lance in sheet metal features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections. Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations.

0 · thinning in sheet metal forming

1 · sheet metal lance stamping

2 · press forming of sheet metal

3 · lancing process in sheet metal

4 · lancing operation in sheet metal

5 · lance punch dies

6 · how to joggle sheet metal

7 · half shear sheet metal

Shop DryConn Underground/Waterproof Wire Connectors Aqua (500-Pack) in the Wire Connectors department at Lowe's.com. Waterproof your outdoor splices with the DryConn medium, aqua/red wire connector. This quality one-step connector is filled with a .

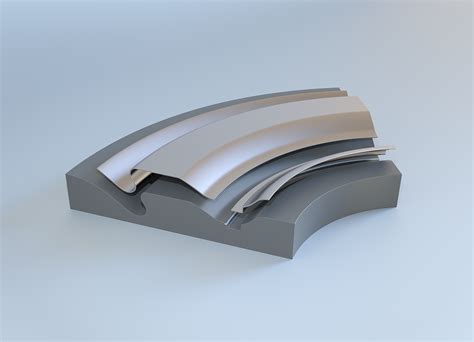

A Lance and Form is a tool that both cuts (lances) and forms sheet metal. They are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear . Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in punching machines today. More complex forming tools include those that produce . In this video, I am going to explain about creating "Bridge Lance" feature in Solidworks, which is Sheet Metal Stamping Feature and manufacture with Lacing . The Forming Tool model is separate from the workpiece model being designed. An example for a bridge lance tool is shown in Figure 7a. The Forming Tool model represents the .

features into a flat sheet. Some of the options are counter sinks, offsets, card guides, embosses, draws, wipe forms, part markings, lettering, lances, half-shears, and weld projections.

Assembling sheet metal parts with fasteners, welds and clips adds extra time and cost. Watch this video to see how you can punch fasteners directly into components using common forming .FORMING TOOLS. 1)HALF SHEAR (SHEAR BUTTON) 2)EMBOSS (DIMPLE) 3)COUNTERSINK FOR COUNTERSUNK SCREW (CHAMFERING) 4)COUNTERSINK. 5)COUNTERSINK BURRING. 6)ONE PITCH .UniPunch designs a wide variety of lance & form tooling. The size, shape and depth of the lance are required for quotation. Shown here is a pierce and form operation typically for air venting .

TECHNICAL GUIDE. FORMING TOOLS. 14) LANCE (Z-BENDING) OUTLINE OF FORMING. Forming process of lance like Z-shape. Used for hook, positioning and stopper. NOTE. 1) Please indicate the each dimension when you order. .

For full video, please click the link below https://youtu.be/p9icrJ5T2MUA sheet metal part has the Sheet-Metal1 feature in the FeatureManager design tree. The part on which you insert the forming tool is called the target part. You can create your own forming tools using many of the same steps you use to create any SOLIDWORKS part.Assembling sheet metal parts with fasteners, welds and clips adds extra time and cost. Watch this video to see how you can punch fasteners directly into components using common forming tools. . Lance and Forms are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear tabs, wire . Columnist Gerald Davis continues a discussion of 3-D CAD and precision sheet metal manufacturing in Part IV of a four-part series. In this installment he focuses on the merits and demerits of hems, jogs, and forming tools. . An example for a bridge lance tool is shown in Figure 7a. The Forming Tool model represents the interior of the feature .

All you have to do is create a sheet metal part (attached), do the usual thing of creating a sketch point for the lance, adjust the placement angle and any parameters and its done.-- Dennis Jeffrey, Autodesk Inventor Certified Expert Autodesk Manufacturing Implementation Certified Expert. 260-399-6615 Instructor/Author/Sr. App Engr.What is Precision Sheet Metal Fabrication? The basic metal fabrication process forms, shapes and joins metal together through the removal or . Bridge Lance Lance/ Share Form. Common Metal Stamping Features & Manufacturing Considerations. Common Metal Stamping Features &Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - Embosses and Offsets – Emboss and offset dimensions should be to the same side of the material unless the overall height is critical. Lance and forms (tabs, bridges, knockouts, cable ties) and extrusions are among the advanced class of forms being produced in punching machines today. . Louver types abound, but when it comes to sheet metal fabrication, closed- and open-end louvers are probably the most popular (see Figure 11). Louvers can vary in width and length and may .

It is recommended that the ratio of the open hem radius to the sheet metal thickness should be greater than or equal 0.5. Also, the ratio of return flange height to the sheet metal thickness should be greater than or equal to 4. Where, H = Return flange height D = Open hem diameter T = Sheet metal thickness

thinning in sheet metal forming

sheet metal lance stamping

BIOGRAPHY. After brother Lance graduated from Bates Technical College he started his apprenticeship with SMART Local 66 in 1988. Lance turned out as a Building Trades Journeyman in 1992 and worked at Olympia Sheet Metal, US Sheet Metal and Sunset Air as a Journeyman, Foreman and Superintendent.

PUNCHING AND FORMING SHEET METAL IN A PUNCH PRESS ENVIRONMENT G GS. Dimensions in Inches (mm) . Lance and Form 60-61 Bridge Lance and Form 62 Double Bridge Lance and Form 63 Closed End Louver 64-65 Parts Marking: Easymark 66-67 Parts Marking: Sheetmarker 68 Parts Bending: Easybend 69

Metal Supermarkets shears all types of metal in sheet and plate to your exact specifications. Order as few or as. Learn more Waterjet Cutting . We are located on the corner of Lance Rd and Lowery Rd – just off of North Military Highway near the Janaf Shopping Center, and with easy access to I-64 and I-264. .

Narito Sheetmetal & Mechanical Corporation in Waipahu, HI | Photos | Reviews | 11 building permits for ,886,500. Recent work: (bp #910557) [tmk: 89007009] [doe job no. p83225-22] 89-778 haleakala avenue nanakuli elementary school - alterations to existing air conditioning [third party review]. Sheet Metal Contractor, Ventilating And Air Conditioning .

Experience: Brox Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part . Experience: HVAC/Sheet Metal Drafting Lance and form tools cut the material in the punch press and form it for use in fastening applications. Thread forms provide a fast, cost-effective way to hold sheet metal finishing screws in place. In particular, they help eliminate secondary operations where a threaded hole is needed in thin material.

Minimum Distance from Bend to Lance During lancing operation a sufficient degree of clearance should be given around the lance feature and bend. It is recommended that minimum distance between lance and bend should be 3X the material thickness plus bend radius. t = Sheet metal thickness r = Inside bend radius r d Seven instructors worked hard to organize lesson plans — as many as 142 in a two-week period — and filter the apprentices’ questions, said Lance Clark, administrator for SoCal Sheet Metal Joint Apprenticeship and training Committee (JATC), Local 105 near Los Angeles.

Canonical method to implement lance features in NX sheet metal module. I'm trying to follow this tutorial, but can't find a proper way to implement the lanced features: on top right of the above drawing. Except this question/discussion from 2006, I could not find any other relevant information on internet in this regard. I would appreciate if . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Get more information for Lanz Sheet Metal & Heating & Fireplaces in Monroe, WI. See reviews, map, get the address, and find directions. Advertisement. Advertisement. Search MapQuest. Hotels Food Shopping Coffee Grocery Gas. Lanz Sheet Metal & Heating & Fireplaces +1 (608) 325-2581. site. More. Directions. Advertisement.

In low carbon steel sheet metal, the minimum radius of a bend should be one- half the material thickness or 0.80 mm (0.03 inch), whichever is larger. . The minimum width of an open lance is two times the material thickness or 3.00 mm (0.125 inch), whichever is greater, with a maximum length of five times the width. .A louver in sheet metal design is typically a formed feature made with a punch press incorporating a top and bottom die. When formed the metal is slit across the length of the louver and forced up into the die. The sides of the feature will not be slit. This forms a raised window in the part which is protected on three sides and open on the fourth. Experience: SHEET METAL WORKERS .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Experience: Tinker AFB 76 CMXG

press forming of sheet metal

lancing process in sheet metal

Perfect for installations that require a waterproof connection for multiple electrical cables, it's the best waterproof junction box for areas such as lockers, lazarettes, and tender bays. This Scanstrut junction box boasts marine-grade polypropylene and has 5 screw-down terminals.IP68 Waterproof: The Helunsi 3 way junction box is of IP68 high-level waterproof class, weatherproof, moisture-proof, dust-proof and anti-UV, making it safe to use in the sun, .

lance in sheet metal|how to joggle sheet metal