ball screw cnc machine Discover Sherline’s CNC-Ready Ball Screw Mills, designed to provide exceptional precision and performance for your CNC projects. Featuring advanced ball screw technology, these mills . Open up the clamping tab. Old work electrical boxes made from PVC use an .

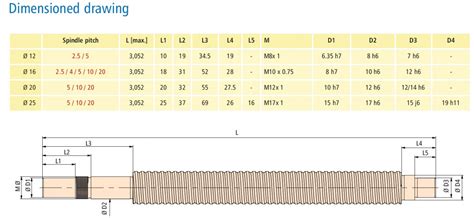

0 · standard ball screw sizes

1 · cnc router with ball screws

2 · ball screw vs belt drive

3 · ball screw size guide

4 · ball screw size chart

5 · ball screw selection guide

6 · ball screw manufacturing process

7 · anti backlash ball screw nuts

What is an electrical junction box used for? An electrical junction box is used for several purposes, including: Containing and protecting electrical connections, such as wire splices and wire terminations. Preventing contact with live wires, which reduces the risk of electrical shocks and fires.

Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the . The ULTIMATE Bee is a solid and reliable CNC Machine, Featured by the HGR Linear Rails and SFS Series Quiet Transmission Ball Screws! It is our second CNC Machine .

Ball screws have rolling friction, like ball bearings, and so require less power and have longer life. This is how ball screws are fixed on the machine. You can see the ball screw, .Discover Sherline’s CNC-Ready Ball Screw Mills, designed to provide exceptional precision and performance for your CNC projects. Featuring advanced ball screw technology, these mills .

Ball Screw Driven System: The XE-PRO uses 1204 ball screws on the XYZ axes for precise cutting and carving. It also uses the dual linear rails on Z axis to improve the rigidity of the machine. Unique Upgradable Design: Exclusive and .Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a .

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, . A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. Rack and Pinion Advantages :

What is a ball screw and why is the most common type used in CNC milling machines? The spindle is a mechanism designed to transmit motion to certain parts of the .

Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications. While ball screw technology has come a long way over the past couple of decades, there are still a lot of widespread misconceptions about it and how it pertains to CNC work. Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router.The ULTIMATE Bee is a solid and reliable CNC Machine, Featured by the HGR Linear Rails and SFS Series Quiet Transmission Ball Screws! It is our second CNC Machine based on the initial WorkBee design lineage, which is characterised by the use of C-Beam Extrusions and the rectangular-shaped Y-Plates. Ball screws have rolling friction, like ball bearings, and so require less power and have longer life. This is how ball screws are fixed on the machine. You can see the ball screw, the nut, and.

Discover Sherline’s CNC-Ready Ball Screw Mills, designed to provide exceptional precision and performance for your CNC projects. Featuring advanced ball screw technology, these mills minimize backlash and enhance accuracy, making them ideal for intricate machining tasks.

house stark metal

standard ball screw sizes

Ball Screw Driven System: The XE-PRO uses 1204 ball screws on the XYZ axes for precise cutting and carving. It also uses the dual linear rails on Z axis to improve the rigidity of the machine. Unique Upgradable Design: Exclusive and innovative design for .Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design.

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, ball screws offer significantly reduced friction, leading to smoother, more accurate movements. Here’s why they’re so crucial: A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. Rack and Pinion Advantages : What is a ball screw and why is the most common type used in CNC milling machines? The spindle is a mechanism designed to transmit motion to certain parts of the milling machine or other heavy industrial machines through a .

Provide an overview of the different types of ball screws commonly used in CNC machines, such as precision ground ball screws, rolled ball screws, and miniature ball screws. Explain the differences in their construction, performance, and applications.

While ball screw technology has come a long way over the past couple of decades, there are still a lot of widespread misconceptions about it and how it pertains to CNC work. Here’s a breakdown of how ball screw technology works and why it delivers better results for your CNC router.The ULTIMATE Bee is a solid and reliable CNC Machine, Featured by the HGR Linear Rails and SFS Series Quiet Transmission Ball Screws! It is our second CNC Machine based on the initial WorkBee design lineage, which is characterised by the use of C-Beam Extrusions and the rectangular-shaped Y-Plates. Ball screws have rolling friction, like ball bearings, and so require less power and have longer life. This is how ball screws are fixed on the machine. You can see the ball screw, the nut, and.

Discover Sherline’s CNC-Ready Ball Screw Mills, designed to provide exceptional precision and performance for your CNC projects. Featuring advanced ball screw technology, these mills minimize backlash and enhance accuracy, making them ideal for intricate machining tasks.Ball Screw Driven System: The XE-PRO uses 1204 ball screws on the XYZ axes for precise cutting and carving. It also uses the dual linear rails on Z axis to improve the rigidity of the machine. Unique Upgradable Design: Exclusive and innovative design for .

Ball Screw systems create improved wear and tear levels. The Ball Screws on our CNC router tables consist of a sealed bearing with many re-circulating ball bearings evenly spaced and constantly lubricated as it moves through a channel design.

At the heart of any CNC machine is its ability to convert rotational motion into linear motion with absolute precision. This is where ball screws come into play. Unlike traditional lead screws, ball screws offer significantly reduced friction, leading to smoother, more accurate movements. Here’s why they’re so crucial: A rack and pinion is a type linear actuator that is used to drive an axis on a CNC machine. Competing systems include belt drives and ball screws. Rack and Pinion Advantages :

cnc router with ball screws

house of metal lyrics

The most common types of electrical boxes include junction boxes, outlet boxes, switch boxes, and ceiling boxes. Junction boxes are used to connect wires and cables, while outlet boxes are used to house electrical outlets.

ball screw cnc machine|standard ball screw sizes