cnc milling machine how it works How Does CNC Milling Work? CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. Cat Litter Essentials at Target. Clumping, clay, & natural litters. Find odor control & dust control options. Free shipping on orders $35+.

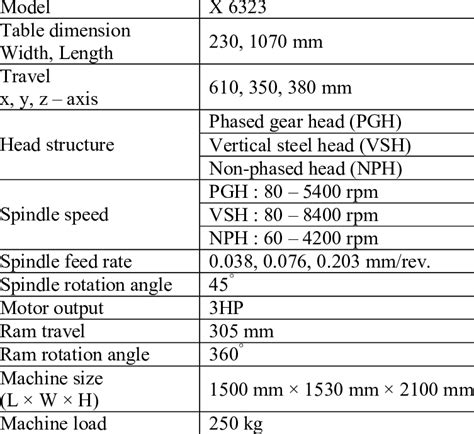

0 · specifications of cnc milling machine

1 · milling process step by

2 · introduction to cnc milling machine

3 · cnc milling tutorial

4 · cnc milling explained

5 · cnc milling diagram

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

Get information, directions, products, services, phone numbers, and reviews on VTS Sheetmetal Specialist in Anaheim, undefined Discover more Fabricated Plate Work (Boiler Shops) companies in Anaheim on Manta.com

Milling is a manufacturing method using a rotating cylindrical cutting tool to remove materials from the workpiece and create a wide .November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. .How Does CNC Milling Work? CNC milling is a subtractive manufacturing process that uses computer-controlled, multi-point, rotary cutters to remove material from a workpiece and produce a custom-designed part or product. CNC Milling Process: This entails the use of computer numerical control (CNC) machinery to accurately remove material from a workpiece. The essential principles involve translating a digital design into numerical codes .

At its core, CNC milling revolves around a straightforward principle: using computer-controlled machinery to cut, shape, or modify materials. Unlike manual methods, where a craftsman would laboriously cut and shape .

CNC Control (included with the machine): receives the instructions from the CAM and executes the movement orders of the moving parts of the milling machine according to these instructions. STEP 3: CNC Milling Machine Ready. When .

What is CNC Machining? CNC machining is a type of automated machining process that uses computer numeral control technology to shape an object or a part by removing material from a workpiece until the desired shape is achieved.. CNC stands for Computer Numerical Control. It means utilizing computerized software to control how a machine moves and operates.What Is a Milling Machine and How Does It Work? Milling is a common form of machining in the manufacturing industry. A milling machine works by using a rotary cutting tool to remove material from a workpiece to create different .

In this article, we will explore the basics of CNC machining, the axes system used in 5-axis CNC milling, the tools and machines used, and how 5-axis CNC milling works. We will also discuss the benefits and limitations of this technology and its future prospects. So, let’s dive in and learn more about 5-axis CNC milling and how it works. CNC milling machines can work with a wide range of materials, including metals like aluminium and steel, as well as plastics and composites. What is a CNC milling machine? A milling machine manufactures high-quality parts to a high level of detail and finish. CNC milling machines use rotary tools to cut away at the material, with instructions .Quick info: The CNC milling machine works on different materials. These include glass, wood, metal, and more. The machine’s precision won’t vary, no matter what material you use as a workpiece. That’s why CNC milling is considered more reliable than other types of milling.

CNC milling is a machining process that combines computer numerical control machining systems and a multi-point cutting tool or milling cutter. As one type of CNC machining, it involves mounting the workpiece on a machine bed and cutting materials from a solid block to produce products made of glass, metal, plastic, wood and more specialized materials. A 3-axis CNC milling machine consists of several key components that work together to create precise and accurate parts and components. Some of the main components of a 3-axis CNC milling machine include: . How 3-axis CNC machining works. 3-axis CNC machining involves several steps, from the design of the part in CAD software to the actual .How do the CNC Machines Work? A majority of CNC machines require software programs to run. They employ CAM (Computer Aided Machining). CAM is a software package that creates Numerical Control (NC) codes and tool paths. These paths are based on 3D computer models. It’s important to note that the CAM doesn’t run the CNC machine.CNC milling is a type of CNC machining process that uses milling machines, equipped with rotary cutting tools and controlled by computer numerical control technology, to perform precise movements and tasks. CNC milling makes it possible to take a digital design of an object and produce it in a physical form from raw materials.

Automatic CNC milling machines; These are used for processing very complex profiles or surfaces. The automatic milling machines are equipped with a probe device that keeps always adherent to the model (copying cutters), guiding the milling head in its movements. . One thought on “How milling machine works” Thomas says: July 24, 2020 at 9: . Like a manual milling machine, a CNC mill works with a round rotating tool that cuts into a block of material. A platform attached to the machine holds and moves the material as needed to meet the cutting tool. A CNC mill differs from a manual mill in how the operator directs it to cut a piece. Instead of manually controlling the machine, an .

#cncmachining In this video, you’re going to learn what CNC machining is and how it works. After watching you will have a good understanding of CNC machining.

Machine Preparation: Up next is the arrangement of the CNC milling machine with the requisite tools and work materials. This involves the selection and fitting of suitable drill bits, designating the initiation points, and firmly placing the workpiece on the machine platform.

In this CNC milling machine tutorial, we will provide a comprehensive guide on how to use a CNC milling machine. We will cover the basics of CNC milling mach. In this video learn how a CNC milling machine operates. For more information, check out our other videos on CNC Machines:https://youtu.be/QR3VRBCUAnwhttps:/.

used multicam cnc parts

A CNC milling machine is a high-tech automation solution for drilling, cutting, and shaping blanks. Learn all about it and how it can upgrade your shop floor. . Precision movement and cutting: With the instructions in place, the CNC milling machine sets off to work. The spindle revs up, the cutting tool gets into position, and the machine . A vertical milling machine, also known as a vertical machining center or CNC vertical milling machine, is a versatile machining tool. Its main feature is a vertically oriented spindle, which can fix and rotate cutting tools, allowing them to .

A CNC Milling Machine is a machine that uses a spinning cylindrical cutter to drive along several axes and cut slots, gaps, and information in material to produce a vehicle or mechanical component. . and machine work keeping capacity restrict Low component widths and maximum part heights are examples of different designs, and the presence and . CNC milling is a fundamental aspect of modern manufacturing. The process involves the use of a CNC milling machine, which operates by interpreting coded instructions to execute complex milling tasks with precision and efficiency. The Mechanics of CNC Milling. The mechanics of a CNC mill are designed to translate digital data into physical motion. Conversion: For all our non-U.S. friends, 1 Thou is equal to .0254 mm. TITANS of CNC: Academy: http://bit.ly/2J6mvhOAutodesk Free Trials: Inventor - https://. 3-axis CNC machines are the simplest type and operate on the X, Y, and Z axes. They are commonly used for producing flat or simple curved parts, such as those found in furniture, signage, and electronics. 4-axis CNC machines add the A-axis, or rotational axes, to the three axes of the 3-axis machine.

The milling process starts with positioning the workpiece on the CNC machine’s work surface or holding device. Milling tools are then installed into the machine’s spindle. Depending on the programmed requirements from CAD, the milling can proceed in either a horizontal or vertical direction. . CNC milling machines must be manufactured to . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages computerized systems to control the movement and operation of the cutting tools with extreme precision.How Do CNC Milling Machines Work? CNC Milling machines are advanced equipment handled by a computer numerical control system. The milling machines cut and shape the mounted workpiece with the help of CAD-processed design. Since the computer program guides these machines, their operation is synchronized and error-free. CNC milling machines are .

The exact movements that this code controls depends on the type of CNC machine that is being used. Let’s take a look at some of the most common CNC machines in use today, and how they work: Types of CNC Machines #1 CNC milling machines. CNC milling is one of the most common types of CNC machining, known for its great accuracy and tolerances .

specifications of cnc milling machine

A CNC milling machine is a type of machine tool that uses computer numerical control (CNC) technology to automate the machining process. CNC milling machines are widely used in the manufacturing industry to produce high-precision components for various applications.

used metal fabrication equipment canada

used metal roofing sheets near me

used metal tool box

used cnc machine dealers

Bus Sheetmetal Please select your Model Bus, (Delivery - Micro Bus Deluxe) Pick Up, (Single Cab) CUST SERVICE | COLOR CHARTS | ABOUT WW | CATALOG | SPEED CART

cnc milling machine how it works|basics of the cnc mill