history of sheet metal forming process Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by . When selecting tools, consider the type of work you will be doing, your budget, and reviews and recommendations from other metal fabricators. With the right tools and equipment, you can tackle any metal fabrication project with confidence and produce outstanding results.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal operations with diagrams

4 · sheet metal forming process pdf

5 · sheet metal bending process pdf

6 · forming sheet metal by hand

7 · bulk deformation vs sheet metal forming

Below, we explore the top options to help gain high-quality results in any fabrication process. 1. CNC Machines. CNC (Computer Numerical Control) machines use computer technology to control machine tools, producing more precise cuts. Their components are quite complicated, including the following:

This article is focused on tracing a synthetic history of sheet metal and its machining. We must first of all distinguish three fundamental aspects, .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by .Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . Almost two centuries after the first rolling mill was developed, the process for creating sheet metal was perfected by Jean Pierre Droz in 1770. Droz was a coin and metal engraver who worked to improve the quality of coinage .

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .Although sheet metal was worked for thousands of years in the production of coins. utensils and objects of art. it was only a century ago that the process was mechanized and began to .

The incremental sheet metal forming process, one of these novel techniques, has attracted a great deal of attention in recent decades. This paper presents a review of recent work done in this area and captures ideas for .This unique textbook features fundamentals and analyses of metal forming processes supported by 200 worked numerical examples. It provides rigorous detail on the three all-important groups of metal-forming processes: bulk-metal .

Although the advantages of formability are notable, blow-forming processes, which are classified as sheet metal stretching processes, present limits in terms of uniformity of the .Incremental sheet forming (ISF) featured with low cost, high customization and small quantity production [19] is achieved through the accumulation of the localized plastic deformation of the sheet, in which a hemispherical-head tool controlled by the computer program is used to form the metal [20].During the forming process, a designed 3D shape is dispersed into levels of 2D . 12. Sheet metal parts are usually made by forming material in a cold condition , although many sheet metal parts are in a hot condition because the material when heated has a lower resistance to the deformation. Spring or .

laws,aswellasforming limit curves as a specificity of the sheet metal forming processes. Consequently, the material modeling is strategic when models of reality have to be built. The book gives a synthetic presentation of the research performed in the field of sheet metal forming simulation during more than 20 years by the 1) Incremental sheet forming is an innovative metal forming process where a spherical tool is used to push a sheet into a desired shape without the need for dies. 2) The document provides an overview of the incremental sheet forming process, including its history and development, common methods like single-point and two-point forming . Although the advantages of formability are notable, blow-forming processes, which are classified as sheet metal stretching processes, present limits in terms of uniformity of the thicknesses of the produced product.

- space between the punch and the die Major factor in determining the shape and quality of the sheared edge As clearance increases the deformation zone becomes large and the sheared edge surface becomes rougher because the formability of the sheared part can be influence by the quality of its sheared edges, clearance control is important Dependent on: type of material and . This review will help researcher to be familiar about the history, development and state of art of metal forming processes of aluminum sheet alloys. The application of aluminum alloys in automotive and aerospace industries has been growing significantly in the last 20 years. Due to their high specific strength, aluminum became a strong .

This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and galvanized steel. It does have some limitations, however; the metal needs to have the same thickness throughout, and .

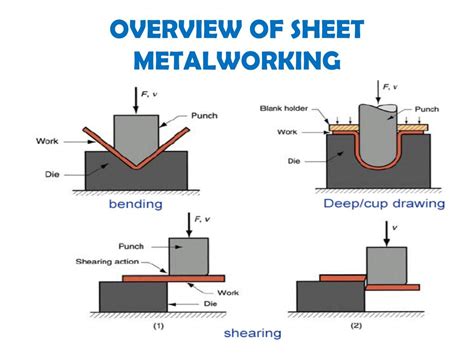

Deep drawing, a sheet metal forming process designed to produce hollow shells, was developed in the mid-19th century. Since that time, much has been published regarding deep drawing dies and processes, but very little can be found regarding its origin.Incremental sheet forming (or ISF, also known as Single Point Forming) is a sheet metal forming technique where a sheet is formed into the final workpiece by a series of small incremental deformations. However, studies have shown that it can be applied to polymer and composite sheets too. Generally, the sheet is formed by a round tipped tool, typically 5 to 20mm in diameter.is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. In bending process, the outside portion of the sheet is in.

sheet metal working process pdf

Search the history of over 866 billion web pages on the Internet. Search the Wayback Machine An illustration of a magnifying glass. . Vukota Sheet Metal Forming Processes And Die Design Industrial Press, Inc ( 2004) . BRASS, METAL, TOOL, ELECTRICAL DISCHARGE, MACHINISTS, MILLING MACHINES, .

The first objective is to demonstrate advances in sheet metal forming by specific examples with different degree of industrial readiness—from new process ideas to fully industrialized processes.Incremental sheet forming or ISF forming process is basically sheet metal working or sheet metal forming process. In this case, sheet is formed into final shape by a series of processes in which small incremental deformation can be done in each series. . Milestones in the History of Sheet Metal This page was last edited on 7 October 2024, at .After the precise cutting of metal sheets, the subsequent stage in sheet metal fabrication is the forming and shaping process. This phase is essential for giving the flat metal pieces their desired three-dimensional form.

Positive die-less incremental forming, also referred to as two-point incremental forming (TPIF), is another variant of ISMF and is known to be first attempted by Matsubara ().In this process (Fig. 4), clamped sheet can move .

Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodies Review of Incremental forming of sheet metal components, By Nimbalkar D.H and Nandedkar V.M, Int. Journal of Engineering Research and Applications, Vol. 3, Issue 5, Sep-Oct 2013, pp.39-51. Modeling of single point incremental forming process for metal and polymer sheet, By Le Van Sy, Ph.D Thesis , university of Pauda- 2009. Sheet Metal Today Sheet metal production is an integral part of modern economies. US Army Corps of Engineers / CC BY-SA. Sheet metal production continues to be an important industry in America and around the world. As of 2011, the sheet metal industry was worth .5 billion and over 4,400 sheet metal fabrication shops were in operation in the . In the indirect hot forming process, sheet metal is preformed through cold forming at first and then is put into the mold with the cooling system after it is heated to austenite temperature and held for a time it [2, 8]. The indirect hot forming process is also known as “multi-step” method of hot forming (Fig. 3.11). First the sheet is .

The method shown in Fig. 1 is iterative: for some set of process constraints, a target part is optimally “un-formed” to a flat blank; the deformation history of this un-forming is then reversed to calculate the strain and stress histories of the forwards forming process that would form the target part from the calculated flank blank. From these stresses, the boundary .Rolling schematic view Rolling visualization. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough.Rolling is classified according to the temperature of the metal rolled.

Study with Quizlet and memorize flashcards containing terms like Sheet Metal Forming, Almost all sheet metal forming processes are considered to be, What do sheet metal processes involve? and more. Scheduled maintenance: October 2, .

In the sheet metal hydroforming process, a metal blank is placed on the hydroform press. This blank is the metal sheet onto which pressure is applied, which forces the blank into the shape of the die beneath it. The advantage of this method is the versatility; a wide variety of parts can be formed using sheet hydroforming.Animation of a power press with a fixed barrier guard. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping .

sheet metal stamping process pdf

Types of Metal Forming Processes. Additionally, metal forming processes are classified into three types based on the type of workpiece: Bulk Forming Processes; Sheet Metal Forming Processes; Power metal forming process; Bulk Forming Processes. Bulk forming process involves using raw materials with a low surface area to volume ratio for shaping.

Deep drawing processes, which are often used in sheet metal manufacturing due to their high productivity, 3 lead to a geometry-dependent, locally different sheet thickness change and strain hardening of the materials. Subsequent joining processes, such as clinching, are distinctly influenced by the mechanical properties and thicknesses of the joining partners.

Electrical boxes are a fundamental component of any electrical system, playing a crucial role in safety and functionality. Understanding the different types and their applications can help you make informed decisions for your electrical projects.

history of sheet metal forming process|sheet metal working process pdf