cnc lathe machine lab report pdf ME- 319 F MANUFACTURING TECHNOLOGY –II LAB. Study and Practice of Orthogonal & Oblique Cutting on a Lathe. 2. Machining time calculation and comparison with actual machining time while cylindrical turning on a Lathe and finding out cutting efficiency. 3. Study of Tool Life while Milling a component on the Milling Machine. 4.

Zintec sheet refers to a steel plate that has been coated with a thin zinc layer. Along with its great machinability, this makes it suitable for the manufacture of car bodies, signs, air conditioning units and even washing machines.

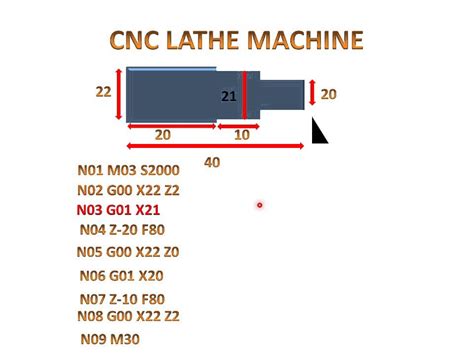

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

Heat retention - 162 degrees Fahrenheit at 6 hours. Made of BPA-free plastic and stainless steel. The Tiffin Box comes with a vacuum insulated outer container that houses three bowls, ideal for holding curries or other foods hot or cold, and one side bowl at room temperature. Includes a .

cnc turning program examples PDF

Download Lab Report CNC Lathe. Objective: To learn how to fully use a CNC Turning machine, from understanding how to design the work piece to learning how to safely .ME- 319 F MANUFACTURING TECHNOLOGY –II LAB. Study and Practice of Orthogonal & Oblique Cutting on a Lathe. 2. Machining time calculation and comparison with actual .Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and tooling .

CO2: Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and .

cnc turning machine programming PDF

cnc turning cycle program PDF

Download Lab Report CNC Lathe. Objective: To learn how to fully use a CNC Turning machine, from understanding how to design the work piece to learning how to safely operate the machinery and its many functions, such as drilling, roughing, facing and threading.ME- 319 F MANUFACTURING TECHNOLOGY –II LAB. Study and Practice of Orthogonal & Oblique Cutting on a Lathe. 2. Machining time calculation and comparison with actual machining time while cylindrical turning on a Lathe and finding out cutting efficiency. 3. Study of Tool Life while Milling a component on the Milling Machine. 4.Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and tooling for various machining operations.

CO2: Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and tooling for various machining operations.

Lathe removes undesired material from a rotating work piece in the form of chips with the help of a tool which is traversed across the work and can be fed deep in work. The tool material should be harder than the work piece and the later help securely and rigidly on the machine. The tool may be given linear motion in any direction.Main parts of the milling machines are similar; all these machine essentials consist of the following main parts: 1. BASE: It is a heavy casting provided at the bottom of the machine. It is accurately machined on both the top and bottom surfaces. It actually acts as a load bearingA lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

1 Computer Numerical Control (CNC) Lathe Machine | Lab Report 1 Introduction Computer Numerical Control (CNC) machines have become very important in the manufacturing industries for machining repeatable and complex geometry parts.Lathe Machine Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides an introduction to lathe machines. It discusses the history and evolution of lathe machines from ancient Egypt to modern .

herters metal fly box

The document discusses CNC milling objectives, introduction, apparatus, safety procedures, and experimental procedures. The objectives are to understand CNC development and NC code fundamentals, and to produce a product using CNC machinery.

Download Lab Report CNC Lathe. Objective: To learn how to fully use a CNC Turning machine, from understanding how to design the work piece to learning how to safely operate the machinery and its many functions, such as drilling, roughing, facing and threading.ME- 319 F MANUFACTURING TECHNOLOGY –II LAB. Study and Practice of Orthogonal & Oblique Cutting on a Lathe. 2. Machining time calculation and comparison with actual machining time while cylindrical turning on a Lathe and finding out cutting efficiency. 3. Study of Tool Life while Milling a component on the Milling Machine. 4.Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and tooling for various machining operations.CO2: Understand integral parts of lathe, shaping and milling machines and various accessories and attachments used. Select cutting parameters like cutting speed, feed, depth of cut, and tooling for various machining operations.

Lathe removes undesired material from a rotating work piece in the form of chips with the help of a tool which is traversed across the work and can be fed deep in work. The tool material should be harder than the work piece and the later help securely and rigidly on the machine. The tool may be given linear motion in any direction.Main parts of the milling machines are similar; all these machine essentials consist of the following main parts: 1. BASE: It is a heavy casting provided at the bottom of the machine. It is accurately machined on both the top and bottom surfaces. It actually acts as a load bearing

A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. 1 Computer Numerical Control (CNC) Lathe Machine | Lab Report 1 Introduction Computer Numerical Control (CNC) machines have become very important in the manufacturing industries for machining repeatable and complex geometry parts.Lathe Machine Lab Report - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document provides an introduction to lathe machines. It discusses the history and evolution of lathe machines from ancient Egypt to modern .

cnc programming for dummies PDF

Enjoy the durability of this metal box spring made from a heavy gauge steel that does not require any assembly. In the wondrous world of Zinus, mattresses are marshmallows and bed frames snap together in seconds.

cnc lathe machine lab report pdf|cnc programming for dummies PDF