first cnc milling machine The story of CNC machining dates back to the 1940s and 1950s, originating from the need for high-precision machining for the defense and aerospace industries during and after World War . Metal roofs are made of strong metals, including tin, aluminum, zinc, copper, and steel. They’re more durable than asphalt shingles, so they have longer life spans. Metal roofs can withstand extreme weather, such as heavy snow and radiant summer heat, and winds of .

0 · types of cnc milling machines

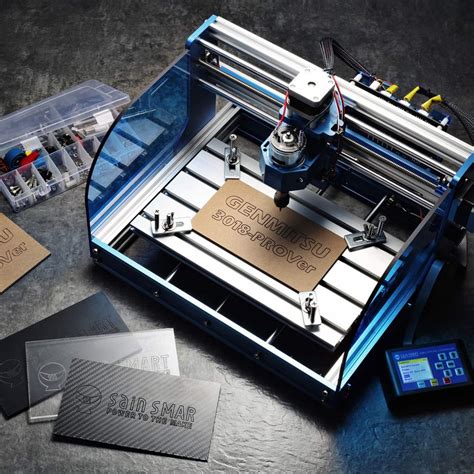

1 · most affordable cnc milling machines

2 · compact cnc milling machine

3 · cnc milling machine pdf

4 · cnc milling machine near me

5 · cnc milling machine description

6 · best milling machine for small shop

7 · affordable cnc milling machines

$4,705.00

The first CNC machine, a Cincinnati Hydrotel milling machine retrofitted with a computer control system, was introduced in the early 1960s. As computing technology advanced, CNC systems evolved from punch-card readers to more sophisticated computer interfaces. Parsons invented CNC machining around 1948 in Michigan, USA. His vision was to improve the production of complex parts like helicopter blades, which required precision and efficiency. By collaborating with the .Many of the commands for the experimental parts were programmed "by hand" to produce the punch tapes that were used as input. During the development of Whirlwind, MIT's real-time computer, John Runyon coded a number of subroutines to produce these tapes under computer control. Users could enter a list of points and speeds, and the program would calculate the points needed . First, a shout out to what is widely considered the first machine tool: In 1775, John Wilkinson’s boring machine was the solution to accurately .

The story of CNC machining dates back to the 1940s and 1950s, originating from the need for high-precision machining for the defense and aerospace industries during and after World War . After the invention of the first CNC machine in the 1950s, CNC turning machines were developed, which revolutionized the manufacturing industry by providing a means of producing cylindrical parts with precision and . The First CNC Machine. The origin of the matter is how to machine the airfoil curve. Different airfoil curves will exhibit different lift, drag, stall angles, etc. at various airspeeds. Machining blades or airplane wings with specific . The first CNC machine, an experimental milling machine, was born out of a collaboration between John Parsons and Frank L. Stulen at Parsons Corporation in Traverse City, Michigan, in 1952. Their work centered around .

CNC BARON MILLING MACHINE; Jr. CNC Benchtop Milling Machine; Lathe 1440 CNC Machine Turning Center Catalog; CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining . CNC milling machines can perform a wide range of operations, such as drilling, slotting, and threading, making them versatile tools in the manufacturing process. . The development of the first CNC machine can be .Products Series | Milling Machine . LC-1 1/2 Series VERTICAL MILLING MACHINING ; MEEHANI TE CASTING STRUCTURE SPINDLE UNIT. R8,NST30, NST40 are available. Made from one piece of Ni-Cr alloy steel. Supported by two precision angular contact and one ball bearing to ensure rigidity. Inner taper was hardened and precision grounded. . There were several other reasons to opt for Computer Numerical Control (CNC) milling machines; the first one being the irregularity in data, output, and the products themselves. Once numerical programming was installed on a milling machine, it systematized their operations and made them faster, more precise and efficient than manual machining.

CNC (Computer Numerical Control) is the computer control of machine tools like mills, grinders, routers, and lathes. Investing in CNC milling machine requires some research and understanding as it can be such a complex machine, especially for first-time buyers.CNC milling machine. Luckily, TAICNC is here to guide you through what to keep in mind when shopping for your . Throughout its over 70-year history, the company has achieved numerous technological breakthroughs, including the development of China’s first CNC milling machines, automatic cold heading machines, heavy-duty floor-type milling and boring centers, and CNC multi-link press production lines.

Help choosing a first mill Help with choosing a mill Hi I am looking to buy my first mill. I am new to metal work and machining and am working on getting the basic stuff. . The PCNC 440 (00 to ~K) is a high end Hobby, low end professional unit, ready to run CNC machine. They have a 770 and 1100 that are bigger, more capable machines.TLDR: I have a salaried full time job as an engineer but I’m looking to acquire a small-ish CNC milling machine for my garage. At minimum I’ll use it to support various other hobbies and as a means of diving further into machining which I have already enjoyed for some time now, but I also have broader long-term ambitions of pursuing a side hustle with it in hopes of earning some .Samurai Machine tools have designed the first cnc machine with the capability of a second tool changer. Learn more Single ATC If you don't need 28 tools you can save money with the Single ATC. No ATC The ATC is a luxury not a necessity. With the pneumatic drawbar fitted as standard you can manually change tools in under 2 seconds.Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine. Our CNC milling process is capable of 3-axis (x,y and z), 4-axis and 5-axis (x,y,z, A and B) milling for high speed cutting of engineering-grade materials into product prototypes and precision end-use parts. The specific process is as follows:

Early Machine Tools. First, a shout out to what is widely considered the first machine tool: In 1775, John Wilkinson’s boring machine was the solution to accurately boring cylinders for steam .The OTMT 0T2213 mini mill is a small, compact benchtop milling machine with 1/2 HP and a 3.5” x 15” work table.. This benchtop milling machine has some great features that make it a useful addition to your workspace. For example, the head tilts 45 degrees from left to right, offering versatility and improved control for highly accurate cutting, milling, and engraving on your DIY . This is my first time buying a CNC machine. It cost 8600 to buy and repair, 800 for a rigger. Dont question my strength ever. Connect with me on Instagram: h.

There is a first time for everything. Well, this is my first post on this forum and it's about moving a CNC milling machine for the first time. I have bought a Kunzmann WF7 CNC which needs to be transported to my workshop. The machine seems to be very similar to a Mikron WF..C. The weight is about 2000kg. Haas is a huge name in the CNC industry and provides exceptionally high quality, professional standard machines around the world. It creates a huge variety of different milling machines, but the Modular Mini Mill .How does a CNC mill machine work? First, operators need to formulate processing technology and select processing parameters according to the technical requirements of the part shape, size, precision, and surface roughness. Then input the compiled processing program to the controller through manual programming or automatic programming with CAM .

In 1937, it was founded by Tsunezo Makino, and at the same time successfully developed Japan's first lift-table vertical milling machine. In 1953, the ultra-precision universal tool grinder was successfully developed. In 1958, the . CNC Milling Machines. Milling machines are the most common CNC equipment. They use a multi-point rotating cutting tool attached to a CNC-controlled spindle. Consequently, the spindle can move across multiple axes (3, 5, or more) to remove the material. . First, consider what kind of work material are you going to the machine. The physical and .Quality control and assurance verified by international quality assurance Systems including ISO 9000, CNC, JIS, DIN, UL, CSA, and CE, is final confirmation of the high standard of FIRST machines. Long chang has engineers with more than 10 years' experience in assembly or machining who now work in the Quality Control and Assurance team.When you’re buying your first CNC machine, there are a lot of things to consider. So, we put together a guide that includes everything you need to know from when you’re purchasing your machine to when you start making parts. . Mini CNC Vertical Mill with 16" x 14" x 15" travels. 40 Taper; 3 Axis; 8k RPM; 10 or 20 Tool Capacity CNY ONLY .

cnc machining g code

The CNC Baron Mill is durable and precise with a cast-iron body, with dovetail ways on the square column for vertical alignment. It is a versatile bench top mid-size CNC mill made for the user who needs both primary and secondary CNC machining applications.. The Baron CNC mill is a great investment for business owners who lower costs by creating their own parts.Designed to deliver precision and ease of operation, our First milling machines are equipped with essential features to help you master the art of milling. Since 1978, Modern Tools have been supplying reliable, high quality machine tools with outstanding experience, service and support Benchtop Milling Machines At CNC Masters, we offer several exceptional benchtop milling machines. Each one is a smaller CNC mill designed to deliver maximum power within a compact package, all at an affordable price. . The First CNC Machine. Preceding the MIT projects, Parsons Corporation, located in Traverse City in Michigan, had created a .

An important inflection point in the course of development. Let us look back at the magic process, it is because of CNC machine tools and CNC technology at the beginning of the birth of several major features – digital control ideas and methods, “software and hardware” combination, “Mechanical, electrical, and control information” multidisciplinary intersection, and .At Firstar Precision, our mission is to be the industry’s first authority for custom CNC-machined components through multi-axis milling and turning solutions. Located in Brunswick, Ohio, our facility’s full-service CNC machining department utilizes 4-axis and 5-axis CNC workstations with complete mill-turn capabilities – up to a 3.0 .

CNC BARON MILLING MACHINE; Jr. CNC Benchtop Milling Machine; Lathe 1440 CNC Machine Turning Center Catalog; CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining . CNC milling machines are the top-end option because they provide a high-precision solution to parts manufacturers. These machines are versatile and can handle various materials including metals like aluminum, steel, plastics, and even wood. . The Tutorials are easy to follow even for the first time CNC machinist.

types of cnc milling machines

most affordable cnc milling machines

compact cnc milling machine

A Box girder bridge is a multi-span steel truss bridge/prestressed concrete characterized by a very large, hollow box-shaped steel beam that is used to span between two piers. The Box girder bridge design consists of three sections: the main girder, the flanking beams and the deck.

first cnc milling machine|affordable cnc milling machines