best flux cored wire for sheet metal Gasless flux core wire is used to generate its own shielding gas for a weld. This prevents impurities from contaminating the weld and because there’s no need for gas – it makes for a more portable welding solution than standard solid wire welding might. This approach to welding is also valuable in windy, . See more Visit the business profile for T/A West Creek Sheet Metal in West Creek , NJ . Discover businesses with the D&B Business Directory at DandB.com.

0 · how to weld with flux core wire

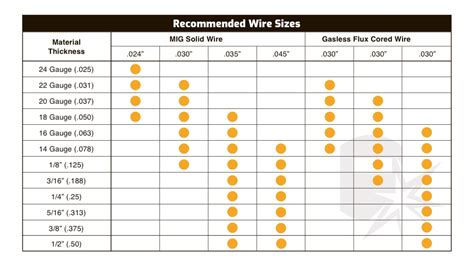

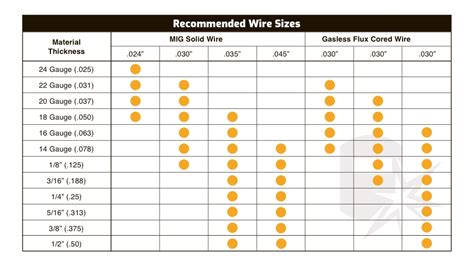

1 · flux core wire size chart

2 · flux core welding wire chart

3 · flux core welding for dummies

4 · best flux core wire welder

5 · best flux core wire for mild steel

6 · best flux core wire

7 · best flux core only welder

If you own an older home (built before 1990), you might have one of these outdated main electric panels/boxes hiding in your home. And these outdated panels don’t just make you uncool like a pair of outdated bell-bottoms might.

Gasless flux core wire is used to generate its own shielding gas for a weld. This prevents impurities from contaminating the weld and because there’s no need for gas – it makes for a more portable welding solution than standard solid wire welding might. This approach to welding is also valuable in windy, . See moreYes, it’s fine to use flux core wire in a MIG welder and there’s no need to buy a separate flux core welder. As I touched on previously, this can . See more

No. Though you may find some chancers on the Internet selling “flux cored aluminum wire” when you read the small print – you’ll find that it says “we . See more

Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple ..90

how to weld with flux core wire

flux core wire size chart

‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030 ..99

This is the ultimate buyer’s guide to the best Flux Core Welding Wire. We recommend using YESWELDER Flux Core Mig Wire, Mild Steel E71TGS.035 .INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian . Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod . Flux-core wire is the best material to use when welding dirty or rusty steel. It also makes welding outdoors possible. The best flux-core wire improves the tensile strength of the weld and helps to bond metal to metal in difficult .

flux core welding wire chart

My choice of the best flux-cored wire for mild steel is the Forney 42300. I found that no matter what the condition of the material was that it produced excellent quality welds. My claims are supported by the extraordinary number of positive reviews on the internet. Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple pass welding. It’s good for jobs like sheet metal stitch welding or .

Are you looking for the best flux core wire for sheet metal? If so, you have come to the right place. A flux cored wire is soft and malleable, meaning that it can be easily bent and molded into complex shapes without breaking or buckling. ‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030-inch wire and the best flux core wire for mild steel. This is the ultimate buyer’s guide to the best Flux Core Welding Wire. We recommend using YESWELDER Flux Core Mig Wire, Mild Steel E71TGS.035-Diameter, 10-Pound Spool, as it is a high-quality product.INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian manufactured wire is reputed for its versatility. This wire is perfect for all welders; from beginners to advanced professionals. It does good welding like solid wires.

Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod coatings, the core of the wire contains a flux agent that substitutes for the tank of shielding gas. Flux-core wire is the best material to use when welding dirty or rusty steel. It also makes welding outdoors possible. The best flux-core wire improves the tensile strength of the weld and helps to bond metal to metal in difficult circumstances. Welding thin sheet metal with flux core is a great way to produce complex, detailed shapes quickly and efficiently. In this article, you will learn about flux core welding and get tips for successfully using. Read on to discover why these wires are the top picks. And choose the perfect one for you and your key welding projects. 1. INE INETUB BA71TGS Mild Steel Flux Cored Wire Insiders View. 2. Blue Demon E71TGS Mild Steel Flux Cored Wire Insiders View. 3. Lincoln Electric Inner Shield NR-211-MP Mild Steel Flux Cored Wire Insiders View. 4.

can sheet metal be welded with 220 mig welder

My choice of the best flux-cored wire for mild steel is the Forney 42300. I found that no matter what the condition of the material was that it produced excellent quality welds. My claims are supported by the extraordinary number of positive reviews on the internet. Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple pass welding. It’s good for jobs like sheet metal stitch welding or .

Are you looking for the best flux core wire for sheet metal? If so, you have come to the right place. A flux cored wire is soft and malleable, meaning that it can be easily bent and molded into complex shapes without breaking or buckling. ‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030-inch wire and the best flux core wire for mild steel.

This is the ultimate buyer’s guide to the best Flux Core Welding Wire. We recommend using YESWELDER Flux Core Mig Wire, Mild Steel E71TGS.035-Diameter, 10-Pound Spool, as it is a high-quality product.INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian manufactured wire is reputed for its versatility. This wire is perfect for all welders; from beginners to advanced professionals. It does good welding like solid wires. Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod coatings, the core of the wire contains a flux agent that substitutes for the tank of shielding gas. Flux-core wire is the best material to use when welding dirty or rusty steel. It also makes welding outdoors possible. The best flux-core wire improves the tensile strength of the weld and helps to bond metal to metal in difficult circumstances.

can osb be cnc machined

Welding thin sheet metal with flux core is a great way to produce complex, detailed shapes quickly and efficiently. In this article, you will learn about flux core welding and get tips for successfully using.

The surface components are transformers, motor controllers, junction box and wellhead. The wellhead accommodates the passage of the power cable from the surface to the wellbore. The main down-hole components are the motor, seal, pump, and cable.

best flux cored wire for sheet metal|how to weld with flux core wire