aluminum vs sheet metal Even though there are plenty of benefits aluminum provides, there are some significant drawbacks as well. Some of the biggest drawbacks of using aluminum include: 1. While it is . See more To remove the fusebox, first disconnect the battery leads. Then remove the front knee panel below the steering wheel for better access. Then you lay on the floor to look up from below. The fuse box is attached by 2 screws.

0 · steel vs aluminum mechanical properties

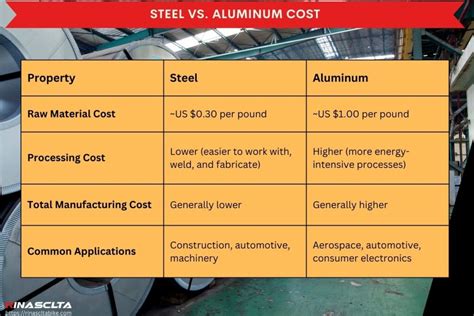

1 · steel vs aluminum cost difference

2 · is steel heavier than aluminum

3 · is aluminum as strong steel

4 · how strong is aluminum

5 · differences between aluminum and steel

6 · aluminum vs steel sheet equivalent

7 · aluminum vs stainless steel strength

Omni Metalcraft Corp is a manufacturing company based in Alpena, MI, specializing in the production of metal components and products. With a focus on quality craftsmanship and precision engineering, the company serves a variety of .

One of the first options you have probably heard about is aluminum. It has been used for a long time, and one of the most common types of aluminum is 3003. It is frequently used in manufacturing. Some of the most important benefits of aluminum include: 1. It is generally less expensivewhen compared to steel, . See moreEven though there are plenty of benefits aluminum provides, there are some significant drawbacks as well. Some of the biggest drawbacks of using aluminum include: 1. While it is . See more

There are a lot of people who enjoy using steel for metal fabrication projects because it is durable, reliable, and battle-tested. Some of the biggest benefits of going with steel include: 1. It is . See more

Some of the biggest drawbacks of going with steel include: 1. It is significantly more expensivethan most types of aluminum. The cost can vary depending on the exact metallic makeup, but . See moreElectrical Conductivity: Aluminum (37.7 million S/m) vs Steel (6.99 million S/m) Yield Strength: Aluminum (7-11 MPa) vs Steel (250-1000 MPa, depending on grade) These differences .

Aluminum, of course, is lighter than steel. Therefore, aluminum sheet metal weighs less than its steel counterpart as well. In addition to being . Generally speaking, steel is stronger than aluminum. That said, once the lighter weight of aluminum is factored into the equation, aluminum comes out on top with a superior strength-to-weight ratio. Identifying which .

steel vs aluminum mechanical properties

Aluminum is highly corrosion-resistant because it forms a protective oxide layer that shields the underlying metal from environmental elements. This characteristic makes aluminum ideal for applications where .

Is it Cheaper to Use Aluminum or Steel Sheet Metal? Along the same lines as weight and strength, a budget often factors in when designing parts. In general, mild steels (1008 and A36) are less expensive than lower . When you compare the strength, weight, corrosion resistance, and cost of aluminum vs steel, you will quickly see why Eagle Aluminum relies on the many advantages of using aluminum for custom extrusions and stock profiles. .

Since not all aluminum grades have the same properties, the most important question when choosing an alloy is: How do you want to use your aluminum sheet metal? Here are some factors to keep in mind: Strength. Do .

One of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above.. Another difference between Aluminum Plate .

steel vs aluminum cost difference

20 ta’ Fra 2024 When comparing cast aluminum to other metals, such as cast iron and steel, we find distinct differences in their properties in the context of aluminum casting and .

Pros and cons of aluminum sheet metal vs. steel sheet metal. Learn about each types and how each can benefit the type your project.Electrical Conductivity: Aluminum (37.7 million S/m) vs Steel (6.99 million S/m) Yield Strength: Aluminum (7-11 MPa) vs Steel (250-1000 MPa, depending on grade) These differences highlight why material selection is so crucial. Each metal’s unique properties make it suited for different applications. Aluminum vs. Steel: Quick Comparison

Aluminum, of course, is lighter than steel. Therefore, aluminum sheet metal weighs less than its steel counterpart as well. In addition to being lightweight, aluminum sheet metal offers a high level of protection against corrosion. It’s frequently used in applications where moisture is a problem, such as the production of boats. Generally speaking, steel is stronger than aluminum. That said, once the lighter weight of aluminum is factored into the equation, aluminum comes out on top with a superior strength-to-weight ratio. Identifying which metal has the better strength for your application will depend on your design’s flexibility.

Aluminum is highly corrosion-resistant because it forms a protective oxide layer that shields the underlying metal from environmental elements. This characteristic makes aluminum ideal for applications where corrosion resistance is a priority, without additional protective coatings. Is it Cheaper to Use Aluminum or Steel Sheet Metal? Along the same lines as weight and strength, a budget often factors in when designing parts. In general, mild steels (1008 and A36) are less expensive than lower grades of aluminum (5052 and 6061), but high strength steels (4130) are more expensive than higher strength aluminum (7075).

When you compare the strength, weight, corrosion resistance, and cost of aluminum vs steel, you will quickly see why Eagle Aluminum relies on the many advantages of using aluminum for custom extrusions and stock profiles. Determining whether aluminum is stronger than steel involves a nuanced analysis of its overall strength. Since not all aluminum grades have the same properties, the most important question when choosing an alloy is: How do you want to use your aluminum sheet metal? Here are some factors to keep in mind: Strength. Do you need a high strength-to-weight ratio? Formability. Will you be shaping or bending? Machining.One of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above.. Another difference between Aluminum Plate and sheets has to do with the distinct applications for which they are used.20 ta’ Fra 2024 When comparing cast aluminum to other metals, such as cast iron and steel, we find distinct differences in their properties in the context of aluminum casting and manufacturing. This is particularly evident in areas like density, tensile strength, and.

is steel heavier than aluminum

Pros and cons of aluminum sheet metal vs. steel sheet metal. Learn about each types and how each can benefit the type your project.Electrical Conductivity: Aluminum (37.7 million S/m) vs Steel (6.99 million S/m) Yield Strength: Aluminum (7-11 MPa) vs Steel (250-1000 MPa, depending on grade) These differences highlight why material selection is so crucial. Each metal’s unique properties make it suited for different applications. Aluminum vs. Steel: Quick Comparison

Aluminum, of course, is lighter than steel. Therefore, aluminum sheet metal weighs less than its steel counterpart as well. In addition to being lightweight, aluminum sheet metal offers a high level of protection against corrosion. It’s frequently used in applications where moisture is a problem, such as the production of boats. Generally speaking, steel is stronger than aluminum. That said, once the lighter weight of aluminum is factored into the equation, aluminum comes out on top with a superior strength-to-weight ratio. Identifying which metal has the better strength for your application will depend on your design’s flexibility. Aluminum is highly corrosion-resistant because it forms a protective oxide layer that shields the underlying metal from environmental elements. This characteristic makes aluminum ideal for applications where corrosion resistance is a priority, without additional protective coatings. Is it Cheaper to Use Aluminum or Steel Sheet Metal? Along the same lines as weight and strength, a budget often factors in when designing parts. In general, mild steels (1008 and A36) are less expensive than lower grades of aluminum (5052 and 6061), but high strength steels (4130) are more expensive than higher strength aluminum (7075).

When you compare the strength, weight, corrosion resistance, and cost of aluminum vs steel, you will quickly see why Eagle Aluminum relies on the many advantages of using aluminum for custom extrusions and stock profiles. Determining whether aluminum is stronger than steel involves a nuanced analysis of its overall strength. Since not all aluminum grades have the same properties, the most important question when choosing an alloy is: How do you want to use your aluminum sheet metal? Here are some factors to keep in mind: Strength. Do you need a high strength-to-weight ratio? Formability. Will you be shaping or bending? Machining.One of the main differences between Aluminum Plate and sheets is that sheet metal is under .249” thick, while plate metal is .250” and above.. Another difference between Aluminum Plate and sheets has to do with the distinct applications for which they are used.

home theatre 5.2 connection junction box

home depot steel sheet metal

Braces, brackets, and hardware are used to assemble and stabilize standard metal shelving units. These parts are used to replace parts on an existing shelving unit, expand an existing shelving .

aluminum vs sheet metal|differences between aluminum and steel