sheet metal quality standards This guide provides essential information on quality assurance for architectural sheet . Octagon (ceiling) box screws are 8-32. Wall box screws are 6-32. Fan support box screws and ground connection screws are 10-32. Both ceiling and wall box screws are typically about 1-1/4" long, combo head.The most common size screw to use in an electric box is a 6-32 flathead screw. For heavier applications, like ceiling lighting and ceiling fans, an 8-32 screw will work better. Ground screws in electrical boxes are always 10-32 .

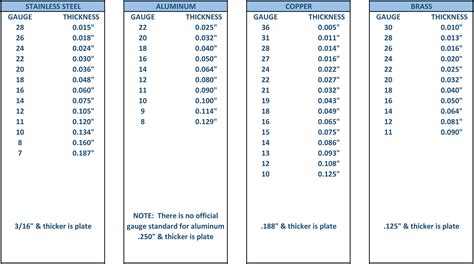

0 · standard thicknesses of sheet metal

1 · standard sheet sizes in mm

2 · standard sheet metal size chart

3 · sheet metal types and grades

4 · sheet metal specifications chart

5 · sheet metal guidelines pdf

6 · basics in sheet metal design

7 · 20 gauge sheet metal lowe's

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

SMACNA standards and manuals address all facets of the sheet metal and HVAC industry – including duct construction and installation, indoor air quality, energy recovery, roofing and architectural sheet metal, welding, and commissioning.This guide provides essential information on quality assurance for architectural sheet . For sheet metal fabrication, the prevalent standard is ISO 2768. This covers the tolerance requirements for multiple industries while maintaining the perfect balance between costs and processing capabilities. Understanding the manufacturing and quality standards for sheet metal folding machines is crucial for selecting and using these machines effectively. By considering factors such as materials, precision, bending capacity, tooling, safety, and maintenance, buyers can make informed decisions and optimize their sheet metal bending operations. .

Quality Standards is central to Universal Fabrications' business who are ISO9001 accredited and UKAS accredited for Coded Welding. Skip to content. 02476 370 272 . Universal Fabrications is a sheet metal fabrication and precision .

Richards Sheet Metal is proud to have recently upgraded their quality certification to the new ISO 9001:2015 standard. We use the requirements of this standard to assist us in achieving excellence in customer service, .

ASTM International has been the standards development partner of the metals producing industry for more than a century. Today, thousands of ASTM standards cover both ferrous and nonferrous metals, including steel, copper, aluminum and many others.

QM DCR # 18018 Date printed 24-Aug-22 Page 3 of 44 Quality Manual -01C ISO 9001-15 SECTION 1 Introduction 1.1 Introduction Fowler’s Sheet Metal, Inc. (FSM) developed and implemented a Quality Management System to document Voga subcontracts in many fabrication trades—bent tubing, precision sheet metal, spun metal, moldings, machined gizmos, glass, and granite, for example. If you’re interested in joining its supply chain, the company has a website. Voga is kindly allowing us to examine its visual inspection standard.

Whether you’re a seasoned engineer or a novice designer, this guide will help you create high-quality sheet metal parts that meet your project’s requirements and specifications. . Many manufacturers and industries prefer to set quality standards to avoid those inconsistencies. While these standards are not a one-size-fits-all solution . Sheet metal fabrication (bending, cutting, slitting, etc) is a whole other animal as it requires looser tolerances because of the higher variations. . Monitoring processes involved operator quality checks using standard check sheets and some statistical process control. The real breakthrough, however, was via solid quality engineering .

With a wide range of metal manufacturing processes, Tempco’s high quality certifications, licenses, and registrations guarantee that your parts are manufactured to the highest standards. Tempco has been a thriving sheet metal company for over 75 years, with turnkey sheet metal fabrication and metal stamping capabilities to meet our customers .

Enhanced Quality: Certifications play a crucial role in identifying quality sheet metal fabricators. ISO 9001:2015 and UL 1332 certifications demonstrate the sheet metal fabricator’s commitment to quality management systems and adherence to recognized industry standards. Choosing a certified fabricator ensures consistent product quality and .At Galaxy, sheet metal quality assurance is a top priority in our manufacturing process. We understand that sheet metal plays a critical role in various industries. That’s why we are dedicated to delivering sheet metal products that meet the highest standards of .Standards that define Quality and Performance At B & N Sheet Metal Inc., it is our belief that by offering the highest quality at a competitive price, we can build long lasting relationships. Products fabricated by B&N Sheet Metal are, B&N Sheet Metal Fabrication, Design, and Manufacturing in Wyoming, MN. B & N Sheet Metal is an established and modern, state-of-the-art sheet metal .

The scope of the Quality Management System includes the services required produce precision sheet metal parts and assemblies. The quality manual outlines the policies, procedures and requirements of the Quality Management System. The system is structured to comply with the conditions set forth in the International Standard ISO 9001-2008.F1267-18(2023) Standard Specification for Metal, Expanded, Steel . A1083/A1083M-23 Standard Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, Produced by Twin-Roll Casting ProcessAt Standard Sheet Metal Works, Inc. we are committed to creating the best possible products for your business and quality that you truly deserve. Thus, the job is not complete until we know that our customers are satisfied with the end .

The “SMACNA CAD Standard,” second edition, 2001, articulates in greater detail the CAD standards that will enable members of the AEC community to apply CAD effectively to mechanical, fire protection, and plumbing design and construction. . Architectural Sheet Metal Quality Assurance Guide. Architectural Sheet Metal Inspection Guide . Precision is paramount in aerospace sheet metal fabrication, as the intricate components must adhere to strict tolerances and quality standards to ensure the structural integrity and reliability of the final products. . The . In the world of manufacturing, metal material standards play a crucial role in ensuring consistency, performance, and quality across industries. Different countries and regions have developed their own systems for classifying and naming metals, such as ISO, ASTM, and JIS, each designed to meet specific industrial needs.Sheet metal fabrication is a precise and intricate process that demands a keen focus on quality to ensure that the final products meet the highest standards. Whether you are a manufacturer or a customer, quality is paramount to the success of any sheet metal fabrication project.

Sheet Metal Tolerances management and Quality Control . ISO Standards: The International Organization for Standardization provides a comprehensive standard set for sheet metal fabrication. ISO 2768, which sets benchmarks without specifying individual tolerances for dimensions, is widely used to define general tolerances. .Standard Sheet Metal is an industry leader in architectural, commercial, and industrial metal fabrication & manufacturing custom steel components. Standard Sheet Metal Toggle NavigationVerification of any non-conformance shall be conducted by Quality and/or Manufacturing . A deterioration of the metal resulting in change of color and leaving a rough surface that may show pits (small cavities). . coating standard for acceptance criteria). 6.3.7 Name Plates – Name plates should be visible and easily read, minor nicks that .Standard Sheet Metal Works, Inc. provides modern punching capability to provide holes and other special features that the customer demands with the highest quality! . Standard Sheet Metal Works, Inc. provides quality assembly services to help make those parts user ready upon delivery. WELDING. Highest Quality MIG Welders operated by Certified .

At Michaels Sheet Metal, our fabrication process is designed to turn blueprints into high-quality metal products with precision and efficiency. From the initial consultation to the final delivery, we are dedicated to maintaining the highest standards of quality and craftsmanship.Standard Sheet Metal Works, Inc. is recruiting! We’re looking for people who are passionate about helping others and making a great product. . The Quality Control Inspector is responsible for inspecting products to ensure they meet quality and contract specifications and meet external certification standards. Apply Now. entry level operator .

Our business in the metal industry began in 1958. We have been working arduously ever since to provide the best roofing and metal building products in Belize. Our standards of quality are one of the key factors of our business’ success. We remain committed to satisfying our customers through high-quality and the best value in metal.

Standardization & Quality Control of Iron & Steel. India is the 2nd largest steel producer in the world and also approaching towards a full quality regime. To achieve the objective of full quality regime, it is necessary to bring all the relevant Indian steel standards under the ambit of the steel quality control order.

metal house doors with windows

A touch of something galvanized or zinc adds a bit of a farmhouse industrial, unpretentious and homey feel to the normally shiny Christmas decorations and natural greenery. I love of a mix like that! Several metal .

sheet metal quality standards|20 gauge sheet metal lowe's