cnc machines benefits Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive. We offer a wide range of Box Locks, Drawer & Cupboard Locks online. Available in a selection of sizes, visit our site to find the right one for you!

0 · disadvantages of cnc machines

1 · disadvantages of cnc

2 · cnc punching machine disadvantages

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · advantages of cnc milling machine

Below, we explore the top options to help gain high-quality results in any fabrication process. 1. CNC Machines. CNC (Computer Numerical Control) machines use computer technology to control machine tools, producing more precise cuts. Their components are quite complicated, including the following:

This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique . Advantages of Using CNC Machinery. As with any manufacturing process that has lasted for decades, CNC machining offers numerous advantages over other part creation methods. Using computer control allows you to get .Understanding the Fundamentals and Benefits of CNC Machining. Explore the comprehensive guide to CNC machining, a high-tech manufacturing process driven by computer software for precision and efficiency.

Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive. Benefits. Common Challenges. Can a CNC Machine Cut Metal? The Future of CNC Machining. The Basics of CNC Machining. Definition and History. CNC machining is a subtractive manufacturing process in which a .

CNC machining involves the use of various materials to manufacture high precision components. Usual metals include aluminium, stainless steel and alloys as well as plastics like ABS or polycarbonate. Further wood, composites .CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits .

Explore the world of CNC technology, its benefits, and applications in modern manufacturing. Dive into how it shapes industries through precision and automation. . G-code language controls the movement and functioning . As with any manufacturing process, the unique advantages of CNC machining inform the kind of applications for which it can be used. However, the benefits of CNC are desirable in virtually any industry. They are suitable for many parts and products. Since CNC machines can process almost any type of material, their applications are near limitless. 10 Benefits of CNC Machining 1. CNC Machining Reduces Material Wastage On Floor. CNC machining is an effective process in terms of minimizing wasted material. When designing parts, the faulty cuts are likely to be minimal. Accuracy leads to less likelihood of having several faulty products, therefore optimizing the material usage.

Unveiling the Hidden Gems: Exploring the Unknown Benefits of 5-Axis Machining. March 26, 2024. Read More. Unveiling the Power of 5-Axis CNC Machining: Key Benefits and Advantages. February 29, 2024. Read More. Unveiling the Speed Titan: Brother U500xd1 5-Axis CNC Machine Tool. February 16, 2024. Read More In addition to its current benefits, the future of CNC machining looks promising with the emergence of innovative technologies and advancements. One such development is the increased connectivity of CNC machines. By incorporating internet connectivity, manufacturers can remotely monitor and control CNC machines, leading to enhanced operational . CNC machining plastic is one of the popular machining processes across different industries. Manufacturers often make machined parts for diverse applications because of plastic material availability. Besides, the CNC machining process is more accurate and fast and offers the preferred tolerances in plastic machined parts since it uses computer numerical control to .

Matching the right machine with the appropriate metal size and strength is crucial for achieving desired results. CNC bending machines offer numerous benefits, including: Cost Reduction: By automating the bending process, CNC machines help reduce labor costs and minimize material waste. This leads to significant cost savings for manufacturers. For small firms and startups, traditional machining technologies can be expensive and time-consuming. However, CNC prototype machining offers businesses or manufacturing companies that want to produce parts and components a quick, cost-effective way that maintains precision and quality. One major reason why CNC prototype machining is becoming the first .

In the world of stone fabrication, CNC (Computer Numerical Control) machines have revolutionized the industry, providing numerous benefits that enhance efficiency and productivity. CNC stone machines utilize advanced technology and automation to streamline the cutting, shaping, and polishing processes of stone materials.

A CNC machine is an automatic power tool with computer controlled for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. . can create benefits for users, and provide a guarantee for safe use; it has advanced simulation automation technology to give The user provides the .Apart from a number of other benefits, the main benefits of the CNC machines are: superior automation, accuracy and flexibility. The process of the CNC machines is fully automated. The need of the operators can be reduced to minimum or it can be totally eliminated. The CNC machines offer highly accurate jobs which may be very difficult and time consuming for the . The sound of chips hitting the machine has people flocking to the Ibarmia stand at AMB 2024!! Whether it’s the T series or the Z series, Ibarmia’s Gen2 models have so many different options you wouldn’t normally see at any exhibition. From standard milling and turning all the way to skiving, eccentric turning, elliptic turning, [.]

disadvantages of cnc machines

Due to automation, lack of human error, and the ability of machines to run 24/7, there are many CNC machining benefits. What is CNC Machining? CNC machining is a manufacturing process that utilizes a programmed .

Benefits of our engraving machines and CNC milling machines for jewelry, stamps, signs, 3D engraving and micromachining. In this blog post, we’ll explore the myriad benefits of milling machines, including their advanced CNC variants, while comparing them to their manual counterparts like manual knee mills and bridge milling machines. 1. . CNC machines can be programmed for quality control checks during production, lowering defect rates and ensuring high-quality parts. This focus on quality assurance enhances customer satisfaction and strengthens brand reputation, making CNC machining a preferred choice for many manufacturers. Benefits of CNC Machining for Automotive and Aerospace

The Benefits of CNC Machining for In-Demand Industries. Industry leaders view CNC machining as a vital aspect of the modern economy. Various processes create critical components of our everyday lives. Imagine an airport without airplanes or a highway without cars. That’s how the world would look without precision machining.

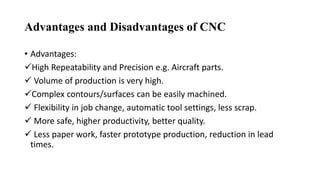

Types of CNC Machines. The most common types of CNC machines are those that use cutting tools to remove excess material from the workpiece. While there are CNC machines that employ water jet cutting and electrical discharge machining (EDM) operations, this guide will focus on the five most common categories in the following list, divided into two basic . CNC machines have revolutionized manufacturing by improving machining quality and production speed to keep up with the ever-growing demand for complex machine parts. These machines offer various advantages over traditional machining tools. However, there are some disadvantages as well to CNC Machining. So, what are the benefits of CNC Machining? Outsourcing CNC machining involves collaborating with an external specialized CNC shop to perform precision machining operations with CNC tools and machinery. This strategic approach ensures the production of different CNC parts with tight tolerances, advanced capabilities, and cost efficiency, eliminating the need for significant in-house investment. . Benefits: Increased Machine Utilization: CNC machines can run continuously, 24 hours a day, without operator breaks, and robots can operate continuously. Consistency and Precision: Automated handling also ensures that each part will be loaded and positioned correctly, minimizing production errors and unwanted scrap rates.

Benefits of CNC Machining. Some benefits of CNC systems are: Reduction in Cost. CNC machines are cost-effective. They reduce production costs through precision manufacturing. Energy consumption is reduced due to enhanced production efficiency, scalability, and less material waste. This results in cheaper operating costs. Benefits of Stainless Steel for CNC Machining. Stainless steel is a commonly used CNC Machining material across industries. Here are some of the benefits of using stainless steel for your CNC machining projects. Corrosion Resistance. Stainless steel is naturally corrosion-resistant. Hence, stainless steel machined parts can withstand rust and .

With desktop CNC machines, space is no longer a limitation to enjoying the benefits of a CNC machine. Less expensive. As they are smaller, desktop CNC machines will necessarily have less powerful motors, less sophisticated systems, and a smaller build platform. This makes them a lot more affordable than full-sized CNC machines.

Computer Numerical Control (CNC) machines have reshaped the manufacturing industry, offering a myriad of benefits and capabilities. These automated marvels harness computer programs and precise instructions to govern cutting tools, delivering unparalleled accuracy .

disadvantages of cnc

This metalworking process is used extensively to manipulate the size and shape of sheet metal. Notching typically requires the use of a punch press, which is responsible for removing material from the outer edges of a workpiece.

cnc machines benefits|advantages of cnc milling machine