metal sheet joints Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. Sheet metal is used to hold architectural and structural components together, so they keep their shape. Sheet metal cladding is used to cover large areas such as rooftops or partitions. Sheet metal is also frequently used in combination with other materials to .

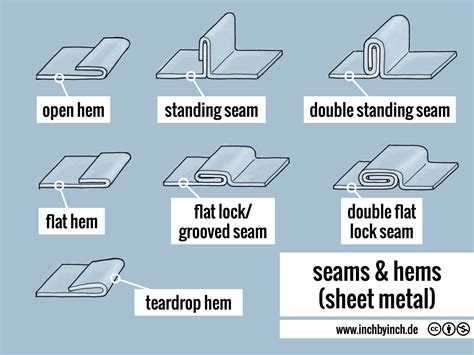

0 · types of sheet metal seams

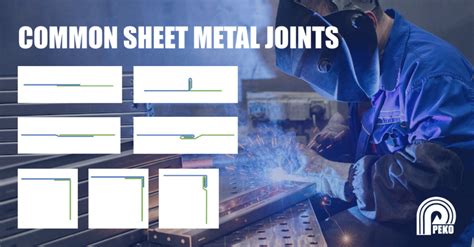

1 · types of sheet metal joints

2 · sheet metal overlap joint

3 · sheet metal joints pdf

4 · sheet metal clinching joint

5 · interlocking sheet metal joints

6 · interlocking sheet metal design

7 · how to attach sheet metal

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

Learn how sheet metal joints are made and used in the HVAC sheet metal industry to make air conditioning ductwork. Joints refer to the connection points or interfaces where two or more pieces of metal are brought together to form a larger structure or part. Joints can be classified based on their design and intended purpose, such as lap .

In this comprehensive guide, we will dive deeper into metal joining, exploring the welding and metal fabrication processes, their differences, applications, and their significance in modern industries.

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and .Multiply 1/8 by 2 1/2 and your answer will be 5/16 inch, which you will allow when laying out sheet metal for making the wire edge. Joints. The GROOVED SEAM JOINT (fig. 2-57) is one of the most widely used methods for joining light- and .

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. . Spot welding is a welding .Metal Joints. sheet metal joints - Google Search More. Metal Joints. Sheet Metal Bender. Sheet Metal Work. Metal Bender. Metal Shaping. Metal Fab. Metal Bending Tools. . Designing for Sheet Metal: What works on paper, doesn't .

types of sheet metal seams

Coated metal sheet for joint waterstop with adhesion to fresh concrete for waterproofing concrete construction joints. The Sika® MetalSheet FBV joint waterstop is a galvanized metal sheet with a special coating, applied on one side to increase its adhesion to fresh concrete.

The Sika® MetalSheet FBV joint waterstop is a galvanized metal sheet with a special coating, applied on one side to increase its adhesion to fresh concrete. This coating produces a durable watertight bond into the concrete structure. General Aproval Certificate (abP) Approved for use against water under pressure, up to a 20 m head .Understand Metal Joining Processes. Metal joining combines two or more metal components to create a unified structure. This process is crucial in various applications, from constructing buildings and bridges to manufacturing vehicles, machinery, and everyday appliances.By fusing metal pieces, engineers and fabricators can form solid and reliable connections that ensure .

The Sika® MetalSheet FBV joint waterstop is a galvanized metal sheet with a special coating, applied on one side to increase its adhesion to fresh concrete. This coating produces a durable watertight bond into the concrete structure. General Aproval Certificate (abP) Approved for use against water under pressure, up to a 20 m head .

Clinching involves creating an undercut to join two sheets (Meschut et al., 2022, Schramm et al., 2022).However, for a successful joint, both sheets need to be sufficiently ductile, which poses a significant challenge when trying to join metals with composites (Lambiase et al., 2016) and polymers (Lambiase, 2015).To enhance the ductility of composite and polymer .

types of sheet metal joints

To start a Sheet metal make joint operation: While in a Part Studio, click . Select the edges or side faces of intersection walls. This field requires two selections; two edges, two faces, or a face and an edge. Select one of the following joint types: Bend - Creates a curve between the faces/edges with a bend centerline and a radius. Keep the .

sheet metal joints - Google Search More. Metal Joints. Sheet Metal Bender. Sheet Metal Work. Metal Bender. Metal Shaping. Metal Fab. Metal Bending Tools. Sheet Metal Fabrication. Metal Workshop. Handmade Metal Spoons. Horse Shoe Hanger. . Designing for Sheet Metal: What works on paper, doesn't always work in the physical world as planned, for . Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal parts that will permanently or semi-permanently attach to one .

Metal Expansion Joints. Maximize your system’s resilience with our high-quality metal expansion joints. Designed to handle extreme pressures and temperatures, these joints include PTFE-lined, universally tied, in-line pressure-balanced, externally pressurized, Gimbal, and . The sheet metal bodies can be split up to individual sheet metal components and they can be joined to other components. However, only the moldings on the left and right side of the box can have a joint origin point at the center of the bend radius, because it has a flat side.

May 20, 2022 - Explore Nic Batchelor's board "Sheet Metal Joints" on Pinterest. See more ideas about sheet metal, metal, sheet metal work.Rebars can be cut and bended to different shapes used in various structures. Our rebar shapes in accordance with BS4466 1998, BS8666 2000, BS8666 2005.

The strength behind the TOX®-Joint. In the TOX®-Round Joint process, the material strain hardening in the neck area and the lacking of any notch effects produce the high retaining forces. . Sheet metal joining using only the parent . This video discusses the different commonly used connection joints found on Sheet Metal Duct work.Service construction company customers with a range of building materials. Buy wholesale sheet metal joints on Alibaba. Find sheet metal joints suited for construction. Get metal building materials deals now. Hemming is a sheet metal forming process where the edge is folded onto itself. Hems make a part more durable and improve its appearance. . The edge of one part may also be folded onto another part to create a joint. Hemming is usually done in two stages. The first stage creates an acute bend using acute tooling (V die) followed by a .

sheet metal overlap joint

This paper proposes a new joining by forming process to produce lap joints in metal sheets. The process combines partial cutting and bending with mechanical interlocking by sheet-bulk compression of tabs in the direction perpendicular to thickness. The lap joints are flat with all the plastically deforming material contained within the thickness of the two sheets partially . Lap joint welding is a process that involves overlapping two metal sheets and joining them along the overlapping area. It is commonly used to create strong and durable joints in sheet metal applications, such as automotive and aerospace components. Lap joint welding can be performed using various techniques, including MIG and TIG welding, each with its own .

Edge joints are commonly used in sheet metal work and for joining components where a flush edge is desired. They are versatile and can be used in various orientations depending on the welding process and joint configuration.For edge joints, several groove styles are commonly used: . Edge joints tend to be a weaker type of welding joint, so they are more commonly used in sheet metal. Two pieces of metal are held with their edges parallel and a seam is made along this joint. If an edge joint is required for bigger or more weight-bearing construction, it can be strengthened using filler metal.Sheet metal fits all “green” building materials measures, especially recycled content – Recycled content: steel = 25%; roofing copper = >75%; – Energy efficiency per Florida Solar Research = light-colored metal roofs VERY energy efficient Soldered sheet metal joints are “sustainable” and do not require continuous maintenance—unlike To start a Sheet metal make joint operation: While in a Part Studio, click . Select the edges or side faces of intersection walls. This field requires two selections; two edges, two faces, or a face and an edge. Select one of the following joint types: Bend - Creates a curve between the faces/edges with a bend centerline and a radius. Keep the .

type of joint includes the application of an appropriate sealant at each joint. Figure 15-1 The Basic Lap Joint . A variation of the lap joint is the . nested. lap, which is utilized by many types of ribbed metal panels. A nested lap joint overlaps the adjacent panel, but also covers or "nests" the lower panel rib within the rib of the lapping . Additionally, using backing bars or supports can help manage distortion and ensure the flatness of the welded joint. By meticulously preparing sheet metal for butt welding, fabricators and welders set the stage for achieving precise, strong, and flawless welds. Attention to detail in cleaning, fit-up, and distortion control is essential for .

are milltronic partner cnc machines any good

argenbright national sheet metal works inc

If an IRA conversion contribution or a rollover from a qualified plan is made to a Roth IRA that is later revoked or closed, and a distribution is made to the taxpayer, enter the gross distribution .

metal sheet joints|interlocking sheet metal joints