strength of bent sheet metal vs welded Whether you’re dealing with corrugated sheet metal, decorative sheet metal, or functional sheet metal for industrial applications, our guide, complete with a sheet metal gauge chart, aims to enrich your knowledge and foster a better . WESTERN METAL FABRICATORS, 105 Missouri St, San Francisco, CA 94107, 4 Photos, Mon - 9:00 am - 5:00 pm, Tue - 9:00 am - 5:00 pm, Wed - 9:00 am - 5:00 pm, Thu - 9:00 am - 5:00 pm, Fri - 9:00 am - 5:00 pm, Sat - Closed, Sun - Closed

0 · sheet metal bending tolerances

1 · sheet metal bending strength

2 · sheet metal bending standards

3 · sheet metal bending specifications

4 · sheet metal bending pros and cons

5 · sheet metal bending disadvantages

6 · sheet metal bend strength chart

7 · advantages of sheet metal bending

Western Spiral Pipe & Fittings Inc. 1890 S 3850 W, Salt Lake City, UT 84104. 1-801-908-0668

The following is a design comparison of structural steel sections versus formed and welded steel plate sections including a comparison of strength in bending.

Re: Strength of bent steel vs welded. Bending would be a lot easier and it would be stronger than welding. Having said that welding might be more than adequate depending on .

Sheet metal bending has distinct advantages over alternative sheet metal fabrication processes, including higher output, lower cost and high flexibility in design. It also removes many .Whether you’re dealing with corrugated sheet metal, decorative sheet metal, or functional sheet metal for industrial applications, our guide, complete with a sheet metal gauge chart, aims to enrich your knowledge and foster a better . If you're only looking at strength, then a weld will be stronger than a bend in mild steel assuming the electrode has a higher tensile strength than the base metal. Here, we’ll explore the sheet metal welding methods we use in our shop and explain what to expect from each one. Table of Contents. 1 Spot Welding. 1.1 Considerations for spot welding. 2 Tack Welding. 2.1 .

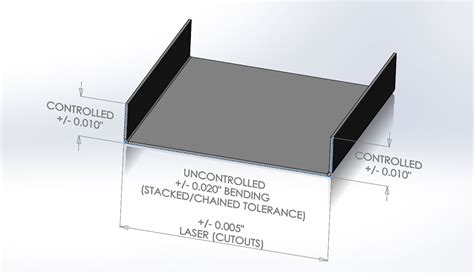

sheet metal bending tolerances

In Machinery’s Handbook, the K-factor for mild cold-rolled steel with 60,000-PSI tensile strength is 0.446 inch. This K-factor is applied as an average value for most bend allowance calculations. There are other values for .

The maximum stress that a cross section experiences when a load is applied between two points of a specimen is called the bend strength. The unit of measurement is N/mm 2 or MPa, and it is represented by the symbol σbb. . This calculator covers the weld strength calculation for different types of welding joints. Read on to understand what is a fillet weld or a butt joint and their strength calculations.

If you continuously weld, then you fight warping the steel with heat. For a 40’ trailer, you would end up welding hundreds of feet of steel—just for the side rails. Instead, side rails are stitch welded. Stitch welding means that instead of . Assuming there are no weld defects like voids or undercut, the welded piece will still have a large microstructure and strength transition from the base metal, through a coarse grain/"weakened" HAZ, to a higher strength weld metal. The cold bend should have less of differential in microstructure and strength between the base metal and the .

sheet metal bending strength

The metal in question would be hot rolled 3/16ths or 1/4" sheet, the bent portion being about 3/8ths to 1/2 wide. Which is to say that the narrowest area of the of the whole thing is where the bend is happening. I feel like I have 3 main options: Cold bend Hot bend make two pieces and weld them together.

The lap joints can either be single transverse, i.e., single weld line, double transverse, parallel, or combination of these welds. Similarly, the butt joints are either single or double-sided.The strength of the weld joint depends on either tensile or shear stress, or a combination of both.The direction of the weld joints decides the design stress (see stress . The queation is to vague.In my experiance in the sign trade I worked with copper, brass,aluminum and steel.I've found that some alloys bend very well,while others break.I had these results with all four metals.I'm not as experianced welding these as others on this site but I am sure diferant alloys of the same metal would have unique welding qualitys.Bending sheet . Since sheet metal is melted at the welding position, it might damage the various properties of parts around the heat-affected zone. 2. Stress generation. Simultaneous heating and cooling of sheet metal at the welding position creates undesirable residual stress, which might lower the load-bearing capacity. 3. High vibration Table of Contents. 1 Common Weld Joints in Custom Sheet Metal Fabrication. 1.1 Open corner weld joint ; 1.2 Closed corner weld joint ; 1.3 Spot-Weld Flange Joint; 2 Consult Your Sheet Metal Fabricator about the Optimal Joining Method. 2.1 Joint and weld solutions; 2.2 Other joining solutions; 2.3 Closed corner weld joint ; 2.4 Spot-Weld Flange Joint; 3 Consult Your .

sheet metal bending standards

Sheet Metal: While sheet metal fabrication involves various processes like cutting, bending, and welding, it generally consumes less energy than plate metal fabrication due to the thinner material and simpler processes involved. However, the use of coatings and finishes can introduce additional environmental concerns.Cast metal in right angles would be stronger than metal that has been bent, since it is 'unbent'. However, if the bent metal was bent while it was white/red hot it would be less weak since it's 'strength' is when it cools and becomes hardened. So in order of strength; cast metal,metal bent while semi molten, cooled bent metal.

However, in actual production, welding materials are often selected based on the strength of the deposited metal, which is not equivalent to the actual weld strength. The deposited metal is not equivalent to the weld metal, especially when welding materials are used for low-alloy high-strength steel, where the strength of the weld metal is . Explore 7 key techniques to enhance sheet metal parts' strength and durability, from material selection to advanced bending methods. . Techniques like laser cutting and welding add immense strength to sheet metal parts. These methods create strong, permanent joints, essential for parts that require closed hems or complex structural grooved .

2 Approved Sheet Metal’s Proven Approach to Corner Construction; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Metal Fabrication Corner Construction FAQ. 4.0.1 Why is proper corner construction crucial in sheet metal fabrications? 4.0.2 How does Approved Sheet Metal ensure high-quality corners in every fabrication?

Equal strength. There’s a common misconception that welding is stronger than bolting, but that simply isn’t true. Bolting is just as strong as welding—and can be stronger in some situations. The strength of a weld is largely determined by the expertise of the welder. Metal fabrication is a profession that requires several years of training and apprenticeship to master the art. Metal fabrication involves welding and riveting, and most people find difficulties in differentiating between riveting vs welding. There are several factors to consider when choosing between rivets vs welding.Now, let’s dive a little deeper into the actual welding process for these two types of metal. And let me tell you, it’s a whole different ballgame when it comes to sheet metal vs. plate metal. With sheet metal, you’ve gotta be super careful .Issues such as these usually aren’t present with bending. Bent sheet metal parts are often ready to go, straight from production. Less Weight – With sheet metal bending techniques, stiffness and strength can often be achieved in parts .

after it is cooled off, i "bend" it, as in flop around like a flat spring in my hands (i didn't mean bend as in fold it in half to permanently deform it). i am imagining the following experiment: take two 2" x 36" strips of 1/16" AL sheet 6061-T6. anneal one sheet and leave the other at T6 temper. Table of Contents. 1 Key Differences Between 6061-T6 vs. 5052-H32 Aluminum. 1.1 Choose 6061-T6 for machined parts; 1.2 Choose 5052-H32 for fabricated parts; 2 Custom Aluminum Fabrication at Approved Sheet Metal. 2.1 When you need to see for yourself.; 2.2 When you’ve read that 6061-T6 is “easy to form.”; 2.3 When a material swap isn’t possible.; . Learn how to calculate the bending strength of section steel, including the formulas, factors, and applications. . The connection weld is mainly used to resist bending shear, . My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. . Yield strength refers to the stress of a metal sample during the stretching process when the load is no longer increasing but the sample continues to deform. The unit of measurement is N/mm 2 or MPa, and it is represented by the symbol σs. The yield strength is the pressure value at the yield point. For materials that do not exhibit an obvious yield point, the .

sheet metal bending specifications

Table of Contents. 1 Spot Weld vs. Seam Weld; 2 7 Things to Know About Spot Welding ; 3 Sheet Metal Part Design for Manufacturing Tip. 3.1 CORNERS AND WELDING; 4 Spot Welding FAQ. 4.0.1 What is the difference between spot welding and seam welding, and when should I choose one over the other?; 4.0.2 What is plug welding, and when should I .Due to the high thermal conductivity, aluminum is harder to weld. Finally, aluminum is not suitable in culinary applications as it reacts with and changes the color and flavor of food products. Typical uses: Weight reduction (1/2 the strength of steel at 1/3 the weight), aircraft bodies

Metal bending maintains the metal’s structural integrity and strength, making it a preferred method for transforming metal. Welding makes the metal weaker in the heat-affected zone. So, if strength is a prerequisite for the project, mental bending must be chosen.

Additionally, bending sheet metal can help improve the overall strength and durability of your materials, making them more resistant to bending, breaking, or warping. Bending Sheet Metal vs. Welding . While welding is another common method for joining and shaping sheet metal, it’s not always the best option. Bending sheet metal offers several . 5052 aluminum sheet is popular because it is one of the most versatile aluminum alloys. It is strong enough for fuel tanks, but adaptable enough for utensils. Why is 5052 such a popular choice with our customers? Here’s the in-depth answer. A General Introduction to 5052 Aluminum Sheet. Among 5052 aluminum’s benefits are good weldability, very good resistance . Tube bending, the art of permanently shaping tubes, holds the key. This guide delves into the world of metal tube bending, exploring its techniques, considerations, and applications. Understanding the Bend: Types and Terminology. Form-bound vs. Freeform: Tube bending methods fall into two broad categories: form-bound and freeform.

Square Tubing: Manufacturing for Strength. To alleviate any concerns with square tube strength, turn to how it’s manufactured. Though its shape can lead to some issues with strength, square tubes can be made to more than withstand the demands of your project. Steel tubing of any shape is made in one of two ways: hot or cold forming.

sheet metal bending pros and cons

sheet metal bending disadvantages

If you install a box in a wet location, for example, you must use a box, fittings, and installation methods that are acceptable for wet locations. Fortunately, Art. 314 helps you select the right outlet, device, and junction boxes — and size them properly.

strength of bent sheet metal vs welded|sheet metal bending tolerances