1.5hp franklin electric well pump control box troubleshooting Connect the SubDrive to a dry motor. If the motor goes through DC test and gives “underload” fault (1 fl ash every 2 seconds), the SubDrive is working properly.

Peel-Off Red Grease Pencils/China Marker/wax pencil for Glass, Cellophane, Vinyl, Metal, Etc. (12 Pencils)

0 · franklin well control box troubleshooting

1 · franklin well control box replacement

2 · franklin well control box readings

3 · franklin well control box overload problems

4 · franklin power control box troubleshooting

5 · franklin electric control box problems

6 · franklin 15 HP control box troubleshooting

7 · franklin 1.5 control box troubleshooting

Outdoor Electrical Box, Steel Junction Box 12 x 10 x 6'', NEMA 4X Electrical Enclosure Box IP66 Waterproof & Dustproof, Universal Electrical Project Box with Lock & Mounting Plate

Measure Voltage at Control Panel. Measure voltage at L1 and L2 in the Control Panel. The reading should be +/- 10% of motor rating. Check Overloads. Set Ohmmeter to . Link to troubleshooting video: https://youtu.be/KEM11xTWGH8Have a question? You can liv. Here are the readings I received on my pump tests.1.5HP Motor: Bl: 12.73A Max; Y: 13.27A Max; R: 3.62A Max 1.35A Running Pump Ohm Check: Y&Bl: 2.0 Ohms; Y&R: 9.0 . Pump is 1.5hp Franklin single phase 3-wire. Control box diagram below. Issue: When power sent to control box the pump pulls 41a (about 31a on red/run and 11a on yel/start) .

Sounds like the control box problem is because of a short somewhere between the control box and the pump or even the pump it's self. A qualified and NGWA certified well or .

Connect the SubDrive to a dry motor. If the motor goes through DC test and gives “underload” fault (1 fl ash every 2 seconds), the SubDrive is working properly.

Dry well protection occurs when pump suction is broken. Deadhead conditions may not always be detected due to variation in pump load characteristics Installation Instructions 1. Remove the .

Full troubleshooting guide can be found in the Franklin Electric AIM Manual: https://www.rcworst.com/Shared/content/mfr/franklin_electric/docs/franklinsubmer. Measure Voltage at Control Panel. Measure voltage at L1 and L2 in the Control Panel. The reading should be +/- 10% of motor rating. Check Overloads. Set Ohmmeter to lowest ohm setting and test each of the overloads by touching the solder points inside the box.

Link to troubleshooting video: https://youtu.be/KEM11xTWGH8Have a question? You can liv. Here are the readings I received on my pump tests.1.5HP Motor: Bl: 12.73A Max; Y: 13.27A Max; R: 3.62A Max 1.35A Running Pump Ohm Check: Y&Bl: 2.0 Ohms; Y&R: 9.0 Ohms The pump is ohming with zero grounds detected.

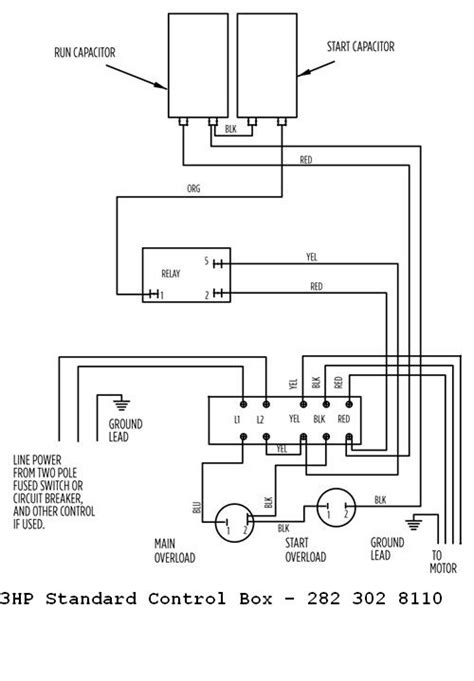

Pump is 1.5hp Franklin single phase 3-wire. Control box diagram below. Issue: When power sent to control box the pump pulls 41a (about 31a on red/run and 11a on yel/start) and pump does not run. After a little bit main overload breaker on control box trips. Steps done: - Pump windings measure correct on ohmmeter.

Sounds like the control box problem is because of a short somewhere between the control box and the pump or even the pump it's self. A qualified and NGWA certified well or pump man can and will check that before pulling the pump.Connect the SubDrive to a dry motor. If the motor goes through DC test and gives “underload” fault (1 fl ash every 2 seconds), the SubDrive is working properly.Dry well protection occurs when pump suction is broken. Deadhead conditions may not always be detected due to variation in pump load characteristics Installation Instructions 1. Remove the cover from the Pumptec. 2. If you will be running a 1.5HP motor, move the circuit board jumper to the 1.5HP position as shown in Figure 1. Underload Trip .

On-site Field Service: When you work with Franklin Electric, you have access to the industry’s leading Technical Support professionals and Field Service Engineers located throughout the nation to assist you with on-site troubleshooting and other service needs.Franklin Electric submersible control boxes are designed and optimized specifically for Franklin three-wire, single-phase motors rated 1/3 to 15 hp. Quick Disconnect (QD) boxes make trouble shooting simple by automatically disconnecting the control components from .Full troubleshooting guide can be found in the Franklin Electric AIM Manual: https://www.rcworst.com/Shared/content/mfr/franklin_electric/docs/franklinsubmer.

Measure Voltage at Control Panel. Measure voltage at L1 and L2 in the Control Panel. The reading should be +/- 10% of motor rating. Check Overloads. Set Ohmmeter to lowest ohm setting and test each of the overloads by touching the solder points inside the box. Link to troubleshooting video: https://youtu.be/KEM11xTWGH8Have a question? You can liv. Here are the readings I received on my pump tests.1.5HP Motor: Bl: 12.73A Max; Y: 13.27A Max; R: 3.62A Max 1.35A Running Pump Ohm Check: Y&Bl: 2.0 Ohms; Y&R: 9.0 Ohms The pump is ohming with zero grounds detected. Pump is 1.5hp Franklin single phase 3-wire. Control box diagram below. Issue: When power sent to control box the pump pulls 41a (about 31a on red/run and 11a on yel/start) and pump does not run. After a little bit main overload breaker on control box trips. Steps done: - Pump windings measure correct on ohmmeter.

Sounds like the control box problem is because of a short somewhere between the control box and the pump or even the pump it's self. A qualified and NGWA certified well or pump man can and will check that before pulling the pump.Connect the SubDrive to a dry motor. If the motor goes through DC test and gives “underload” fault (1 fl ash every 2 seconds), the SubDrive is working properly.Dry well protection occurs when pump suction is broken. Deadhead conditions may not always be detected due to variation in pump load characteristics Installation Instructions 1. Remove the cover from the Pumptec. 2. If you will be running a 1.5HP motor, move the circuit board jumper to the 1.5HP position as shown in Figure 1. Underload Trip .On-site Field Service: When you work with Franklin Electric, you have access to the industry’s leading Technical Support professionals and Field Service Engineers located throughout the nation to assist you with on-site troubleshooting and other service needs.

metal fabricators bath

$57.99

1.5hp franklin electric well pump control box troubleshooting|franklin well control box readings