sheet metal bending force calculator Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, . pm17:00) Address:No.688, Youming Road, Wujiang District, Suzhou City

0 · sheet metal blank size calculator

1 · sheet metal bending force formula

2 · sheet metal bending calculator free

3 · sheet metal bending angle chart

4 · sheet metal bend deduction chart

5 · shear and moment diagram calculator

6 · how to calculate bend deduction sheet metal

7 · bend allowance calculator for sheet metal

This is the junction box most people use on 11-speed Di2 bikes. Installing it isn't as straightforward as installing the older below-the-stem junctions, but it's not hard - you just need to know what you're doing.

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters .The V & U-shaped Bend Force Calculator is an essential tool in the realm of sheet .Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, .

house with alamo white metal roof

To effectively use a Bending Force Calculator, follow these steps: Select the Material: Choose the appropriate material from the provided list or input custom material properties. Enter Sheet .Wipe Bending Force Calculator. Sheet thickness (in): Die edge radius (in): Punch edge radius (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety: Bending force (lb):

The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel, and Weldox® or Strenx® high-strength steels. Now that you know the tonnage and . Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [ (0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend . The calculator takes into account various factors such as material thickness, tensile strength, bend width, and die opening to provide an accurate estimation of the bending force. This helps in optimizing the bending process, .

Sheet Metal; Bend Allowance; Bending Springback; V-Bending Force; Wipe Bending Force; Deep Drawing Force; Bend Allowance Calculator. Sheet thickness (in): . Wipe Bending Force Calculator. Sheet thickness (in): Die .Calculate the required force to bend a piece of sheet metal using V-bending, a process in which a V-shaped punch presses the sheet into a V-die. The bending force can be calculated from the sheet thickness, die opening, bend length, .

Bending Force Requirement Punch Workpiece T Die W Force T = Sheet Thickness W = Width of Die Opening L = Total length of bend (into the page) UTS = Ultimate Tensile Strength of material () 2 UTS W LT F= Note: the notation used in the text (L, W) differs from that used in the previous development (b, L).Wipe Bending Force Calculator. Calculate the required force to bend a piece of sheet metal using wipe bending, also called edge bending. In this process, the sheet is held between a wipe die and pressure pad, while a punch presses against the edge of the sheet. The bending force can be calculated from the sheet thickness, bend length, die edge .Sheet Metal Bending Parameters Calculator Here you can insert the characteristics of the sheet metal to be bent (internal radius, V-die opening and minimum flange) . The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel. Bending Force Calculation Our press brake bending calculator can help you based on the [.]Bending Force - (Measured in Newton) - Bending Force is the force required to bend a particular material about an axis. Bending Die Constant - Bending Die Constant is a numerical value used in metal working to quantify the relationship between applied force and material deformation during bending operations. Bent Part Length - (Measured in Meter) - Bent Part Length is the portion .

Use the TRUMPF BendGuide to calculate key bending parameters quickly and simply: Press force calculation; Press force table; Nesting height; Flange length; Die width; Open-height check; Inner radius; Sheet thickness conversion; Tool weight calculation; Sheet metal weight calculation; Download the app In the "More" menu item, you can convert the .Bending Force Calculator Get Free Quote. Relationship between V opening and plate thickness (1)S < 10mm, V opening = 8×S (2)10mm ≤ S <25mm, V opening = 10 × S (3)S >25mm, V opening = 12×S. . Not sure which machine is right for your sheet metal product? Let our knowledgeable sales team guide you in selecting the most suitable .

The V & U-shaped Bend Force Calculator is an essential tool in the realm of sheet metal fabrication, specifically tailored for calculating the force required to perform V-bending and U-bending operations.

The variables in this formula include: S: Sheet thickness; r: Inner radius during bending; K: Width of the horizontal projection of the bending deformation zone; From the derivation process, it is essential to meet two additional conditions when using formulas (2) or (3) to calculate bending force: the width-to-thickness ratio (V/S) must equal 9, and the radius-to-width ratio must equal .Bending force calculator CALCULATE THE REQUIRED BENDING FORCE WITH ALIKO CALCULATOR READ MORE . Please check sheet metal material and tensile strength from the list below! Materials: Rm - tensile strength (N/mm2) Mild steel S235: 510: Mild steel S355: 630: Raex 300: 1000: Raex 400: 1250:Bending rule and rulers to calculate the tonnage of "U" profiles, "Z" profiles, flattened profiles and offset Z profiles. . SHEET METAL UNFOLDING; Media; Catalogues; BLOG; About Us. About us; CORPORATE GOVERNANCE; Sustainability; . FORCE CALCULATION . menu. CALCULATORS Rolleri USA. 33720 Lear Industrial Pkwy, Avon, OH 44011 .

Wipe Bending Calculator. Calculate the required force to bend a piece of sheet metal using the wipe bending method. In this process, the sheet is held between a wipe die and clamp pad, while a punch presses against the edge of the sheet. The calculated tonnage can be used for the selection of a machine, such as a press brake, to perform the . Manufacturing: Sheet metal fabrication processes like cutting, punching, and blanking require precise calculation of shearing force to ensure efficiency and quality. 3. Structural Engineering: Shearing force analysis is .How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.

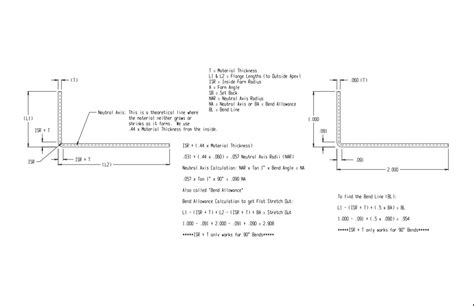

Sheet Metal Bending Equation and Calculator. Manufacturing Knowledge Menu Sheet Metal Knowledge. The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. .How to calculate the cutting force of a guillotine shear. With this calculator you can determine the force required to shear sheet metal, simply by entering the material’s ultimate tensile strength, thickness, and blade angle (rake angle). Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

Sheet metal bending calculator. Our online calculator allows you to determine sheet metal bending parameters within seconds accurately. Enter your project data and instantly get tonnage, inner radius and minimum edge. Die opening. The die opening is usually chosen according to the thickness of the sheet metal, with this rule: Thickness < 6 mm

Wipe Bending Force; Deep Drawing Force; Bending Springback Calculator. After a bending operation, residual stresses will cause the sheet metal to spring back slightly. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to acheive the desired bend radius and bend angle. The final bend radius and bend angle can . To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves creating a controlled deformation to form a .

Bending force calculator admin 2020-10-29T07:13:00+00:00. BENDING FORCE CALCULATOR. . Please check sheet metal material and tensile strength from the list below: Materials: Rm - tensile strength (N/mm2) Miilux 400: 1250: Miilux 450: 1400: Miilux 500: 1650: Protection 400:How long does it take to bend a sheet metal box. According to data collected by one of our customers, it takes several minutes to bend a sheet metal box of considerable size.The process has an important manual component, generates faulty parts, can cause damage and injury, and takes a long time. A box with rounded edges requires two operators and almost 2 minutes to .Calculate K factor and bend allowance for sheet metal bending; Calculate length and weight of a sheet metal coil; Calculate radiused bump bending; Online calculator for bending sheet metal boxes; Saving in tool changing; Shearing force calculator; Sheet metal bending parameters calculator; Sheet metal weight calculatorFlat Plate Deflection Calculator Simply Supported | Flat Plate Stress Calculator The plate deflects. The middle surface (halfway between top and bottom surfaces) remains unstressed; at other points there are biaxial stresses in the plane of the plate. . Bending stress at center (N/mm 2) = psi Reaction load at center of long side (N/mm) = lbs .

sheet metal blank size calculator

$20.99

sheet metal bending force calculator|sheet metal blank size calculator