how to calculate bend radius of sheet metal There are lots of different paths to find your way around a bend, by using either the included or complementary angles. We can easily calculate these values; it is the applicationof the . See more Zinc, Copper, Aluminum, Or Steel: For those looking to cast a key at home, these metals are the best materials for casting. They provide a sturdy and reliable duplicate, although they might not be as durable as professionally .

0 · sheet metal bending calculator free

1 · sheet metal bending angle chart

2 · sheet metal bend radius formula

3 · sheet metal bend length calculator

4 · sheet metal bend calculation formula

5 · calculating bend allowance sheet metal

6 · bending force calculator sheet metal

7 · bend radius calculator in inches

A junction box makes that easier by allowing you to connect directly to the main breaker. This negates the need to running wire through the entire house back to the breaker, providing that the power requirements of those components .

sheet metal bending calculator free

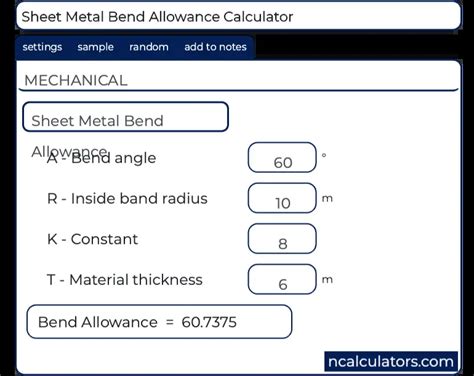

Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary The length of the neutral axis is calculated as a bend allowance, taken at 50 percent of the material thickness. In Machinery’s Handbook,the K-factor for mild cold-rolled steel . See moreThere are two basic ways to lay out a flat blank, and which to use will depend on the information that you are given to work with. For the first method, . See moreThere are lots of different paths to find your way around a bend, by using either the included or complementary angles. We can easily calculate these values; it is the applicationof the . See more

A simple and rough method to determine the bending radius is: If the plate thickness is less than 6mm, the bending radius can be equal to the plate thickness. If the plate thickness is between 6mm and 12mm, the bending .

Input Material Thickness and Inner Radius: • Enter the precise sheet thickness and desired inner bend radius. • The calculator will instantly provide the K-factor, Y-factor, and neutral layer position, crucial for accurate .

Among them are the workpiece material and thickness, the bend angle and inside radius, the method used to bend the metal (air vs. bottom bending), and the oft-misunderstood K-factor, also known as either the neutral factor or the Y-factor. Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today! To calculate bend allowance: Obtain the properties of the bend (bend radius, angle, and method used). Obtain the characteristics of your material (thickness and K-factor for this specific bend). Input everything into the bend .

In this Tech Tip, we will explore the various bend calculation options available for sheet metal, namely K Factor, bend allowance, and bend deduction, and guide you on when to use each.

Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors . Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. .

This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange. You just have to insert the characteristics of the sheet metal to be bent. The tool can calculate .Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, minimizing errors . When the bending radius is large and the bending angle is small, the degree of deformation is low and the neutral layer is close to the center of the sheet thickness.. However, when the bending radius (R) becomes smaller and . How is the bend radius calculated for sheet metal? The bend radius for sheet metal can be calculated using a simple formula. It is typically expressed as a multiple of the material thickness. To calculate the bend radius, multiply .

How to calculate tonnage, internal radius and other bend parameters. This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange.You just have to insert the characteristics of the sheet metal to be bent. So in this case, a 0.472-in. die opening will give you a 0.0755-in. floated inside bend radius on the part. When your die opening changes, so does your inside radius. If the die opening is 0.551 in. (0.551 × 0.16), the inside bend radius changes to 0.088; if the die opening is 0.972 in. (0.972 × 0.16), the inside bend radius changes to 0.155.

sheet metal bending angle chart

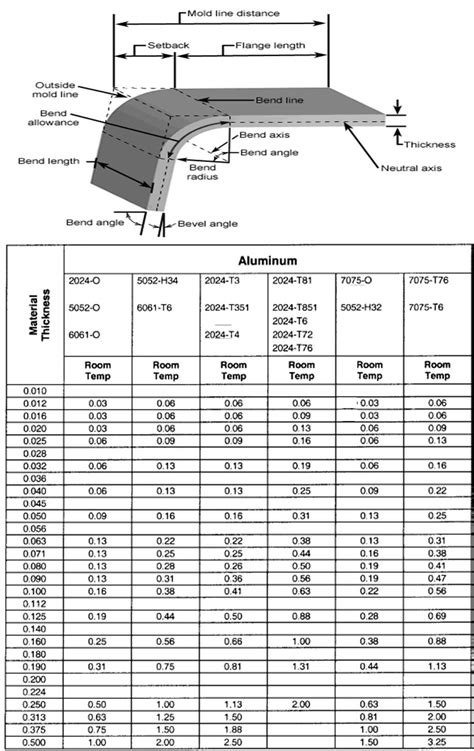

We are going to review three bending scenarios with three different bending angles; 60, 90 and 120, and we will calculate K-Factor, Bend Allowance and Bend Deduction for them. The bending tool has a radius of 30 mm which means that our Inside Bend Radius (R) is 30 mm. Let’s start with 90 degrees bend which is the most simple scenario. Q: In a previous Bending Basics article, you mention a “material’s tensile reduction percentage” used for calculating the minimum inside bend radius of various metals. You described a rough rule to find a steel’s minimum bend radius: Divide 50 by the material’s reduction percentage, as specified by the material supplier, subtract by 1, and then multiply by the plate . Once the material thickness and bend radius are known, the bend allowance can be calculated using empirical formulas. One common formula is the K-factor method, which considers the material type and the bend radius. The K-factor is a constant that varies with the material and bend radius. For example, for mild steel, the K-factor for a bend . Question: My co-workers and I have been reading your columns to help us understand what tooling our shop will need to avoid overstressing our materials with small dies. We air bend our 0.125-inch-thick 5052-H32 aluminum with a 1-mm punch and 16-mm die. Based on your columns, the inside bend radius should be 13 to 15 percent of the die opening.

How to calculate the value of material shrinkage. With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.

How To Calculate Bend Radius. Calculating the bend radius for different metals involves understanding the material properties and the specific parameters involved in the bending process.Bend radius is critical in metalworking, particularly in the fabrication of components such as sheet metal parts, where excessive bending can lead to material failure.Bending radius is often used in sheet metal working. This page explains the working methods, measurement problems, and how to measure 3D shapes accurately. . making it difficult to calculate the correct value using a mathematical formula. Therefore, it is necessary to set the minimum bending radius based on experience or testing, and . We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material. Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.)

In such cases, the steel plate bending radius and sheet metal bending force calculation also become paramount. . Understanding how to calculate bend allowance is like cooking a gourmet meal; you need to know how each . To understand why the K-factor cannot exceed 0.5, it’s crucial to comprehend the concepts of the K-factor and the neutral layer in sheet metal bending. Understanding Sheet Metal Bending. Sheet metal bending involves .

For a sheet metal stock with inch thickness, determine the minimum tool radius for both the steel and aluminum alloys that will not tear the material. Assume the sheet of material is in pure bending (i.e., no additional tension is .Quick calculation of the angle of a radius bend However, many consecutive bends can cause an accumulation of errors, both in terms of the final angle and the radius of the bend. For this reason, it is important to rely on a press brake with a very precise backgauge and . To enhance the readers’ understanding of basic concepts in sheet metal design calculation, the following points will be summarized and explained:. The definitions of the two bending algorithms: bend allowance and bend deduction, and their connection to the actual sheet metal .

K-factor in sheet metal is a constant used to calculate sheet metal bend allowance, bend deduction, Flat length and Neutral axis position. . Mathematically outside setback is equal to the product of the sum of sheet thickness & inside bend radius and tangent of the half of bending angle. Outside Setback ( OSSB ) = Tan (A / 2) × (T + R)

Factors Influencing the Minimum Bend Radius. The minimum bend radius of the sheet metal is affected by several factors, each of which is of specific importance in determining the most desirable degree of bend that would prevent collapse or paper deformation. tAng factors include:. Material Type: Different materials have varying levels of ductility and tensile strength, .

Many designers reference a chart like this or use test pieces to calculate the K-Factor for specific projects. . For the Bend Calculation option, the spreadsheet applies one of three equations – depending on the angle of the bend – to the sheet metal design. With the Bend Table option, each of the available tables extracts the values for .Bend allowance is a fundamental parameter to calculate sheet elongation. . Sheet Metal Bending: . (actually 80-100° I don't use it) or where I'm folding with non standard V Tooling, like a radius tool. I use a bend deduction for most things - but the parts I . (2) Bending radius calculation formula. Sheet metal bending parts require a bending radius r at the bend. Typically, the blueprints for sheet metal parts have clear markings for the bending radius. The final size after bending is determined by the punch radius r 0 and the amount of springback r, i.e., r = r 0 + r.The bend allowance and bend deduction are two measures that relate the bent length of a piece of sheet metal to the flat length. The bend allowance describes the length of the neutral axis between the bend lines, or in other words, the arc length of the bend. Therefore, the bend allowance added to the flange lengths is equal to the total flat .

The k-factor is fundamental in the press-bending sector and is closely linked to the concept of spring back. It is also known as bend allowance and serves to calculate the sheet metal layout. Knowing the k-factor formula is essential in order to bend any kind of sheet metal correctly; in fact, it varies according to the type of material to be deformed. . Bend Radius Defined. The bend radius is the radius of the arc created after bending the sheet metal. It can be measured from either the inside or the outside of the bend. If the radius is too small, the metal could crack, break, or deform, ruining the product. The smaller the bend radius, the more severe the curve of the bend. Metals with small .

For cutting sheet metal, the first step is to make sure you have the right tools for the job. A sharp pair of shears are best for thinner metals, but for thicker metals, a saw such as a reciprocating saw or jigsaw is ideal.

how to calculate bend radius of sheet metal|sheet metal bending calculator free