cnc gear making machine Nidec Machine Tool America offers a wide variety of CNC-controlled gear hobbing machines to meet the requirements of the high-volume producer as well as the small-lot job shop. Ranging in part sizes from 10mm to 1,000mm, you can find . 1. Carbide 3D Shapeoko 4: Best Wood CNC Carving Machine for DIYers; 2. BobsCNC Evo 4: Best CNC Wood Router for the Money; 3. Axiom Iconic Series: User-Friendly Wood Carving Machine; 4. BobsCNC KL744: Best Large CNC Machine for Woodworking; 5. ZMorph Fab: Most Versatile Wood CNC Machine

0 · internal gear cutting

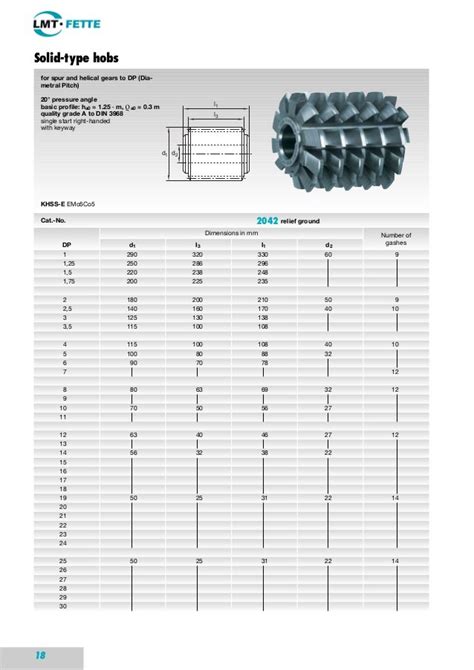

1 · hobbing cutter chart

2 · gear hob cutter catalogue

3 · gear cutting on milling machine

4 · gear cutting on a lathe

5 · gear cutters for milling machine

6 · cutting gears on a mill

7 · cnc bevel gear cutting machine

Describe the main parts of the EMCO CNC turning machine. Operate the EMCO CNC turning machine. Identify the main reference points on the EMCO CNC turning machine.

Nidec Machine Tool America offers a wide variety of CNC-controlled gear hobbing machines to meet the requirements of the high-volume producer as well as the small-lot job shop. Ranging in part sizes from 10mm to 1,000mm, you can find .

Each machine is CNC-controlled with servo control on precision linear roller ways, hand-scraped bearing surfaces, and accurate ball screws for easily achieving high tolerances. Our conversational HMI guides the operator through the gear .Nidec Machine Tool America offers a wide variety of CNC-controlled gear hobbing machines to meet the requirements of the high-volume producer as well as the small-lot job shop. Ranging in part sizes from 10mm to 1,000mm, you can find an NMTA machine that will cut your gear.Each machine is CNC-controlled with servo control on precision linear roller ways, hand-scraped bearing surfaces, and accurate ball screws for easily achieving high tolerances. Our conversational HMI guides the operator through the gear hobbing process, reducing specialized training required to run the machine.Whether compact or large, our gear hobbing machines impress with their flexibility. They can be used to machine workpieces from 20 millimeters up to oversized gears with a diameter of 16 meters.

The Hera 350 vertical CNC gear hobbing machine combines advanced technology, precision components, and economic pricing to enable profitable production of high-quality spur gears, helical gears, and other hobbed profiles.Task: Replace a traditional mechanical guide slide with a CNC to create an incredibly versatile and technically advanced gear-cutting machine. Solution: Use a FANUC model 31i B CNC to provide a highly precise and entirely electronic guidance system on the machine.

internal gear cutting

Today, each process uses an NC gear manufacturing machine, such as a hobbing machine (machine for cutting out teeth). These gear manufacturing machines allow operators to easily adjust the cutting speed and to specify the number of gear teeth.Find a large selection of new & used Gear Cutting Machines for sale at MachineSales.com. Buy machinery and equipment from leading dealers across America.Define your gear geometry by importing the gear data from your component drawing. Choose your machining strategy, add roughing and finishing operations and select tools to be used from the tool library. Simulate the machining process to verify tool paths before automatically generating a CNC program for your machine.

One such technological marvel is the use of Computer Numerical Control (CNC) machines in gear making. In this blog post, we will explore the ins and outs of CNC gear making machines, their features, benefits and how they have revolutionized the gear manufacturing industry.Explaining a simple way to machine spur gears from aluminum on a desktop cnc milling machine. Includes useful endmill buying advice.Nidec Machine Tool America offers a wide variety of CNC-controlled gear hobbing machines to meet the requirements of the high-volume producer as well as the small-lot job shop. Ranging in part sizes from 10mm to 1,000mm, you can find an NMTA machine that will cut your gear.Each machine is CNC-controlled with servo control on precision linear roller ways, hand-scraped bearing surfaces, and accurate ball screws for easily achieving high tolerances. Our conversational HMI guides the operator through the gear hobbing process, reducing specialized training required to run the machine.

Whether compact or large, our gear hobbing machines impress with their flexibility. They can be used to machine workpieces from 20 millimeters up to oversized gears with a diameter of 16 meters.

The Hera 350 vertical CNC gear hobbing machine combines advanced technology, precision components, and economic pricing to enable profitable production of high-quality spur gears, helical gears, and other hobbed profiles.Task: Replace a traditional mechanical guide slide with a CNC to create an incredibly versatile and technically advanced gear-cutting machine. Solution: Use a FANUC model 31i B CNC to provide a highly precise and entirely electronic guidance system on the machine.Today, each process uses an NC gear manufacturing machine, such as a hobbing machine (machine for cutting out teeth). These gear manufacturing machines allow operators to easily adjust the cutting speed and to specify the number of gear teeth.Find a large selection of new & used Gear Cutting Machines for sale at MachineSales.com. Buy machinery and equipment from leading dealers across America.

Define your gear geometry by importing the gear data from your component drawing. Choose your machining strategy, add roughing and finishing operations and select tools to be used from the tool library. Simulate the machining process to verify tool paths before automatically generating a CNC program for your machine.One such technological marvel is the use of Computer Numerical Control (CNC) machines in gear making. In this blog post, we will explore the ins and outs of CNC gear making machines, their features, benefits and how they have revolutionized the gear manufacturing industry.

hobbing cutter chart

Choose from our selection of steel brackets in a wide range of styles and sizes. In stock and ready to ship.

cnc gear making machine|gear hob cutter catalogue