cnc lathe machine uses With a CNC lathe machine, parts for other equipment can be made more efficiently, along with a vast array of other items. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and . $108.00

0 · types of cnc lathe machines

1 · lathe machine block diagram

2 · cnc turning lathe machine

3 · cnc lathe machine diagram

4 · cnc lathe for beginners

5 · cnc lathe explained

6 · cnc lathe and milling machine

7 · basics of lathe machine

If your home’s tap water tastes metallic, it doesn’t necessarily mean that it poses a health risk. The safety of your home’s water depends on what is causing the metallic taste. For example, even though iron gives off a strong metallic taste, it is not known to cause any health problems in the people who consume it.

types of cnc lathe machines

What is a CNC lathe machine used for? A CNC lathe machine is primarily used for metal shaping and producing precision parts . These machines can shape metals, alloys, and even some plastics into various components.

A CNC lathe uses computer control to automate the machining process. This . CNC Lathe machines with 6 or more axes represent the pinnacle of machining flexibility and precision. These lathes can manipulate the workpiece and the tool in multiple directions simultaneously, offering unparalleled . With a CNC lathe machine, parts for other equipment can be made more efficiently, along with a vast array of other items. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding and .

machining cnc precision

lathe machine block diagram

A CNC lathe is a machine that uses computer-controlled cutting tools to create parts in various dimensions. While there are many different types of CNC lathes, milling machines .

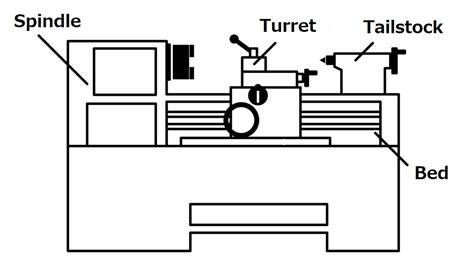

A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe . A lathe machine is a type of versatile machine tool used in CNC services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, . A CNC lathe machine is a powerful tool used to shape and cut materials, primarily metals, into precise cylindrical forms. Unlike traditional manual lathes, CNC lathe machines . What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far .

At its core, a CNC lathe is a computer-controlled machine tool designed to shape and manufacture cylindrical parts with unprecedented precision and accuracy. This marvel of modern engineering eliminates the need for manual .

What is a CNC lathe machine used for? A CNC lathe machine is primarily used for metal shaping and producing precision parts . These machines can shape metals, alloys, and even some plastics into various components. CNC Lathe machines with 6 or more axes represent the pinnacle of machining flexibility and precision. These lathes can manipulate the workpiece and the tool in multiple directions simultaneously, offering unparalleled capability in creating highly complex parts.A CNC machine produces a product using coded instructions, without manual operation of the machine. These machines can be varied in size, function and design, and include lathes, milling machines and multi-axis machines. In this article, we will answer the question, “What is a CNC lathe machine?”

With a CNC lathe machine, parts for other equipment can be made more efficiently, along with a vast array of other items. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding . A CNC lathe is a machine that uses computer-controlled cutting tools to create parts in various dimensions. While there are many different types of CNC lathes, milling machines are used when you need to cut shapes by removing material from an item; turning machines work when you need to cut shapes by taking material away from the outside edges.A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool.

machined aluminum cnc precision turned factory

A lathe machine is a type of versatile machine tool used in CNC services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, lead screw, feed rod, leg, saddle, apron, carriage, and chip pan. 1. Turning.

A CNC lathe machine is a powerful tool used to shape and cut materials, primarily metals, into precise cylindrical forms. Unlike traditional manual lathes, CNC lathe machines are automated and controlled by computer programs, allowing .

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.

At its core, a CNC lathe is a computer-controlled machine tool designed to shape and manufacture cylindrical parts with unprecedented precision and accuracy. This marvel of modern engineering eliminates the need for manual intervention in the machining process, thereby improving productivity, consistency and repeatability.What is a CNC lathe machine used for? A CNC lathe machine is primarily used for metal shaping and producing precision parts . These machines can shape metals, alloys, and even some plastics into various components. CNC Lathe machines with 6 or more axes represent the pinnacle of machining flexibility and precision. These lathes can manipulate the workpiece and the tool in multiple directions simultaneously, offering unparalleled capability in creating highly complex parts.A CNC machine produces a product using coded instructions, without manual operation of the machine. These machines can be varied in size, function and design, and include lathes, milling machines and multi-axis machines. In this article, we will answer the question, “What is a CNC lathe machine?”

With a CNC lathe machine, parts for other equipment can be made more efficiently, along with a vast array of other items. Regardless of their unique functionalities, the primary task of CNC lathe machines involves holding . A CNC lathe is a machine that uses computer-controlled cutting tools to create parts in various dimensions. While there are many different types of CNC lathes, milling machines are used when you need to cut shapes by removing material from an item; turning machines work when you need to cut shapes by taking material away from the outside edges.

A CNC lathe uses computer control to automate the machining process. This means it follows pre-programmed instructions for cutting, drilling, and shaping parts. In contrast, a normal lathe requires manual operation, where the machinist manually guides the cutting tool. A lathe machine is a type of versatile machine tool used in CNC services, the basic parts of a turning lathe including headstock, spindle, chuck, tool post, compound rest, cross slide, tailstock, hand wheel, guideway, bed, lead screw, feed rod, leg, saddle, apron, carriage, and chip pan. 1. Turning. A CNC lathe machine is a powerful tool used to shape and cut materials, primarily metals, into precise cylindrical forms. Unlike traditional manual lathes, CNC lathe machines are automated and controlled by computer programs, allowing .

What Is A CNC Lathe Machine? A CNC lathe is a machine that has a spindle that holds a workpiece. Lathes drive their set of cutting tools over two different axes. These axes are known as X and Z. Many lathes feature far more functionality than just this though.

cnc turning lathe machine

Bracket as shown. The top of the bracket should be 13” from the ground or 11” from the bottom of the gate as shown. Fasten the bracket with (2) 11/4” Black Stainless Steel Screws. Insert the Drop Rod into the top bracket and insert the rod into the bottom bracket as shown. Measure 4” between the brackets and fasten with (2) 1/2” black

cnc lathe machine uses|types of cnc lathe machines