forming ribs in sheet metal Incorporating ribs, flanges, and hems into flat sheet metal augments the structural integrity and adds to the overall utility and aesthetic of the metal part. Strengthening with Ribs. . The fundamental processes in sheet . Whether you have a weekend project, or a whole house to wire, you'll find the products you need at prices that will keep you under budget.

0 · sheet metal strengthening ribs

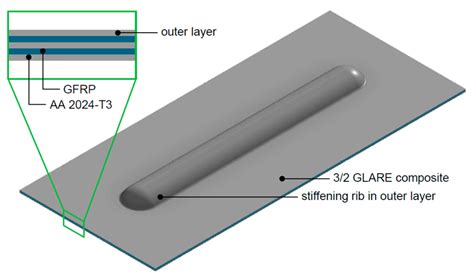

1 · sheet metal stiffening rib design

2 · sheet metal stiffening rib

3 · sheet metal rib design guidelines

4 · sheet metal design guideline pdf

5 · how to stiffen sheet metal

6 · hemmed edge sheet metal

7 · classic rib metal roofing panel

B-Line series electrical Type 3 and 3R junction boxes are used as wiring boxes, junction and pull boxes. For additional information, view or download the Type 3 and 3R enclosure section of the B-Line series electrical enclosure catalog. Explore other Eaton solutions.

sheet metal strengthening ribs

Form features in close proximity to each other increase forming strain which may cause “oil canning” or other deformation, fracturing or material separation. PRO TIP: Gusset and rib combinations require high-cost tooling, secondary trimming and progressive forming. Mate has two ways to add strengthening ribs: Mate’s Rollerball™ tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness . The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal parts without a secondary operation. It is available in popular tool st.Stiffening Rib Mode: Forms the sheet metal to create a rib that can be used to stiffen the sheet metal to reduce sheet flex. This is particularly helpful in large unsupported panels. Allows fabricator to reduce sheet metal thickness without compromising the strength and rigidity of the product; Eliminates secondary brake press or welding .

Incorporating ribs, flanges, and hems into flat sheet metal augments the structural integrity and adds to the overall utility and aesthetic of the metal part. Strengthening with Ribs. . The fundamental processes in sheet .Amico 27 in. x 97 in. Domestic Stay Form Metal Rib Forming Sheet. MFG#: 1150001. SKU#: 62700530AA. .99 (EACH) Share. Add to List. Select your local branch for best pricing and delivery options. Orders ship in 1-3 business days. 1-800-944-8322. Canadian Customers Visit WhiteCapSupply.com.Metal Rib Expanded metal sheet for leave-in-place concrete forming applications Reduces labor and material costs compared to traditional forming methods for wall joints and “buried” applications. Saves cycle time because the sheet remains in place, only supports and bracing are removed, and form stripping is eliminated.

The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh are embedded in the structure, providing a rough surface for subsequent concrete placement. Features:a method of forming dove-tailed ribs in sheet metal which, consists in forming a rib with walls at right angles to the sheet and with. a portion intermediate its walls bent inward toward the sheet sufiiciently to form an angle between the inwardly bent portion and the said right angle wall materially smaller than the same angle in the com' pleted article, and compressing the .• Retains surrounding soil while forming below grade structures • Permits water to run out of formwork during concrete pour Stay-Form® is produced from hot-dipped galvanized sheet steel per ASTM-A653 V-Ribs 3/4” deep and 3 7/8” on center Sheet size 27” wide x 96” long* (18 sq. ft. per sheet) Pallet 250 sheets per pallet (4500 sq. ft.) Using the Rollerball tool is also a better option than using a standard forming tool to make the ribs. Standard forming tools may require tens to hundreds of hits and several minutes to produce strengthening ribs over the length of a sheet. Mate Rollerball reduces machine time to seconds and produces a better looking end result.

Roll Forming Process: Roll forming is a continuous process that involves passing a flat metal sheet or coil through a series of rollers, each with a specific shape. These rollers progressively bend and shape the metal into the desired profile, in this case, the Ag Classic Rib.RIB Entire section must be restrained flat while forming with custom tooling. DESIGN TIPS • Close proximity form features can cause secondary operations after forming and adds to manufacturing cost. • Form features in close proximity to each other increase forming strain which may cause “oil canning” or otherA110 - Metal Rib Tech Data Sheet; Handbooks. . A110 - Metal Rib Accessories | Wall Forming Accessories | Light Forming Products Dayton. Stay-In-Place Formwork for Concrete A110 Metal Rib is the formwork solution for tough forming situations. It can be cut in the field with tin snips, and be bent to form curves. Metal Rib is versatile enough .

I'm having trouble putting a rib into a sheet metal part for strength. I would like to put it in along the 90 deg bend in the middle about a 1/4 inch deep. Not sure how to go about doing it. . Use a forming tool to apply the rib. Has to be a sheet metal part There are some samples with Solidworks Gabe Cruz. Answered on 8 May, 2013 01:05 PM .A basic (single axis) bend is the most foundational sheet metal forming operation. Despite the relative simplicity of the bending process, there is a lot to consider as a designer. . Corner Ribs. To add bending stiffness to a bend, ribs can be created by pressing a v-notched tool perpendicular to the bend axis. This technique is commonly seen .

Live Stream — How I would create a rib forming tool with Sheet metal.Style: Casual Time: About 15-30 minutes (We all have other things to do :-)Fusion 360 fo.

A method of forming intersecting stiffener ribs in a flat sheet metal panel so as to rigidify the panel and prevent it from flexing along mutually perpendicular axes by cutting one or more slit means at a predetermined location on the sheet, each slit means being defined by a pair of spaced side edges of equal length and originating from a common point, forming an elongated rib shaped .

This document discusses various sheet metal forming processes. It describes cutting processes like shearing, blanking, and punching. . Creates indentations in sheet, such as raised (or indented) lettering or strengthening .

Introduction of special bending tool "Stiffening rib forming" for Bystronic Pressbrakes.Learn more: https://www.bystronic.com/en/products/pressbrakes/press-. Ribs and Offsets. Rib and offset tools add strength and stability to sheet metal components. In many situations, adding stiffening ribs may allow the use of thinner materials, resulting in material cost savings. These tools come in two varieties: single-hit and continuous. Metal Rib Expanded metal sheet for leave-in-place concrete forming applications This leave-in-place sheet is typically used to form footings, bulkheads, grade beams, pile caps and blindside walls. The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh .A blank holder must always be used in sheet-metal drawing to hold the flat blank as it is being drawn into the die cavity. False. 1 / 15. 1 / 15. Flashcards; Learn; . such as raised letter or strengthening ribs. Embossing. . Which two of the following processes are classified as high‑energy‑rate forming processes.

Compared to traditional methods utilizing progressive forming tools, Mate Roller Solutions promises to dramatically increase productivity when creating detailed forms. Tooling configurations include: • Rolling rib--creates stiffening ribs in any contour, starting and ending anywhere on the sheet.

sheet metal stiffening rib design

The nose rib offers a good example of forming a curved flange because it incorporates both stretching and shrinking (by crimping). They usually have a concave flange, the inside edge, and a convex flange, the outside edge. . Sandbag bumping is one of the most difficult methods of hand forming sheet metal because there is no exact forming .ribs and comparatively thin walls, which are difficult to machine. Sheet-forging technology has been proposed to manufacture these complex thin-walled structures. The sheet-forging process is designed to fabricate sheet material; it combines a forging method with sheet metal forming, and forging can well control the thickness and

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. SOLIDWORKS includes some example forming tool parts to get you started. SolidWorks Sheet Metal Tutorial for Beginner - 2 | Closed Corner, Welded Corner, Break Corner, Corner Trim, Forming Tool. This tutorial shows how to create f.Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of the

que es mejor brackets metalicos o esteticos

Tyco electronics and NSI make UL listed splice kits that can be hidden in wall. 334.40 I worked on two 30 unit modular apartment buildings with 39 sections the size of small ranch house.

forming ribs in sheet metal|sheet metal stiffening rib