sheet metal plug weld size Plug welding is a type of welding where the weld is in the shape of a plug. This type of welding is often used to join two pieces of metal together, such as when joining metal pipes. What is the difference between a spot weld .

Buy ZVex Effects Vexter Box of Metal Distortion Guitar Effects Pedal: Distortion & Overdrive - Amazon.com FREE DELIVERY possible on eligible purchases

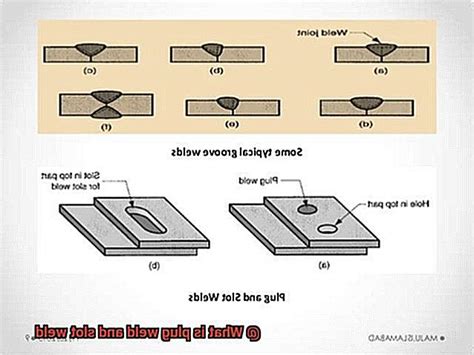

0 · welding symbol for plug weld

1 · plug welding techniques

2 · plug weld vs slot

3 · plug weld vs fillet

4 · plug weld size chart

5 · plug weld not completely filled

6 · plug weld in steel structure

7 · plug weld hole size chart

Zinc plating, called metallization, is a method of coating steel with zinc for protection. The process involves submerging the steel part in a solution with zinc salt and applying an electric current in the tank to make zinc ions migrate and coat the surface of the steel.

welding symbol for plug weld

The minimum center to center spacing for plug welds shall be 4 times the diameter of the hole. The minimum center to center of slot welds (traverse direction (this way II) shall be . A plug weld, or rosette weld, is a welding method that joins overlapping metal sheets by filling pre-cut circular holes with molten metal, creating strong, discreet joints. Widely used in automotive and construction . Plug welding involves joining two overlapping sheets of metal by welding through the top sheet to the bottom sheet, creating a strong and concealed bond. This method is commonly used in automotive and sheet . Plug welding involves filling a hole or slot in one metal plate with molten metal from the other plate to create a sturdy joint. On the other hand, slot welding involves cutting a slot in one piece of metal and welding it to another .

Stick welding of sheet metal shall be carried out using AWS A5.1/A5.1M E6013 (CWB/CSA W48-06 E4313) type electrode of diameter 5/64 inch or 2.0 mm. E6013 types electrode offer very good arc stability, easy-to . Plug welding is a type of welding where the weld is in the shape of a plug. This type of welding is often used to join two pieces of metal together, such as when joining metal pipes. What is the difference between a spot weld .

2007 fusion smart junction box

The strength of a plug weld is essentially based on the circumference of the weld around the hole, times the fillet weld size cap’y. If you want to be conservative take the . Vehicle makers may have recommendations for plug weld hole size and location. If they do not, holes should be 8 millimeters or 5/16 inch if the flange width will support it. Follow OEM welding requirements, including what nugget . Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, seam/fillet welding, MIG welding, and TIG welding, each with unique applications and . The kit includes three sizes of 18 gauge plugs to allow you to fill various sizes of holes. The step drill bit and plugs are designed for a precise fit. Simply drill the hole to the size plug you wil be using for a perfect fit. (10) .

Testing plug weld hole sizes to see which is best on sheetmetal What size plug weld should be used for 1/8" steel? I'll be repairing the rotted frame (fully boxed 2"x4"x1/8") on my 98 Wrangler in a few weeks using Safe-T-Caps (1/8" thick U-shaped channel that slides over the bottom and sides of the frame rail, for those not familiar). The manufacturer only instructs to weld around the perimeter of the cap, but I'd like to add some .

These 14-gauge welding discs are designed to fill the holes left over from shaving body trim, smoothing firewalls, or even that little rust spot in a body panel. This 29-piece kit includes sheet metal patches in several conventional hole sizes. The patch itself is slightly undersized to allow it to fit cleanly into the hole, however, the real icing on the cake is the tabs surrounding each . In this video I show you how to set up your MIG welder and also prepare your metal for the plug welding process. I try to walk you through the entire process. Per AWS D1.1 The minimum diameter of the hole for the plug shall be no less than the thickness of the part containing it plus 5/16(8mm) preferably rounded to the next greater odd 1/16". The maximum width shall equal the minimum width plus 1/8"(3mm) or 2-1/4 times the thickness of the member,which ever is greater. For slotted holes it is the same as above . Plug Welding. Honda does not indicate a specific plug weld nugget size in their collision repair information. Per the Honda/Acura Body Repair Basic manual, MAG Welding - Plug Welding - Body Basic: "This section provides a chart on what size hole will need to be drilled depending on the metal thickness. To determine the thickness of the parts .

Here's a quick video on how to plug weld sheet metal using mig without blowing yourself a bigger hole than you started with. My names Matt Urch and I own an.

Weld Symbol: A small circle or dot is placed at the intersection of the reference line to indicate the location of the puddle weld. Weld Size: The size or diameter of the puddle weld is indicated by placing a dimension value alongside the weld symbol.This value specifies the desired size of the weld in inches or millimeters. Additional Specifications: Additional .

Plug Welding. Plug welding, also known as hole welding, involves joining two metal pieces by filling a hole in the top piece with weld material, which then fuses with the bottom piece. This method creates a strong, durable bond and is commonly used in automotive and manufacturing applications. Spot Welding These 12-gauge welding discs are designed to fill the holes in the heavier gauge metal areas of a car, including the frame and any weight-bearing floor ; This 29-piece kit includes sheet metal patches in several conventional hole sizes ; 12-gauge steel (approximately 0.1046" or 7/64") Tabs around disc allow for strong butt-weldStudy with Quizlet and memorize flashcards containing terms like The edge weld symbol has many of the elements applied to other weld symbols—size, length, pitch, weld-all-around, weld-in-field, finishing and methods of finishing welds., Dimensions that may be added to the edge weld symbol are size, length, and spacing (pitch of intermittent welds)., The edge weld symbol may .

plug welding techniques

Matt,Just to be clear ..spot or plug welds are only used on the perimeter to fasten the panel to the inner structure.If you did a repair to the inner structure itself by replacing a section , the seam should be a continuous weld ,then epoxy primed..just like doing a repair on the body skin .there should be no need for a body sealer if there wasnt any there before. Plug welds are complete; I used a 5/16 in. hole. Some of the plugs turned out ok; the others didn't turn out quite like I would have hoped. Even with sheet metal screws in place to draw the two pieces of metal tight together, I experienced some separation when I .

This is a scaled down example, but sheet metal manufacturing size is the limitation which requires that arrangement. I'm just trying to see if SolidWorks can recreate what is actually being manufactured . Choose the appropriate weld . Comprehensive 29-Piece Kit: The kit includes a total of 29 sheet metal patches in multiple conventional hole sizes, ensuring you have the right size for your specific hole-filling needs. Strong and Durable Construction: . Learn how to select the right screw size for your spot welding applications and ensure strong, secure joints in sheet metal. 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: 9:00am–18:00pm. Since the duration of welding a stud weld is mere second(s), the workpiece may not be ready to accept a sudden and huge temperature change to produce a weld puddle that can melt all 3 pcs. involved in the weld, therefore producing a week and brittle fusing between the mig wire and its surrounding area.

A plug weld, or rosette weld, is a welding method that joins overlapping metal sheets by filling pre-cut circular holes with molten metal, creating strong, discreet joints. Widely used in automotive and construction industries, plug welds offer strength and . Welding sheet metal often requires a beautiful, smooth weld line. You can only achieve that naturally with a TIG welder. . So, ensure you use an abrasive type and grit size that gives you the desired finish. To remove stainless steel discoloration from welding, you can use stainless steel wire wheels and a 360-grit or coarser abrasive. .

5 Plug Welding. 5.1 Considerations for plug welding; 6 Seam/Fillet Welding. 6.1 Considerations for seam/fillet welding; 7 MIG Welding. 7.1 Considerations for MIG welding; 8 TIG Welding. 8.1 Considerations for TIG welding; 9 Sheet Metal Part Design for Manufacturing Tip. 9.1 CORNERS AND WELDING; 10 Sheet Metal Fabrication Welding FAQ

The tables advise fillet weld size based on a strength weld or joining weld (rigidity weld). See also Plug Welding Complete Guide: Everything you want to know AWS has also suggested the minimum fillet weld size in AWS D1.1. in the below table you can find the recommended minimum fillet weld size by the AWS. Plug welds 5/16 18 gauge 0.23/CO2 26-30psi e formation and sweeping left to right. I think I'm moving too fast, but also deal with hand/arm tremors. . you might also try some .030 size, probably E70S-6. at lower speed and perhaps increased voltage to get higher temperatures at the arc, rather than just more heat (more same-hot metal .

Aim for the center of your plug weld, and let the hot puddle melt the sheet metal. Start by welding one edge of the hole, and swirl it around, keeping toward the center of the hole. You want the puddle to melt the sheet metal, not the arc, for this. It will be a bit squirrely at first, but just let the puddle do the work Plug Weld Hole Size Calculation-Example: 1/4″ steel would be equivalent to .25″ . Spot welds are where two pieces of sheet metal are pressed together really tight. After clamping the two, a spot welder is used to join the two metals together by running a current through both metals. This current melts the two metals together without the . Buy Weld-In Patch Plug Kit, 11-18 Gauge: Depth - Amazon.com FREE DELIVERY possible on eligible purchases . 29-Piece Kit with Multiple Hole Sizes, Universal Fit, Welding Discs for Body Trim Shaving and Rust Repair. . Eastwood Sheet Metal Plug Hole Kit to Fill Various Sizes of Hole with Plastic Case. 4.7 out of 5 stars .

plug weld vs slot

3/16 or 5/16 holes for sheet metal plug welds 11-01-2006, 07:46 PM. Looking at getting an air flange/punch tool and just wondering what sized punch works better for sheetmetal. The 3/16 sized punches are cheaper but is it large enough for 18-22 guage flange joints/plug welds? What about 16 gauge?

plug weld vs fillet

You can scan the CCTV junction boxes and they will add the visual tablet map of the area to your b.o.b. +++ You can also scan enemies for LOOT, as well as any containers. Doors and animals can.

sheet metal plug weld size|plug welding techniques