mm. Mill size. Ø 80 mm - Z 8. Insert. SPUN13P. Net weight. 21 kg. Packaging dimensions .Labh Group is a leading engineering, technology and consulting conglomerate, working closely with diversified industries spanning across food processing, agriculture, plastics, chemicals, metals, healthcare, packaging and other industries and business sectors offering complete turn-key solutions including advanced engineering, Industry 4.0 solutions, digital transformation .

The main function of these sheet metal machines is metal processing. Sheet Metal Machinery For High Precision. Sheet metal fabrication can be divided into various techniques such as bending, cutting, folding, etc. All this is achieved through the expertise of the manufacturers and the efficiency of the sheet metal equipment or tools they use. A hardened steel punch descends onto a metal sheet placed over a supporting die. The punch applies a significant amount of force, shearing through the metal and creating a burr-free hole or shape. Applications in Sheet Metal Processing. The versatility of metal sheet punching machines makes them indispensable in various industries, including:Machines to open holes and cut or weld thin sheets of metal (sheet metal) using a laser beam. Carbon dioxide lasers are often used for opening holes and cutting. A full line of oscillators is available for both fiber lasers (made in-house) and CO 2 lasers.

The press machine is widely used in the sheet metal processing industry and has powerful functions. The press machine can be used for cutting, bending, stamping, forming, and other metal processing. It is necessary to understand the function and use of the press machines before making a choice.Smartech Machinery is a top Chinese supplier of metal processing machinery. We specialize in roll forming machines, decoilers, coil upenders, and automated vertical storage system. Our high-tech metal processing machines are used in electrical, construction, and .

Sheet metal fabrication machines have been designed to achieve various metal processing effects on the metals & plates according to the input parameters instructed. Skip to content. Sheet Metal Fabrication Machinery Supplier. [email protected] +971 4 2368252 +971 4 .For the sheet metal processing industry of the future. Sheet metal is close to our hearts. That is why Bystronic supports you in modern sheet metal processing. We help you to optimize your production with laser cutting machines, tube lasers, press brakes, automation and suitable software. Your advantages. Save costs and reduce your CO2 emissions.

sheet metal process in manufacturing

This colorful illustration portrays how amazing a yellow brick house color is accented by dark roof colors. Here, dark shades of brown are found throughout the home’s brick exterior including brown wood framing, spouting, and carport.

metal sheet processing machines|sheet metal fabrication techniques