cnc machine basic programming pdf The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming .

range of requirements for buildings. Specific areas within Title 24 identify certain requirements for solar PV installations such as the California Electrical Code, the California Building Code, and the California Residential Code (which applies to resid.

0 · peter smid cnc programming handbook PDF

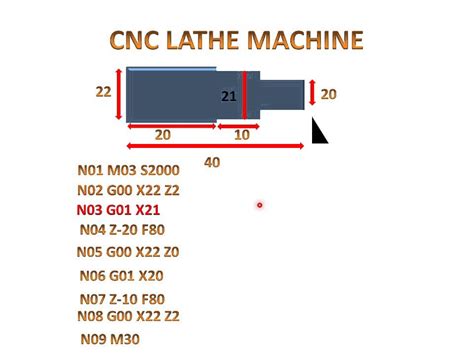

1 · cnc turning program examples PDF

2 · cnc turning cycle program PDF

3 · cnc turn mill programming PDF

4 · cnc programming for dummies PDF

5 · cnc programming PDF free download

6 · cnc machine books free download PDF

7 · cnc g code and m list PDF

Handcrafted and locally sourced right here in the U.S.A., we create luxury steel doors and partitions that stand the test of time. As an award-winning team of fabricators and engineers, we see every project as a unique opportunity to blend art and function.

This course describes the basic knowledge of CNC machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has . Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our .The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different .

- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console .

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming .Parts of a CNC Program • Safe-start: clears machine for new operation • Material removal: performs operations • Program ending: safely positions tool & axes out of the way

This workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by .CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically .Computer Numerical Controls (CNC) govern the movement of machine tools. Machine tools can be generally divided into two basic groups Turning and Milling. There are several other .This course describes the basic knowledge of CNC machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .

peter smid cnc programming handbook PDF

Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry. Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.

- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console of the machine directly. These are all valuable skills that .The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationParts of a CNC Program • Safe-start: clears machine for new operation • Material removal: performs operations • Program ending: safely positions tool & axes out of the wayThis workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

Computer Numerical Controls (CNC) govern the movement of machine tools. Machine tools can be generally divided into two basic groups Turning and Milling. There are several other machine tool categories, but for simplicity, we will concentrate on turning and milling.

This course describes the basic knowledge of CNC machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .Numerical control (NC) enables an operator to communicate with machine tools through a series of numbers and symbols. NC which quickly became Computer Numerical Control (CNC) has brought tremendous changes to the metalworking industry.

lund specialty steel tool boxes

Get up to speed on CNC programming with CNCCookbook's PDF guide. Learn about machine codes, G-code, and more with our comprehensive tutorial.The first sections of the manual take you through the very basics of what a CNC Mill is and what operations it can do, the basics of how the machine works, what G - Code is, the different types of tools that can be used and other practical things you need to know. This is followed by an overview of the actual TORMACH CNC Mill.- Create quick and dirty g-code programs that allow you to get on with machining faster without having to sit down with your CAD/CAM. - Develop a greater facility for working at the console of the machine directly. These are all valuable skills that .

lund steel job site storage box

The Programming Manual "Fundamentals" is intended for use by skilled machine operators with the appropriate expertise in drilling, milling and turning operations. Simple programming examples are used to explain the commands and statements, which are also defined according to DIN 66025. 2. Work preparationParts of a CNC Program • Safe-start: clears machine for new operation • Material removal: performs operations • Program ending: safely positions tool & axes out of the wayThis workbook provides basic programming principles necessary to begin programming the HAAS C.N.C. Lathe. In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.

CNC Machining . Intro to CNC Machining • CNC stands for computer numeric controlled. It refers to any machine tool (i.e. mill, lathe, drill press, etc.) which uses a computer to electronically control the motion of one or more axes on the machine. • The development of NC machine tools started from a task supported

cnc turning program examples PDF

cnc turning cycle program PDF

MIG welding is the preferred method for most automotive bodywork, and since sheet metal is the thinnest of metals, a large, expensive MIG unit is usually not required. The majority of sheet metal repair that I've done was with a 90-amp, 110-volt welder.

cnc machine basic programming pdf|cnc turning cycle program PDF