electric vehicle battery box The EV battery boxes’ tray is made from soft steel, drawn to form completely vertical (90°) side walls that optimize the space for the battery pack. The tray also prevents the EV battery cells from leaking into the environment during and . Standard boxes are available in both metal and plastic. Plastic is lighter and is resistant to corrosion. Metal is more durable and can serve as a grounding conductor. Can be .

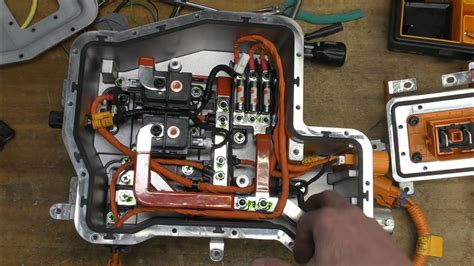

0 · ev battery junction box

1 · ev battery boxes

2 · electric car battery storage containers

3 · electric car battery box

4 · electric battery junction box

5 · battle for the ev battery box

6 · battery storage for electric cars

7 · aluminum ev battery box

Commonly there are two types of metal sheet screws available in the market. While standard units feature a pointed tip, which is ideal for cutting into the metal surface, the thread-cutting or self tapping screws feature a notched .

DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural .A battery enclosure that features a single-piece, metal-reinforced composite tray .

As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities.We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement .The EV battery boxes’ tray is made from soft steel, drawn to form completely vertical (90°) side walls that optimize the space for the battery pack. The tray also prevents the EV battery cells from leaking into the environment during and .

EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.Developed with the aim of expanding the pallet of aluminum solutions available for global high volume EV production, the Second-Generation of advanced aluminum sheet intensive design . A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application.

Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full . Electric vehicle (EV) battery trays are highly-engineered components that barely existed a few years ago but play a wide role in an EV’s safety, rigidity and weight – and therefore efficiency. They also need to be . DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural components. Its housing is made of the company’s Zytel HTN, a nylon-based polyamide capable of resisting high temperatures.

Aluminum extrusions produce high performance electric vehicle battery systems and packaging. Learn why aluminum extrusions are effective for robust battery box or housing design.

ev battery junction box

As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities.We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement system that .The EV battery boxes’ tray is made from soft steel, drawn to form completely vertical (90°) side walls that optimize the space for the battery pack. The tray also prevents the EV battery cells from leaking into the environment during and after a crash. EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.

Developed with the aim of expanding the pallet of aluminum solutions available for global high volume EV production, the Second-Generation of advanced aluminum sheet intensive design maximizes weight reduction, reduces costs, and delivers higher pack energy density compared to traditional EV battery enclosures made from steel or aluminum . A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application.

Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full-assembly capabilities. CSP continues to innovate its battery enclosure design, as well as its range of capabilities for customers.

Electric vehicle (EV) battery trays are highly-engineered components that barely existed a few years ago but play a wide role in an EV’s safety, rigidity and weight – and therefore efficiency. They also need to be watertight. DuPont’s 3-in-1 battery-box concept unveiled in late 2022 is a new example of modular design that consolidates cell cooling, electrical interconnection, and structural components. Its housing is made of the company’s Zytel HTN, a nylon-based polyamide capable of resisting high temperatures.Aluminum extrusions produce high performance electric vehicle battery systems and packaging. Learn why aluminum extrusions are effective for robust battery box or housing design. As electric vehicles become more popular, the challenge for automakers is to reflect true range while making vehicles more affordable. This means making the battery packs lower cost with higher energy densities.

We created our electric car battery storage cases to scale to fit future battery shapes and sizes, ensuring that customers save money by not replacing their cases with each new model. Our containers feature a universal securement system that .The EV battery boxes’ tray is made from soft steel, drawn to form completely vertical (90°) side walls that optimize the space for the battery pack. The tray also prevents the EV battery cells from leaking into the environment during and after a crash. EV battery box designs are structures that enclose the battery. They protect the vehicle’s powerhouse from external interference, such as in a car crash. Some may act as insulators or contribute to the battery’s cooling system.Developed with the aim of expanding the pallet of aluminum solutions available for global high volume EV production, the Second-Generation of advanced aluminum sheet intensive design maximizes weight reduction, reduces costs, and delivers higher pack energy density compared to traditional EV battery enclosures made from steel or aluminum .

A battery enclosure that features a single-piece, metal-reinforced composite tray and one-piece composite cover is a step closer to an electric vehicle (EV) production application. Overall, CSP reports that its multi-material battery enclosure is about 15% lighter than a steel battery box, with better temperature resistance compared to aluminum. Next-level innovations: Clips, impact shields, full-assembly capabilities. CSP continues to innovate its battery enclosure design, as well as its range of capabilities for customers.

ev battery boxes

This hammer is almost similar to a cross pane hammer, but its pan is straight to the hammer handle. It is also used as a cross pane hammer for making channels, “V” grooves, .

electric vehicle battery box|electric car battery box