solidworks for the sheet metal guy Maintain design intent of a hole pattern using a Fill Pattern. Learn how to use . When you're working with a high-speed machine or metal forming process, it's important to make sure you're using a lubricant that can offer a lot in the way of cooling properties. For most high-speed applications, water-based or soluble oil .No matter where you go, you will find these pesky chunks of metal we like to call locks. Whether you are trying to figure our which lock is the most secure or the easiest to pick, we cover all the intricacies of the various types of locks seen in the wild. We’ve put together this simple guide so you can pick all . See more

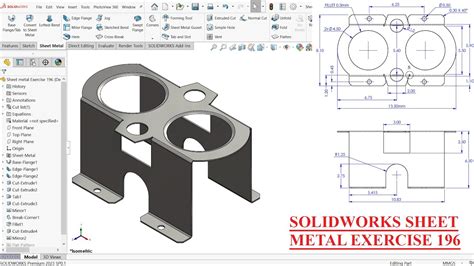

0 · solidworks sheet metal tutorial

1 · solidworks sheet metal pdf

2 · solidworks sheet metal exercises pdf

3 · solidworks sheet metal examples

4 · solidworks sheet metal download

5 · solidworks sheet metal basics

6 · sheet metal modeling in solidworks

7 · sheet metal drawing in solidworks

Known for its excellent corrosion resistance, high ductility, good strength-to-weight ratio, and impeccable shine after anodizing, aluminum has become a cornerstone in various industries. Let’s explore the different types of aluminum sheet metal alloys and what makes them so popular today. What Makes Aluminum Sheet Metal So Popular?

Learn how to use SolidWorks and its sheet metal tools from experts in the sheet metal industry. From the beginning, sheet metal parts are designed with manufacturing in .Maintain design intent of a hole pattern using a Fill Pattern. Learn how to use .Books. ›. Computers & Technology. ›. Programming. Other Used and New .Learn how to use SolidWorks and its sheet metal tools from experts in the sheet metal industry. From the beginning, sheet metal parts are designed with manufacturing in mind. Course 1 guides you step by step through the basics of .

Maintain design intent of a hole pattern using a Fill Pattern. Learn how to use and customize the SolidWorks Design Library, allowing you to create and use standard shapes and even your own forming tools and special .

Books. ›. Computers & Technology. ›. Programming. Other Used and New from 7.19. 137. Select delivery location. SolidWorks For The Sheet Metal Guy - Course 3: Unfolding Paperback – November 14, 2006. by Joe ."SolidWorks for the Sheet Metal Guy - Course 2: Hole Patterns and Notches shows numerous methods to create the commonly used holes, punching shapes, and patterns. Learn how to create line, grid, arc, and BHC patterns. Maintain .

This third book in the series explains the sheet metal unfolding process of getting the correct flat pattern layout. Providing step by step instruction in the use of the SolidWorks 2007 sheet metal features, this book shows you how to setup your .SOLIDWORKS has specific sheet metal features that allow the creation of sheet metal bodies very quickly. However, in some circumstances, when the design demands certain types of .

solidworks sheet metal tutorial

Manufacturing Software. Sheet Metal Guy LLC now offers its SolidWorks for the Sheet Metal Guy training book series in full color, making it easier to follow along. Sheet metal . SolidWorks For The Sheet Metal Guy - Course 3 by Joe Bucalo and Neil Bucalo, November 14, 2006, Sheet Metal Guy, LLC edition, Paperback in English - 2007 editionLearn how to use SolidWorks and its sheet metal tools from experts in the sheet metal industry. From the beginning, sheet metal parts are designed with manufacturing in mind. Course 1 .

SW/SE as general purpose CAD with Dedicated Sheet metal CAD/CAM like RADAN. All sheet metal fabricators we deal at work use that combo. Additionally - request demo from your CAD reseller. Ask them to duplicate some reasonably complicated model using sheet metal tools in SW/SE and check which one fits your requirements.

"SolidWorks for the Sheet Metal Guy - Course 1: Part Creation” demonstrates how to create real life sheet metal parts utilizing the basic command features provided in the SolidWorks Sheet Metal toolbar. Written in terms sheet metal people know and understand, this new book is a fun and engaging way to explore the sheet metal capabilities of .

When you mirror a sheet metal part, many of the bends are mirrored as well. Click Back (Heads-up View toolbar).; Zoom to the right corner of the model's back face. Click Mirror (Features tab).; Select one of the back planar faces, as shown, for Mirror Face/Plane.Parts that are originally created as sheet metal have different features than parts that are created, and then converted to sheet metal. However, you can add sheet metal-specific features to parts converted to sheet metal. As soon as you add a sheet metal-specific feature, (a Miter Flange, an Edge Flange, and so on), bends for new sheet metal .Best prices for Sheet Metal Guy, LLC book ISBN 0979566630 by Joe Bucalo and Neil in paperback. See FAQ about edition 2007 of SolidWorks For The Sheet Metal released November 14, 2006 and compare offers instantly! Help Content Version: SOLIDWORKS Connected Tutorials (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.

the dude with cad for engineers (youtube). i think he's got videos specific to advanced sheet metal. he speaks clearly and explains what he's doing; even explains when he messes up. I'd check it out though. and of course, goengineer.Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .SolidWorks for the Sheet Metal Guy is written by Neil Bucalo and Joe Bucalo. Neil is a CAD expert, having over 14 years of experience using numerous CAD systems. He has a diverse background, including mechanical engineering, CAD/CAM consulting, support, training, and technical writing. Neil is a Certified SolidWorks Support Technician.Start a new part > create a base flange > set the sheet metal parameters to whatever you want > delete the base flange feature and any sketches > save as part template > enjoy your new defaults Extra tip: K factor is a dimension that can be used in custom properties. The syntax is "D2@[email protected]". I have my templates set so .

"SolidWorks for the Sheet Metal Guy - Course 1: Part Creation” demonstrates how to create real life sheet metal parts utilizing the basic command features provided in the SolidWorks Sheet Metal toolbar. Written in terms sheet metal people know and understand, this new book is a fun and engaging way to explore the sheet metal capabilities of .Radius and bend deduction numbers can be entered into the sheet metal feature in Solidworks so your flat patterns actually work out. . I delt with a guy to bend up a tight tray recently and the guy in the shop and I figured out a way to bend it with bend relief and made it work. Easier to just talk to the guy on the floor than fuck around in . Help Content Version: SOLIDWORKS Connected (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.When you mirror a sheet metal part, many of the bends are mirrored as well. Click Back (Heads-up View toolbar).; Zoom to the right corner of the model's back face. Click Mirror (Features tab).; Select one of the back planar faces, as shown, for Mirror Face/Plane.

SolidWorks for the Sheet Metal Guy is written by Neil Bucalo and Joe Bucalo. Neil is a CAD expert, having over 14 years of experience using numerous CAD systems. He has a diverse background, including mechanical engineering, CAD/CAM consulting, support, training, and technical writing. Neil is a Certified SolidWorks Support Technician.

SolidWorks For The Sheet Metal Guy - Course 3 by Joe Bucalo and Neil Bucalo, November 14, 2006, Sheet Metal Guy, LLC edition, Paperback in English - 2007 edition

For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Sheet Metal and Weldment Bodies. This part contains a mixture of ."SolidWorks for the Sheet Metal Guy - Course 3: Unfolding” shows you how to set up and use the bend tables in SolidWorks as well as the material types and gauge tables (sheet metal thickness). Instruction on creating a k-factor table (this is not documented by SolidWorks) is also included. Learn how to override the default bend value and bend .Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .

For Sheet Metal users, the new features in SOLIDWORKS 2025 are sure to excite. In addition to never-before-seen bend notches, the list of enhancements to existing features is long, so let's dive in. Read Article . SOLIDWORKS 2025 Sheet Metal - What's New SOLIDWORKS 2025 Sheet Metal - What's New. By Angelle Erickson. Monday at 08:06 PM . Help Content Version: SOLIDWORKS Connected (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.

Drawings of sheet metal parts can also contain views of the bent sheet metal part. Creating Sheet Metal Flat Pattern Configurations. You can create a configuration in a sheet metal part that shows the flattened part. Sheet Metal Gauge/Bend Table. Sheet metal gauge/bend tables store properties for a designated material.A multibody sheet metal part has multiple sets of specific sheet metal features in the same feature tree. There are also multiple flat pattern features. The cut list shows each individual body. Learn the process for creating a multibody sheet metal part, and also some of the uses of such a part. Use sheet metal tools to create a new sheet metal body. Use a linear or circular pattern, mirror .Perhaps you could use SolidWorks sheet metal to make flatable design for paper furniture . The guy took a part that he 3D modeled in solidworks and is now projecting views of it (front/top/bottom/etc). . I would model it, offset the surface 0.001", and then convert to sheet metal with 0.001" thickness, and bend radius, and very small gaps .SolidWorks for the Sheet Metal Guy is written by Neil Bucalo and Joe Bucalo. Neil is a CAD expert, having over 14 years of experience using numerous CAD systems. He has a diverse background, including mechanical engineering, CAD/CAM consulting, support, training, and technical writing. Neil is a Certified SolidWorks Support Technician.

SolidWorks for the Sheet Metal Guy: Buku Pelatihan Sheet Metal SEO Cantik 01.24. SEO Cantik. cemilan sehat bisa menjadi pilihan anda saat sedang menjalani diet, bukan berarti disaat kita diet,kita tidak makan tetapi harus lebih menajaga pola makan dan memilih makan"n yang rendah lemak, seperti Pancake Buah, Brownies Almond, Sereal, Oatmeal dan .Amazon.in - Buy SolidWorks For The Sheet Metal Guy - Course 1: Part Creation book online at best prices in India on Amazon.in. Read SolidWorks For The Sheet Metal Guy - Course 1: Part Creation book reviews & author details and more at Amazon.in. Free delivery on qualified orders.

how to operate electric box

how to paint stainless steel tool box

During the early 20th century, metal became a popular material for tool storage. This type of toolbox could be mass-produced, so it's easy to find vintage metal tool boxes in a number of styles. The simplest examples featured a metal box with a hinged lid and a clasp to hold the lid closed.

solidworks for the sheet metal guy|solidworks sheet metal pdf