forming metal into square boxes Watch as we expertly stamp and shape steel into perfectly crafted boxes, sh. Experience the mesmerizing process of steel box forming in this satisfying video! Get VA Distribution Box 8x75-125mm at wholesale prices at Rexel UK - your electrical distributor. Join Now!

0 · sheet metal box steps

1 · sheet metal box making tips

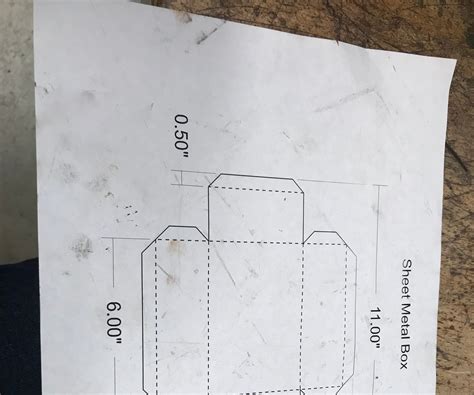

2 · sheet metal box layout

3 · sheet metal box fabrication

4 · sheet metal box design

5 · how to make sheet metal boxes

6 · how to fabricate sheet metal box

7 · how to cut sheet metal box

Ventilation and Heat Dissipation - This vented outdoor enclosure box will come with a 12v cooling fan (80x80x10mm), and there are 2 ventilation slots on each side, which helps to dissipate the heat quickly. In addition, there are also 3 holes are drilled at the bottom of the electrical junction box for entering cold air or pass through the cables.

Fabricating a sheet metal box requires careful planning, precise cutting, skilled forming and bending, accurate joining, and meticulous finishing. The process involves transforming a flat metal sheet into a functional and .In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my .

To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as .Fabricating a sheet metal box can be a rewarding DIY project or a valuable skill for professionals. In this comprehensive guide, we'll walk you through the step-by-step process of creating a . Watch as we expertly stamp and shape steel into perfectly crafted boxes, sh. Experience the mesmerizing process of steel box forming in this satisfying video!

Fabricating custom sheet metal boxes involves a variety of techniques and processes to transform the raw material into the desired form. Welding, riveting, and fastening methods are commonly employed to join the . Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake . How To Make a Sheet Metal Box - Shop Class Project. This is another great beginner sheet metal project I use in my shop classes. I use it to teach print reading skills and . Sheet metal boxes are a versatile and essential component in various industries, ranging from automotive to electronics. This comprehensive guide will delve into the fundamentals of sheet metal boxes, their applications, .

When it comes to forming deep boxes, sheet metal fabricators face a major challenge: getting their tooling to reach inside the box. With a standard press brake, the upper beam and punch holder are at risk of crashing into the . Solutions proposed for increasing the forming limit generally fall into three categories: changing the material properties of formed metal, changing the frictional state, and changing the stress state controlled by the applied blank holding force (BHF). . It was concluded that the forming ability of the square box can be improved by using the .

Find step-by-step College algebra solutions and your answer to the following textbook question: A machine produces open boxes using square sheets of metal. The machine cuts equal-sized squares measuring 3 inches on a side from the corners and then shapes the metal into an open box by turning up the sides. If each box must have a volume of 75 cubic inches, find the length . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Find step-by-step Discrete math solutions and your answer to the following textbook question: A machine produces open boxes using square sheets of metal measuring 12 inches on each side. The machine cuts equal-sized squares whose sides meas ure 2 inches from each corner. Then it shapes the metal into an open box by turning up the sides. Find the volume of the box..

If the sides of the box were removed, the remaining corner radii could be assembled into a cup. Subsequently, the corners of the box form in a manner similar to cup drawing. Radial tension in the corners pull material into the corners with circumferential compression placed on the material moving toward the die radius.Triangle Boxes; Tubing Insulation; Wall Stack Products; Weatherproof Jacketing; . / Sheet Metal Forming Machinery / By Harry Thompson IV / December 4, 2018 . . Bending the flat piece of metal so that the square cones into a round is usually done on a 10 ft Hand Brake—that’s a lot of effort! Tennsmith Hand Brake.

Creating a 22 gauge sheetmetal box from scratch. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan . Rectangular box shells can be drawn to greater depths than square boxes. The depth of draw increases with the increasing width of the longest side. The formability diagram in Fig. 1 illustrates the relationship between the maximum depth of draw (h-max), the width of the longest side (w) and the size of the corner radius (Rc) on the number of . Rectangular box shells can be drawn to greater depths than square boxes. The depth of draw increases with the increasing width of the longest side. The formability diagram in Fig. 1 illustrates the relationship between the maximum depth of draw (h-max), the width of the longest side (w) and the size of the corner radius (Rc) on the number of .

sheet metal box steps

Channel Rolling Easy Way. Channels Roll Easy Way. This is 8" x 15ppf channel rolled the easy way, leg in, to a 36 foot radius. At Jorgenson Metal Rolling & Forming, we specialize in structural shape rolling.We do angle iron rolling, steel channel rolling, beam rolling, pipe rolling as well as square and rectangular tube rolling. The junction box was fed with romex and the ground wire was cut off. The hot had rubbed into the side of the metal 4 square box. As soon as I reached out touched this metal box, every aspect of poor bonding practices went through me. Think of it that way.

rectangular metal box with cover

The blank is initially square, 200 mm by 200 mm, and is 0.82 mm thick. The rigid die is a flat surface with a square hole 102.5 mm by 102.5 mm, rounded at the edges with a radius of 10 mm. The rigid square punch measures 100 mm by 100 mm . Have an issue with a bronze material that I can only get in sheet form. I'd like to rip it into square's and then get it into round stock form. We're looking at lengths of 28", and diameters of 0.500". Talked to a centerless grinder and he .

The multi-objective robust optimization of NUMISHEET’93 square box drawing is carried out by using the proposed process. Compared with the deterministic optimization results, the standard deviation of the thinning and the wrinkling index of the robust design are reduced by 41.5% and 18.1% respectively, and the robustness of forming quality is . I shall give you an example: You can run conduit into the side knockouts of a box and the back of the box. You really cannot run a conduit into the ends of a box unless it is a rectangular object like a gutter for instance. . The blank holder force (BHF) was applied on sheet metal independently and effectively by the binder which was divided into double rings. . method is proved by taking the non-axisymmetric square box as an example. . in the application of blank-holder force towards improving the forming limits of sheet metal parts. J Mater Process Technol 75 .Metal C-Channels & Box Channels. Since 1948, Johnson Brothers has manufactured Metal channels including C Channels & Box Channels. We also specialize in Open Seam Tubing including Square Tubing, Square Steel Tubing, Rectangular Tubing, and Rectangular Steel Tubing. Channel and Box Channel: Types of Metals

Can use base metal, silver or gold. Works well. Best way to work the metal into place. Works best with wire gauges 16,18,20,22. 24 gauge wire is a bit thin for what I'm currently doing. I'd recommend this to anyone working with metal wire for jewelry purposes. Has oval, triangle square and circle with handle to help hold. Great product! Very . Rectangular box shells can be drawn to greater depths than square boxes. The depth of draw increases with the increasing width of the longest side. The formability diagram in Fig. 1 illustrates the relationship between the maximum depth of draw (h-max), the width of the longest side (w) and the size of the corner radius (Rc) on the number of .- Nonmetallic sheathed cable (Type NM)—a factory assembly of two or more insulated conductors having an outer sheathing of moisture-resistant, flame retardant, nonmetallic material. It is available with two or three conductors in sizes from 14-AWG through 2-AWG copper and 12-AWG through 2-AWG aluminum. - Underground feeder cable (Type UF)-used for underground .Sheet metal boxes are versatile and functional, serving a variety of purposes across industries such as electronics, automotive, and HVAC. . A straight edge or T-square . A scribe or fine-tip marker . A center punch . A hammer . . Sheet Metal Fabrication is the process of forming metal sheets into structures or parts using various .

The Box Rib Wall Panel Roll Forming Machine is designed to produce high-strength, durable wall panels with a distinctive box rib profile, ideal for industrial, commercial, and agricultural buildings. These panels offer excellent structural performance and aesthetic appeal, making them popular in modern construction. The machine forms metal sheets into precise . A novel segmental blank holder technique was developed to apply BHF on sheet metal, in which the binder was divided into double rings to apply blank holding force (BHF) independently and .

machine designed to bend sheet metal to form edges and prepare the metal for wired edge. Seam can also be formed on this machine. . machine designed to bend all four sides of the sheet metal box. Cornice Brake. machine capable of forming sheet metal sections many feet in length. When fitted with forming blocks, it an produce various shapes in .

Splenor Tools Steel 1" Square Dapping Doming Block and 12 Punch Set - for Jewelry Making - Metal Forming Tools - Shaping Die. 3.7 out of 5 stars . 2.5 Tons Press Bending And Create Up To 90 Degree, High Flexibility, Easy Operation Sheet Metal Forming Bender. 4.0 out of 5 stars. 90. 1.99 $ 121. 99. FREE delivery Mon, Sep 30 . Or fastest .Sheet Metal 2 Learn with flashcards, games, and more — for free. . The long arm of the steel square is the tongue. False. Numbers on the bottom edge of a steel circumference rule are used for finding the circumference of a circle or cylinder. True. Sheet metal workers commonly use a _____ scratch awl for general-purpose work.

sheet metal box making tips

Because material forming the sides of the box can flow more freely than material forming the corners, metalformers often add draw beads to the blankholder in these areas to further control and direct material flow. Without draw beads, excess material can flow into the sidewalls of the box to create undesirable buckles and waves.

sheet metal box layout

Scherer Metals has been Colorado's leader in custom architectural metal fabrication for over 120 years.

forming metal into square boxes|sheet metal box fabrication