difference between using metal and plastic gang box 15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with . Metal Supermarkets offers a variety of shapes and grades of stainless steel for sale, cut to size, including 17-4, 303, 304, 316, 416 and 440C. Select from one of the available shapes below to get started. Or contact your closest store for assistance with metal sourcing.

0 · wiring plastic electrical boxes

1 · plastic vs metal electrical boxes

2 · plastic outlet box vs metal

3 · plastic or metal electrical boxes

4 · plastic junction boxes electrical lowe's

5 · plastic electrical outlet boxes types

6 · metal versus plastic electrical box

7 · junction box vs outlet

Since 1938 G&H has been a supplier of structural enclosures, sheet metal fabrication, and welding services. We are a custom sheet metal job shop specializing in prototypes, short-run & contract metal product manufacturing, offering specialty welding, precision fabrication, & .

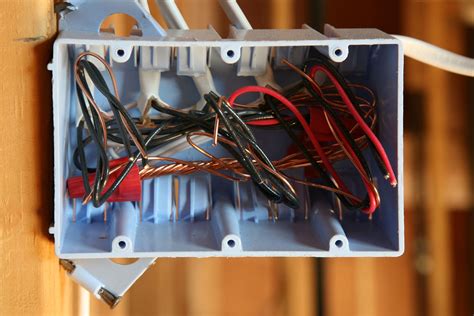

To gang electrical boxes means to attach two or more boxes to create a single box. This provides the user with the flexibility to construct boxes as needed. Metal boxes are strong, plus they provide a strong attachment to the stud. When attachment to the stud is a major .15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .

BX cable is a type of metal-clad, armored cable. Learn the basics of armored BX .Using Plastic Push-In Connectors . The newcomer on the block is the plastic . Plastic boxes are lightweight, easy to work with, and suitable for non-metallic cables. They are a popular choice for DIYers. On the other hand, .

Use plastic boxes when: There are non-metallic (NM) cables leading in or out of the box. Metal-sheathed wiring relies on bonding with the metal electric box for grounding and should not be used in plastic boxes. Plastic boxes are cost-effective and lightweight. They are widely used for standard residential and low-voltage applications. Metal boxes are durable, fire-resistant, and good for grounding. They are used in demanding . That’s why it’s essential to understand the two main types of junction boxes: plastic and metal. Each has its advantages. Plastic boxes are lightweight and easy to install, perfect . Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic junction boxes are not so .

Plastic new work boxes are commonly used with non-metallic cable wiring. They offer quick installation and are good for most residential applications. Metal new work boxes are preferred when using metal-clad . To gang electrical boxes means to attach two or more boxes to create a single box. This provides the user with the flexibility to construct boxes as needed. Metal boxes are strong, plus they provide a strong attachment to the stud. When attachment to the stud is a major worry, choose a metal box.

Plastic boxes are lightweight, easy to work with, and suitable for non-metallic cables. They are a popular choice for DIYers. On the other hand, metal boxes offer unmatched strength, durability, and compatibility with metal-sheathed cables or conduits, making them ideal for specific applications. Use plastic boxes when: There are non-metallic (NM) cables leading in or out of the box. Metal-sheathed wiring relies on bonding with the metal electric box for grounding and should not be used in plastic boxes. Plastic electrical boxes, including single gang boxes, have fire ratings. When it comes to fire classification, Carlon’s blue nonmetallic outlet boxes, except for old work boxes, are classified for walls with a fire rating of two hours or less.

Plastic boxes are cost-effective and lightweight. They are widely used for standard residential and low-voltage applications. Metal boxes are durable, fire-resistant, and good for grounding. They are used in demanding environments and critical installations. That’s why it’s essential to understand the two main types of junction boxes: plastic and metal. Each has its advantages. Plastic boxes are lightweight and easy to install, perfect for most residential homes. On the other hand, metal boxes are .

Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic junction boxes are not so sturdy, so not suitable for outside areas. Plastic new work boxes are commonly used with non-metallic cable wiring. They offer quick installation and are good for most residential applications. Metal new work boxes are preferred when using metal-clad cables. These provide better grounding and bonding capabilities.Metal boxes and plastic boxes are two common options available, each with its own set of advantages and disadvantages. In this blog, we'll explore the pros and cons of both metal and plastic boxes, helping you make an informed decision for your electrical needs.

wiring plastic electrical boxes

There are two types of junction boxes in common use today: metal junction boxes and plastic junction boxes. Both have their own advantages, and both are useful for certain applications. For many applications, the biggest advantage of a metal junction box is its durability. To gang electrical boxes means to attach two or more boxes to create a single box. This provides the user with the flexibility to construct boxes as needed. Metal boxes are strong, plus they provide a strong attachment to the stud. When attachment to the stud is a major worry, choose a metal box.

electrical outlet extension box

Plastic boxes are lightweight, easy to work with, and suitable for non-metallic cables. They are a popular choice for DIYers. On the other hand, metal boxes offer unmatched strength, durability, and compatibility with metal-sheathed cables or conduits, making them ideal for specific applications. Use plastic boxes when: There are non-metallic (NM) cables leading in or out of the box. Metal-sheathed wiring relies on bonding with the metal electric box for grounding and should not be used in plastic boxes.

Plastic electrical boxes, including single gang boxes, have fire ratings. When it comes to fire classification, Carlon’s blue nonmetallic outlet boxes, except for old work boxes, are classified for walls with a fire rating of two hours or less. Plastic boxes are cost-effective and lightweight. They are widely used for standard residential and low-voltage applications. Metal boxes are durable, fire-resistant, and good for grounding. They are used in demanding environments and critical installations. That’s why it’s essential to understand the two main types of junction boxes: plastic and metal. Each has its advantages. Plastic boxes are lightweight and easy to install, perfect for most residential homes. On the other hand, metal boxes are . Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic junction boxes are not so sturdy, so not suitable for outside areas.

Plastic new work boxes are commonly used with non-metallic cable wiring. They offer quick installation and are good for most residential applications. Metal new work boxes are preferred when using metal-clad cables. These provide better grounding and bonding capabilities.Metal boxes and plastic boxes are two common options available, each with its own set of advantages and disadvantages. In this blog, we'll explore the pros and cons of both metal and plastic boxes, helping you make an informed decision for your electrical needs.

plastic vs metal electrical boxes

plastic outlet box vs metal

We provide metal stamped parts and additional stamping solutions for all complex applications in a timeframe that promises client success. We’re able to provide short-run metal parts and medium run metal parts faster than the competitor because of our in-house tooling system.

difference between using metal and plastic gang box|wiring plastic electrical boxes