what is steel box girder In 1919, Major Gifford Martel was appointed head of the Experimental Bridging Establishment at Christchurch, Hampshire, which researched the possibilities of using tanks for battlefield engineering purposes such as bridge-laying and mine-clearing. Here he continued trials on modified Mark V tanks. The bridging component involved an assault bridge, designed by Major Charles Inglis RE, the Canal Lock Bridge, which had sufficient length to span a canal lock. Major . $111.00

0 · tubular design vs girder

1 · steel box girder design example

2 · steel box girder design

3 · single cell box girder

4 · prestressed concrete box girder

5 · prestressed box girder

6 · maximum length of steel girder

7 · designing a steel girder beam

So, when it comes to a box spring vs. slats, which one should you choose? In this article, we’ll cover the differences between these products, who they’ll work best for and why, and other important questions so you can .

In 1919, Major Gifford Martel was appointed head of the Experimental Bridging Establishment at Christchurch, Hampshire, which researched the possibilities of using tanks for battlefield engineering purposes such as bridge-laying and mine-clearing. Here he continued trials on modified Mark V tanks. The bridging component involved an assault bridge, designed by Major Charles Inglis RE, the Canal Lock Bridge, which had sufficient length to span a canal lock. Major .

It is a bridge in which the main beams comprise girders in the shape of a hollow box (rectangular or trapezoidal shape). The box girder normally comprises either prestressed concrete, structural steel, or a composite of steel and reinforced .

Box girder bridge's design offers high torsional stiffness and strength, making it ideal for long spans, curves, and complex alignments in modern infrastructure. A box girder bridge is a type of bridge where the .A box girder bridge is one in which the principal structural element is one or more closed cells, acting in bending. Box girders are used for highway bridges, railway bridges and footbridges – .Box girders have become a prominent element in the con struction of major river crossings, highway interchanges, and transit systems. These types of structural elements are particularly . A box girder is essentially a rectangular or trapezoidal hollow beam, typically made from steel, concrete, or a combination of both materials. The design of box girders allows for .

tubular design vs girder

Composite box girder construction offers an attractive and economic form of construction for medium span highway bridges. The torsional properties of the closed section are often .

Box girders are used for footbridges curved in plan, bridges with longer spans and cable-stayed bridges with a single plane of stays. All-steel construction is typically used, for lightness. A .A steel girder bridge is a type of bridge that uses steel girders as the primary support structure. Girders are horizontal beams that span between two abutments or piers, carrying the weight of .

The box girder normally comprises either prestressed concrete, structural steel, or a composite of steel and reinforced concrete. A box girder is formed when two web plates are joined by a common flange at both the top and the bottom. The .3 BEHAVIOUR OF BOX GIRDER BRIDGES 4 3.1 General 4 3.2 Bending, torsion and distortion 4 3.3 Torsion and torsional warping 6 3.4 Distortion 7 3.5 Stiffened compression flanges 11 3.6 Shear lag 11 3.7 Support of box girders 11 4 INITIAL DESIGN 13 4.1 General 13 4.2 Loadings 14 4.3 Choice of a box girder form 14

steel box girder design example

The PSC Segmental Box Girder bridge design starts with the Conceptual Design, where the configuration and span arrangement of the bridge are determined. Longitudinal Design is then the verification of the sections at .

There are two primary types of bridge girders commonly used: Profile Girders and Box Girders. A profile girder is a steel beam that can be purchased pre-manufactured for various applications and is found commercially available in a set standard of sizes. Depending on the live load capacity and crane configuration design, a girder is selected to . Double girder design of overhead crane. The most common form of girder structureutilized by overhead cranes is the box-type girder structrue. The upper and lower cover plates, as well as two vertical cover plates, make up the box crane girder, which is made up of closed box-shaped section constructions. Beams are classified as I, T, and C beams depending on how their cross sections are shaped. Typically, a steel beam is referred to as a girder. The most typical kind of girders used in bridge construction is I-beam girders. The construction of elevated bridges and road flyovers primarily uses box girders. The functionality of Beam Vs. GirderA box girder is a type of structural beam used in construction that is very often made of steel, though in the past iron was commonly used for construction.

steel box girder design

Box girders offer stronger construction, especially for bridges that must have a curve to them. They are commonly used in freeway overpasses. The Oakland/San Francisco Bay Bridge is a box girder bridge. The girders of the bridge are usually made from prefabricated steel. This means that the girders are created in a factory, and then brought to .A steel girder bridge is a type of bridge that uses steel girders as the primary support structure. Girders are horizontal beams that span between two abutments or piers, carrying the weight of the bridge deck, which is the roadway or pedestrian path that sits on top of the girders.

In November 1971 a steel box-girder bridge across the River Rhine near Koblenz in Germany collapsed killing 12 people. Investigating the disasters The British government responded by setting up the Merrison Committee of Inquiry. It was tasked with investigating the design and construction methods of box-girder bridges. It was also asked to make . 2.5 - Box Girders for Straddle Bents - Flanges, s, Stiffeners, Bearings, Field Splices, Flange- to- Welding. . Suggest dapping if difference in approach span depth and steel girder depth is >1.5’ for aesthetic reason (Will remain in document).

The frequency of use of steel box girders has increased in the state of Texas and throughout the United States over the past 10 years. Some of the advantages of the structural shape that have led to the increased utilization include improved aesthetic, maintenance, and structural benefits. .

Box girder bridges No. 1.08 SCI P185 Guidance notes on best practice in steel bridge construction 1.08/1 GN107R3.doc Revision 3 Scope This Guidance Note gives an overview of the main design issues for steel box girders in short and medium span bridge schemes. SCI-publication P140 (Ref 1) gives a more exten-sive treatment of steel box girder design.Precast, pretensioned concrete box girders (precast box girders) are typically used for relatively short span structures with limited or inadequate temporary clearance for a falsework, as discussed in Section 5.3.1. Placed sideby-side, the top flange can serve - as the driving surface, which makes them ideal for Accelerated Bridge Construction . He demonstrated how to use Midas civil to model curved steel box girder bridges as well as go over the procedure he followed to perform load rating. Last but not least, he discussed the modeling of end diaphragms with plate .A structural girder is a construction support beam. It is a structure’s main horizontal support that supports smaller beams. Girders typically have an I-beam cross section, although they can also have a box, Z, or other shape. Bridge .

girder bridges have become widespread and are commonly used at locations that require complex geometries and have limited right-of-way, such as urban interchanges. Some of the important issues that differentiate curved steel girders from their straight counterparts include the .5.27 Curved Cast-In-Place Prestressed Box Girders 3 . Figure 5.27.5.1.1 Lateral Tendon Force . The need for “Detail A” is a function of the concrete tensile stress adjacent to the tendons. . determined by using an equivalent area of steel. Stirrup spacing requirements were determined using a combination of three different force A box girder concrete beam is a type of beam that is made up of a hollow box section. The box section is typically made of concrete, but it can also be made of steel or a composite material. The box section is designed to provide strength and rigidity, and the extended wings help distribute load. Concrete Box Girders are available a typical width of 12’ (3.66 m), . : The temperature effect has a great impact on the reasonable completion state of the steel box girder. The relevant research has an important role in promoting the design, construction and operation and maintenance of the steel box girder. Firstly, the effects of uniform temperature difference and gradient temperature difference are analyzed, and three gradient .

single cell box girder

Most studies of thermal actions on bridges have been devoted to concrete structures. In this paper, we focus our analysis on steel box girder bridges. The statistical analysis is based on data collected over a three-year period by temperature gauges placed in appropriate places on the Normandy Bridge, France. Temperature–time series are generally known to . The box girder consists of concrete, steel or a combination of both. Most of modern elevated structures are built on the basis of the box grider bridge. The spanning of bridges started with simple slabs. As the spans increased, the design depth of slab is also increased. It is known that material near centre of gravity contributes very little .

A box girder bridge, or box section bridge, is a bridge in which the main beam consists of girders in the shape of a hollow box. Box girders typically consist of prestressed concrete, structural steel, or a mixture of steel and reinforced concrete. The box is .

The steel girder design criteria are obtained from Figures 3-1 through 3-3 (shown below), . Some of the design principles for this design example are presented in "tip boxes." Design computations for a bolted field splice are presented in Design Step 4. Design computations and principles for shear connectors, bearing stiffeners, welded .A steel I-beam often acts as a girder beam in homes and many other types of structures. It’s called an I-beam because the end profile of the beam is shaped like an uppercase letter “I”. . A popular term for these girder beams is box beams. Box – or girder – beams are very common in home construction because they are fairly light . Box Girders. Box girders feature a hollow, rectangular cross-section, which provides a high strength-to-weight ratio and excellent torsional resistance. . Steel girders are often fabricated in controlled environments, ensuring precision and quality. They can be easily customized to meet specific design requirements and are compatible with .

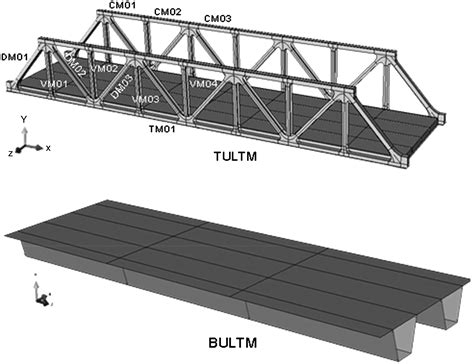

single steel box girder, and 3) twin steel box girders, as shown in Figure 4. Each type of superstructure is supportable by single-column piers. The twin steel box girders were eventually selected for the flyover bridge and the Issaquah Creek Crossing Bridge because of the following relative advantages:

prestressed concrete box girder

prestressed box girder

We offer 3-axis CNC and 5-axis CNC machining, with 150 years of woodwork expertise. From planters to intricate, beautiful furniture. We can help you to create your vision.

what is steel box girder|single cell box girder