cnc machine reamer Solid carbide reamers for highest feed rates, maximum chip control and best surface quality in steels and cast iron. The KenReam S solid carbide reamer series are designed for long tool life and highest metal removal rates in blind . $1.38

0 · when to use a reamer

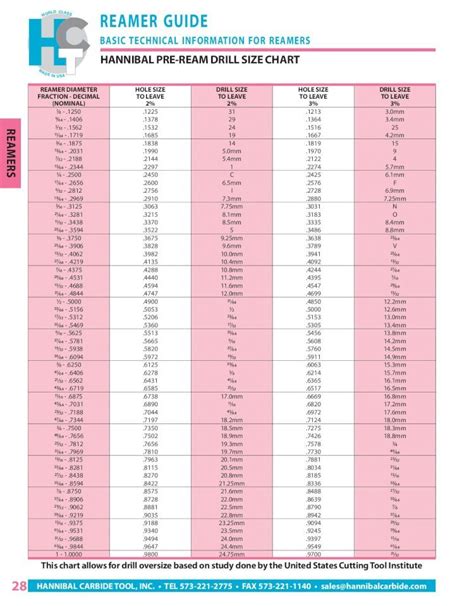

1 · recommended drill size for reamers

2 · reamer size chart

3 · how should reamers be treated

4 · hand reamer vs machine

5 · drill size for 10mm reamer

6 · drill and reamer diameter chart

7 · cnc reaming uses

In this article, you will learn the 9 different types of sheet metal operations with diagrams. Also, you can download the pdf file of this post. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication.

Reamers are a great finishing tool for smoothing the surface of a hole. Precision reamers are designed to only increase the size of the hole by a small amount. Controlling Hole Sizes & Finishes

Solid carbide reamers for highest feed rates, maximum chip control and best surface quality in steels and cast iron. The KenReam S solid carbide reamer series are designed for long tool life and highest metal removal rates in blind . Simply put, a reamer is a multi-tooth, rotary cutting tool that removes relatively small amounts of material along its leading edges as it passes. It is considered a finishing tool, and requires a pre-drilled hole of a specific .

Discover Fullerton's carbide reamers: the epitome of swift precision. Crafted for diverse reaming needs, they master materials from tough titanium to delicate wood. Ready in a flash for aerospace, automotive, and more, Fullerton .Reamers are a great finishing tool for smoothing the surface of a hole. Precision reamers are designed to only increase the size of the hole by a small amount. Controlling Hole Sizes & Finishes

Solid carbide reamers for highest feed rates, maximum chip control and best surface quality in steels and cast iron. The KenReam S solid carbide reamer series are designed for long tool life and highest metal removal rates in blind hole and through hole applications up to 5xD. Learn more about different types of reamer tools and how they are used in manufacturing. Reamer is the family name for the highest-precision tools in wide use. They allow basic machines and even hand work to produce holes within a tolerance of 0.0002 inches. Whether it’s a straight-flute reamer for through-holes or a spiral-flute reamer for blind holes, understanding the distinct characteristics of each type can make all the difference in achieving optimal performance. Simply put, a reamer is a multi-tooth, rotary cutting tool that removes relatively small amounts of material along its leading edges as it passes. It is considered a finishing tool, and requires a pre-drilled hole of a specific diameter to function properly.

Discover Fullerton's carbide reamers: the epitome of swift precision. Crafted for diverse reaming needs, they master materials from tough titanium to delicate wood. Ready in a flash for aerospace, automotive, and more, Fullerton merges quality and quickness flawlessly.

CNC reaming can offer a better surface finish with its precision grinding capabilities, creating holes of specific sizes and accurate diameters. Processes such as drilling and boring come before reaming metal as they must prepare the hole before reaming. CNC Machining Exotic Alloys: When machining Inconel, titanium, and other high-cost materials, reaming your hole is important to ensure that the desired finish specification is met. With reamers, a machinists can better predict tool life, . CNC reaming uses precise numerical control technology, utilizing reamers to perform minute cutting on the workpiece hole wall to achieve high precision and high surface finish. This article will delve into the working principle, applications, advantages, and disadvantages of reaming.

Reamers are precision tools designed to finish holes to a high degree of accuracy and surface finish. Think of them as the fine-tuners in the world of metalworking and machining. Their primary function isn’t to create new holes but to refine and perfect pre-drilled ones.

Reamers are a great finishing tool for smoothing the surface of a hole. Precision reamers are designed to only increase the size of the hole by a small amount. Controlling Hole Sizes & FinishesSolid carbide reamers for highest feed rates, maximum chip control and best surface quality in steels and cast iron. The KenReam S solid carbide reamer series are designed for long tool life and highest metal removal rates in blind hole and through hole applications up to 5xD. Learn more about different types of reamer tools and how they are used in manufacturing. Reamer is the family name for the highest-precision tools in wide use. They allow basic machines and even hand work to produce holes within a tolerance of 0.0002 inches. Whether it’s a straight-flute reamer for through-holes or a spiral-flute reamer for blind holes, understanding the distinct characteristics of each type can make all the difference in achieving optimal performance.

Simply put, a reamer is a multi-tooth, rotary cutting tool that removes relatively small amounts of material along its leading edges as it passes. It is considered a finishing tool, and requires a pre-drilled hole of a specific diameter to function properly.Discover Fullerton's carbide reamers: the epitome of swift precision. Crafted for diverse reaming needs, they master materials from tough titanium to delicate wood. Ready in a flash for aerospace, automotive, and more, Fullerton merges quality and quickness flawlessly. CNC reaming can offer a better surface finish with its precision grinding capabilities, creating holes of specific sizes and accurate diameters. Processes such as drilling and boring come before reaming metal as they must prepare the hole before reaming.

how to move my electric light ceiling box

CNC Machining Exotic Alloys: When machining Inconel, titanium, and other high-cost materials, reaming your hole is important to ensure that the desired finish specification is met. With reamers, a machinists can better predict tool life, . CNC reaming uses precise numerical control technology, utilizing reamers to perform minute cutting on the workpiece hole wall to achieve high precision and high surface finish. This article will delve into the working principle, applications, advantages, and disadvantages of reaming.

when to use a reamer

Widely used in commercial, industrial, residential, and commercial applications, these flat and compressed forms of metals offer diversity in terms of functions and use. That being said, each sheet is prepared carefully using different types of metals and manufacturing processes to stand out from the others.

cnc machine reamer|hand reamer vs machine